|

|

Your donations help keep this valuable resource free and growing. Thank you.

|

Weight transfer for stock suspensions |

Post Reply

|

Page <1234> |

| Author | |

amcenthusiast

AMC Addicted

Joined: Jul/02/2012 Location: SW Atlanta GA Status: Offline Points: 1778 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Feb/08/2020 at 1:26pm Posted: Feb/08/2020 at 1:26pm |

|

So... no, since the six and the eight engines are not much different in total weight, and since the free height of the springs is probably the same, and since the shock extension is the same, I'm not going to say "It's all about spring rate". I will say 'It's all about center of gravity' though, as I understand it. And this is an area where an AMC car can really 'shine' because some models came with torque link traction bars (keeping the commentary on track with AMX and Javelin cars, avoiding the torque tube cars) 1) You can't get the front end to rise if you don't have enough 'bite' (if you have too much wheelspin) (it really doesn't make any sense that AMC would put longer springs in the six cars; that would be 'deep coil' design... but all pre-'70 strut type front suspensions were a 'deep coil' design (regardless of engine) ...and all '70-up cars were a two ball joint 'short coil' design ~whatever, they are two different designs which were engineered for long or short coils... short coils are cheaper to make; faster to wind fewer coils and contain less metal to reduce costs) 2) The way to get more bite is by attempting to adjust what is called 'instant center'. -Instant center is an invisible place somewhere between the drive wheels and the car's center of gravity. The instant center is also called the car's 'reaction point'. The reaction point is/should be somewhere close to the car's center of gravity. That distance, how close or how far away, is leverage afforded by the geometry. The location of the instant center or reaction point applies leverage upon the car's center of gravity. Study it: Google it; 'reaction point' and/or 'instant center' ...even most of those guys trying to explain it don't absolutely know everything there is to it... (like me, I have my theories too, up for debate) Depending on where the reaction point is, this can make the front end rise or fall, the rear end rise or fall, even cause the whole chassis to twist when load is applied. The torque link cars are designed to slightly rise in the rear when acceleration load is applied and slightly drop in the rear when the brakes are applied: both done attempting to keep the car level and 'stable' under all operating conditions IE 'sports car' conditions. (the torque tube cars force the whole chassis to rise when powerbraking the vehicle, slightly more in the rear than the front, but the whole car will rise higher because the leverage from the rear axle is pushing very close to, but slightly behind the car's actual center of gravity, and since the car cannot roll (powerbraking it) it will move up instead) Intentionally avoided mention of rear left spring: yes that side 'lifts' by

torque reaction in the axle and needs a strong spring anyway. (the Dodge Ramcharger engineer's website discussed that aspect as well; chassis twist, and pointed out how to install a single traction arm on the right side of the rear axle to the frame of the car (this would be like taking both AMX torque links off and installing one large torque link on the passenger side) But the major wheelspin is well known to occur on the right rear tire. ON A street stock drag race AMX THOUGH... One might try 'staggering' the torque link preload adjustment, to see how that affects 'bite' (that'll strain the rear axle housing) One could try staggering leaf spring pinion angle shims... One might try taking one torque link off... maybe the driver side link/maybe the passenger side? (not recommending this for any street car, because this affects the brake load input to the frame as well as acceleration load) One could try using pinion angle shims: pinion yoke pointed down is more bite, pointed up is less bite (this has to do with 'calculating torque of an angle' -study in physics) One could try devising offset torque link bushings, to change the angle of the torque link arms, from the axle to the chassis: this will definitely change the car's 'reaction point' in relation to the center of gravity. If you could get away with it, you could try moving the upper torque link locations down, or move the front link locations up, to make the links more parallel with the leaf springs. -this will move the reaction point higher to pull down the chassis in the rear... too much and it can pull the axle up and lose traction by lifting the drive wheels...

|

|

|

443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc

XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

|

|

|

PHAT69AMX

AMC Addicted

Joined: Jul/07/2007 Location: West Virginia Status: Offline Points: 5919 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Feb/08/2020 at 10:49pm Posted: Feb/08/2020 at 10:49pm |

|

For a fixed given front end weight, 2 different springs rated at pounds per inch,

the lower rated spring will compress a further distance than the higher rate spring with the same given load, regardless of spring free length, the weaker spring will compress further with the same load, therefore it will lift further, allowing more travel, than the higher rate spring, will it not ?

|

|

|

|

WesternRed

AMC Addicted

Joined: Aug/03/2010 Location: Australia Status: Offline Points: 5799 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Feb/09/2020 at 6:23am Posted: Feb/09/2020 at 6:23am |

|

Couple of observations from me.

