|

|

Your donations help keep this valuable resource free and growing. Thank you.

|

Smoking engine |

Post Reply

|

Page <12345 7> |

| Author | |

Boris Badanov

AMC Addicted

Joined: Dec/14/2013 Location: NH USA Status: Offline Points: 4210 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 8:24am Posted: Jun/25/2019 at 8:24am |

|

To mostly agree with previous posts.

Rings failed or installed improperly tend to smoke worst when hot. But will smoke at all times. Lots of experience here from the days of leaded fuels and rings shot at 100,000 miles. Yep, if it's valve seals there will be a big puff of blue grey smoke at start up. Oh yea, if you wind it up it will smoke like the dikkens if it's rings. If all the rings are miss installed in the same way a compression test will show nothing. Many many moons ago I saw a Ford 302 pulled apart to show some attentive builder left off the oil rings... Edited by Boris Badanov - Jun/25/2019 at 8:26am |

|

|

Gremlin Dreams

|

|

|

|

vinny

Supporter of TheAMCForum

Joined: Jan/05/2012 Location: Calgary Status: Offline Points: 2837 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 8:52am Posted: Jun/25/2019 at 8:52am |

|

I have nothing to add except that as a kid I had a 750 Norton motorcycle bored .020 over and it smoked right from the beginning. I took it apart and reassembled but it still smoked. It gradually got less and by the end of the summer it was good. BTW that summer no car or bike ever beat me through the 1/4 mile. It never did get an easy break in if that makes a difference.

If it was original that Ford engine may have had the rings left out from the factory. I had a 289 with only 70000 miles that had excessive blowby. All the ring gaps were lined up so obviously there was a greenhorn on the assembly line. Edited by vinny - Jun/25/2019 at 8:59am |

|

|

|

The Anti Chrysler

AMC Apprentice

Joined: Dec/02/2016 Location: WA State Status: Offline Points: 120 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 9:40am Posted: Jun/25/2019 at 9:40am |

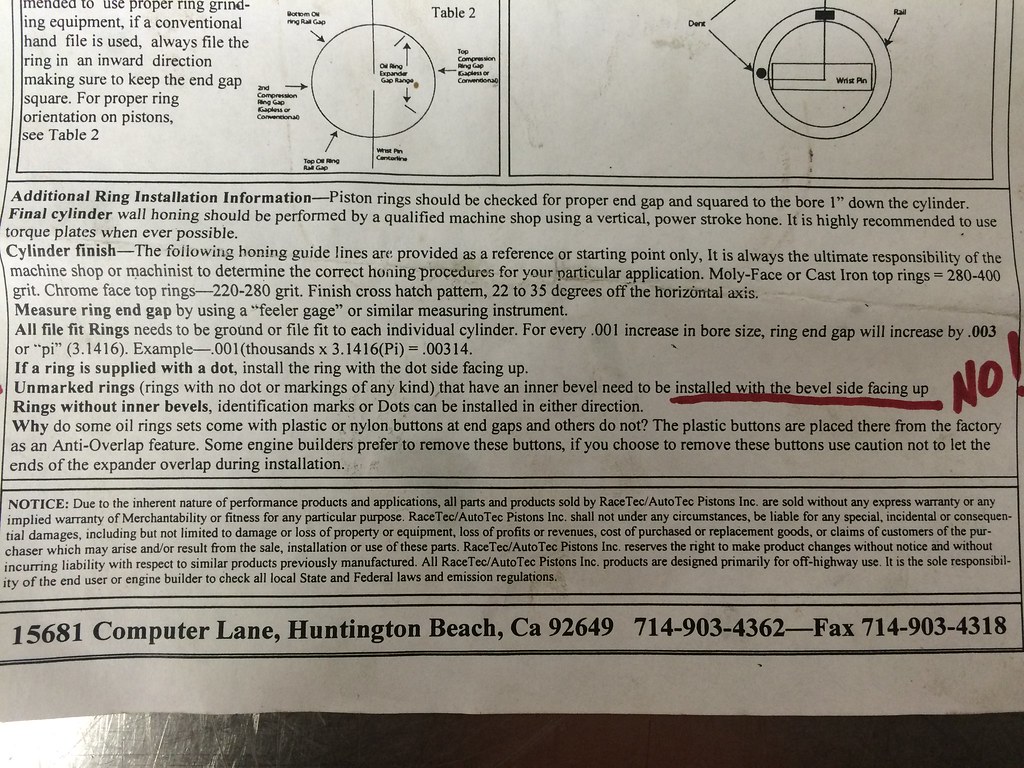

If the (faulty) instructions say to do it that way...a less experienced installer might just do that. Here's what Rick was pointing out.  Edited by The Anti Chrysler - Jun/25/2019 at 9:42am |

|

|

|

vinny

Supporter of TheAMCForum

Joined: Jan/05/2012 Location: Calgary Status: Offline Points: 2837 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 10:36am Posted: Jun/25/2019 at 10:36am |

|

It says inner bevel not outer bevel. Inner bevel up sounds good to me to give more ring surface on the bottom side on the power stroke.

|

|

|

|

Greyhounds_AMX

AMC Addicted

Joined: Nov/14/2009 Location: Kansas City Status: Offline Points: 1268 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 12:19pm Posted: Jun/25/2019 at 12:19pm |

|

An old mechanic told me that the quick way to diagnose an engine is to drive over a hill. If it smokes going up the hill it's the rings, if it smokes going down the hill it's the valve guides.

That was 35 years ago but wouldn't be too far off for this vehicle. Have someone follow you up a long hill and down the other side, and we can find out if it's high cylinder pressure situations or high vacuum situations that cause the most smoke.

|

|

|

1968 AMX 390 w/T5

|

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 12:42pm Posted: Jun/25/2019 at 12:42pm |

Actually - no - according to Perfect Circle and others - take the car out and when it's warmed up to normal temperature achieve 30 mph .......

Then accelerate to 50 mph full throttle. Do this full throttle 30 mph to 50 mph at least 10 times. The idea is that the combustion pressures of the full throttle loaded engine will force the rings against the cylinders and break things in. IF AN AUTOMATIC don't reach the point of kickdown - but do not lug it either. You want it loaded, not screaming at 5,000 RPM The factory doesn't do anything special - the rings will either be broke in within miles or they won't be and there's a problem. Waiting for rings to wear while other parts don't? Really? No oil can be formulated to “allow” the wear of only certain parts, AND to “prevent” the wear of other parts, at the same time. It has to be formulated for one or the other. The factory puts in their oil - typically synthetic, and that's that. No waiting. IF that thing was built right it will be right. Otherwise you will be waiting for a long time and hope that OTHER parts don't wear first before rings seat. If the holes are round and the surface was right - the rings are broken in in the first couple of times out All that happens is the microscopic high points wear off - like normal. Do the process of breaking in as the ring makers suggested in the 70s and then drive it like you own it. Don't mess around hoping for later break-in. Things will loosen up - but that's wear, not break-in. Don't use a special break-in oil. Those are bunk. The idea is to PREVENT wear and you can't allow wear for one part and prevent it for others. When they say "change the break-in oil at xxx miles" they mean the FIRST oil you put in it, not some special break-in oil. Whatever you are going to use - put that in for the first oil, then change it early to get rid of the metallic content from the microscopic high points wearing off, then fill it again with the same oil you will always used and go like normal. If it's not broken in in the first day or two - it won't be. |

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 1:12pm Posted: Jun/25/2019 at 1:12pm |

The point is to achieve TORSION - to deliberately twist the ring so the bottom edge is forced out. The bevel allows combustion pressures to push the ring out and down and twist it forcing the lower edge out like a scraper. There may be a bevel or even a "rabbet" in the inside of the top - allowing combustion pressure and for the ring to TWIST, lower side out. They want ring twist. In fact in the books I have they say you can tell if a ring was installed up-side-down after only a few miles by looking at the points of contact on the face of the ring. Correct installation the BOTTOM of the ring should show shine from contact, the top not. But if the top half of the face of the ring is shiny it was up-side-down. So you can tell - if the face has shine on the bottom half it's fine, if the FACE of the ring has shine on the upper half, it was put in wrong. They want the lower half to TWIST OUTWARD - and they MAY do that with a bevel or notch, etc. MAY. Here is FACTORY information from DANA/Perfect Circle........ note their instructions in text books of the day........... this information was taught in colleges, high schools, and more for years, perhaps decades. It comes from the factory - their own training program for techs. All rings pictured in correct orientation. If I get a chance I have my college engine books downstairs and can grab those and see what they say as well. Will be interesting to see if they disagree. I also have some NOS rings and such in my shop I can check - I got a set of NOS pistons and rings out there for using in a 343 I am building.      |

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 1:29pm Posted: Jun/25/2019 at 1:29pm |

|

Here is a second source verifying I was correct - another college text book - used in colleges and other schools around the country for how many years......... they seem to agree with my experience over the years, Perfect Circle's info, etc.

(When I saw that "no" in red I cringed but resisted an instant reply - it just flew against my training in school and experience for all these years. I figured I was right and the upper cut or bevel on the inside goes UP but I knew folks would come at me telling me how wrong I was and piling on - so this time I waited to have written proof. It won't matter - I know. ) I can still check the rings I have in my shop to see WHAT STYLE I have, but chances are it will agree with me and this other info from TWO books with factory information. It's science. You want that ring to TWIST, torsion, and combustion pressures, to work on the top inner edge to force the ring to twist and shove it out.  |

|

|

|

farna

Supporter of TheAMCForum

Moderator Lost Dealership Project Joined: Jul/08/2007 Location: South Carolina Status: Offline Points: 19689 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 3:37pm Posted: Jun/25/2019 at 3:37pm |

|

I didn't go into great detail like you did, but pretty much said it needs to get to operating temperature first as you pointed out Bill. Just didn't go into any detail on how to drive that first couple hundred miles (and it may not, really shouldn't, take that long). Rebuilders today pretty much say go out and drive it... but vary the speed, no long steady interstate cruises for the first 200 miles or so. That's what the big engine builder told me who built my 4.0L short block. I didn't have any issues with it, broke in with little smoking. The last engine I assembled everything myself on was my 4.6L stroker back in 2000. I don't recall the type of rings I used, but it took a while to get them seated. They didn't want to seat driving it around town. So I took it on a four hour each way trip 9roughly 200 miles each way). Back roads most of the way, only half the trip was interstate but even that was hilly enough that it's hard to keep a constant speed without cruise control. No cruise and I didn't try to keep a constant speed. When I got to my destination it was still smoking some. Took plugs out and they did look pretty bad... cleaned them. By the time I got back home the engine wasn't smoking, maybe very little. Took plugs out and they were half as bad as they had been, but threw them away and put new in. One engine I had trouble seating the rings in was a 195.6 L-head. I know it was built with chrome rings. That darn thing wouldn't seat! I finally took it out and ran the crap out of it one day, and ran it hot (yes, I mean I boiled the radiator over!) in the process. THEN the rings sealed after I let it cool down and started over!! I don't recommend that... I did it out of frustration and I was young. Now I'd probably disassemble the thing and put in a different set of rings. I think the old 196 just didn't turn enough rpm or get warm enough to seat chrome rings

|

|

|

Frank Swygert

|