It's not just about the weight of the engine, the six cylinder engine is longer, so it's center of gravity is further forward in relation to the front axle center line than the V8. I just pulled a front spring out of by Gremlin, its loaded height with the car sitting on the ground was around 9.5". If I lift the front of the car off the ground, the spring will extend to around 12", at that point its extension is limited by the shock absorber. Once the spring is removed from the car, its free height is around 13.5". So if I were to install a lighter spring, the front of the car would sit lower and the spring would have further to extend before being limited by the shock absorber, or I could install a longer shock and the current spring could extend further. If I had a longer shock and a softer spring, I could double the effect. A lighter spring would give a lower front ride height and hence a lower center of gravity for the car, which seems to counterproductive for launch, but good for aero, so I would have a slightly more aerodynamic brick. Now for comparison, I also had a spring from a 71 AMX 360 on hand and that has an extra coil and taller free height. Both springs appear from my measuring to have the same wire diameter. Both of these springs have numbers stamped into the top coil, but they do not appear to be factory part numbers, SMH75 R1010127 for the Gremlin and B38P3112 for the AMX, not sure if these numbers mean anything to anybody. |

|

|

I've finally given up drinking for good...........now I only drink for evil.

|

|

|

|

Heavy 488

AMC Addicted

Joined: Apr/27/2019 Location: In the Status: Offline Points: 3553 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Feb/09/2020 at 7:33am Posted: Feb/09/2020 at 7:33am |

|

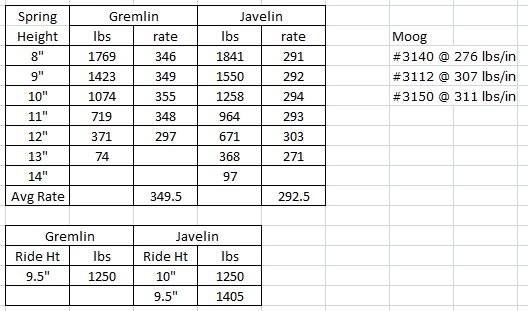

Bottom number is similar to Moog. But then any of the aftermarket used the same digits. 3 numbers for AMC front. 3112, 3140, 3156.

|

|

|

|

WesternRed

AMC Addicted

Joined: Aug/03/2010 Location: Australia Status: Offline Points: 5799 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Feb/09/2020 at 7:43am Posted: Feb/09/2020 at 7:43am |

|

Should have noticed that since I put the Moog number up earlier, would also be the spring they list for a 71 Javelin 360.

|

|

|

I've finally given up drinking for good...........now I only drink for evil.

|

|

|

|

Ken_Parkman

AMC Addicted

Joined: Jun/04/2009 Location: Ontario Status: Offline Points: 1814 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: Feb/09/2020 at 2:26pm Posted: Feb/09/2020 at 2:26pm |

|

Enthusiast - you are missing a few things. Spring design is not just about free height, and there is both load (at a specific height) and rate (load change per inch) involved. 6 (and 4) cylinder springs for a given body very much have different designs with different spring loads and rates. You can also swap springs between different weight body styles.

The six cylinder springs are lighter in both load and rate, and they do react differently to acceleration forces, and it very much can be a snowball effect. As I said do a force digram around the tire contact patch - it's educational. If you replace a 6 cylinder with a 401 in a Hornet you smash the headers by trying to drive it with the original springs and original weight. I know, I've had 5 or 6 different sets of stock springs in a Hornet learning how to tune the suspension. Here are some Javelin specs posted by Phat some time ago, you see the difference in loads and rates, and how that is multiplied from the spring to the wheel. The Javelin 8 cylinder spring 3156 has 200 lbs more load @ 9.5 and a 36 lb higher rate than the 3140 6 cylinder spring. 1970 Front Coil Spring Info from AMA Papers found at AMCyclopedia 1970 AMA Paper Specs ......... Javelin V8 ............... AMX V8 Front Coil Springs ....... STD ... A/C ... HD ..... STD ... A/C ... HD Spring Rate (Lbs/inch) ... 265 ... 285 ... 314 .... 276 ... 294 ... 322 Rate @ WH (Lbs/inch) ..... 115 ... 121 ... 133 .... 119 ... 125 ... 136 (Ratio NOT on AMA Doc) ... .425 or 2.35 (average) "WH" = "Wheel Hub" ??? .............................. Javelin SIX Spring Rate (Lbs/inch) ... 233 ... 248 ... 285 Rate @ WH (Lbs/inch) ..... 103 ... 109 ... 122 (Ratio NOT on AMA Doc) ... .435 or 2.30 (average) Material ................. SAE 5160 Install Height (inch) .... 9.75 Inside Diameter (inch) ... 5.05 Bar Diameter (inch) ...... not given Free Height (inch) ....... not given Install Ht Load (Lbs) .... not given Specs posted by another forum member: ------------------------ 1970 Javelin/AMX v8 No a/c 3112 - Front Coil Spring Inside Diameter (inch) = 5.020 Bar Diameter (inch) = .687 Install Height (inch) = 9.5 Load (lbs.) = 1591 Spring Rate (Lbs/inch) = 306.6 Free Height (inch) = 14.38 ------------------------ 1970 V8 with A/C 3156 - Front Coil Spring Inside Diameter (inch) = 5.020 Bar Diameter (inch) = .687 Install Height (inch) = 9.5 Load (lbs.) = 1690 Spring Rate (Lbs/inch) = 311.2 Free Height (inch) = 14.92 --------------------------- 1970 6 cyl with A/C 3140 - Front Coil Spring Inside Diameter (inch) = 5.020 Bar Diameter (inch) = .656 Install Height (inch) = 9.5 Load (lbs.) = 1490 Spring Rate (Lbs/inch) = 275.6 Free Height (inch) = 14.94 ---------------------------- Instant center is an engineering term, and means the center of movement for a given linkage at that instant in its travel. And yes there is some misunderstandings out there. It has absolutely nothing to do with "reaction point", and can be anywhere, even below the pavement. It does, however, affect what the suspension does with a given load, and therefore the reaction of the suspension on launch. Where this instant center is in comparison to the line of 100% anti-squat affects which way the rear suspension reacts, how far (in combination with rear spring rate), and how fast (in combination with shocks). It really gets deep if the instant center changes with the suspension movement. The cars center of gravity is very important as that is the point where the inertia loads apply, very important to the above mentioned force diagram, and very important to how the front springs react with different spring rates and the related "snowball" effect, also affected by shocks. Management of all this very much affects traction, and why the high front end theory for traction went out with the ice age.

Edited by Ken_Parkman - Feb/09/2020 at 2:56pm |

|

|

|

Ken_Parkman

AMC Addicted

Joined: Jun/04/2009 Location: Ontario Status: Offline Points: 1814 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: Feb/09/2020 at 3:17pm Posted: Feb/09/2020 at 3:17pm |

|

BTW here is the aforementioned Hornet from a shockingly long time ago. The car has been gone for 20 years, that race was from 93. Someone, I don't know who, posted the video. Back then low tens (it went 10.20s in good weather) was fast on a stock suspension. If you look at the video you can see how low the front is and how the whole car came up on launch. It would carry the right front wheel just a touch. |

|

|

|

WesternRed

AMC Addicted

Joined: Aug/03/2010 Location: Australia Status: Offline Points: 5799 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Feb/10/2020 at 9:30am Posted: Feb/10/2020 at 9:30am |

|

So in the interests of scientific research, here are a couple of springs mentioned previously, spring out of my 74 Gremlin on the left and spring out of my 71 360 Javelin AMX (360 Auto AC) on the right.

Possibly the Gremlin spring has just had a coil cut off for lowering purposes. Anyway, off to work we went.  I did have a small problem in that I forgot to reduce the sampling rate from 100 Hz, so had bout 35,000 data points to wade through for each spring, essential numbers below after some de-metrification:  So my Gremlin springs are way stiff at 350 lbs/inch. I could just throw the Javelin springs in, but it looks like it would raise the front ride height by about one inch, which would reduce potential travel. 60' times are currently somewhere around 1.7-1.8

|

|

|

I've finally given up drinking for good...........now I only drink for evil.

|

|

|

|

tached_out

AMC Nut

Joined: Feb/08/2008 Location: Vancouver, BC Status: Offline Points: 328 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Feb/10/2020 at 8:57pm Posted: Feb/10/2020 at 8:57pm |

You are wrong. Free length has nothing to do with it. Within the confines of the car they're the same working length. The difference is the spring rate. A six cylinder spring supporting a six cylinder engine will behave the same as a V8 spring supporting a V8 engine. The magic of the six cylinder spring is, with the weight of the V8 on it, the six cylinder spring will have more movement. It's no myth. It's science.

Glenn |

|

|

|

WesternRed

AMC Addicted

Joined: Aug/03/2010 Location: Australia Status: Offline Points: 5799 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Feb/11/2020 at 6:29am Posted: Feb/11/2020 at 6:29am |

|

Just a bit of an update on the identity of the SMH75 R1010127 spring posted earlier. This is the spring from my Gremlin with the 350 lbs/inch rate. Turns out R1010127 is the part number for the left front spring for an Australian assembled 1971 Rambler Matador. The springs were made by Henderson Springs in Melbourne, Australia as one of the local content parts fitted to reduce taxes at the time. I suspect the spring has been cut down when installed in the Gremlin. The Gremlin was converted from 6 cylinder to V8 in Australia years ago, so the springs were most likely changed as part of that process. The guy who did the engine swap ran a wrecking yard at the time that specialized in Ramblers .

|

|

|

I've finally given up drinking for good...........now I only drink for evil.

|

|

|

|

Post Reply

|

Page <1234> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |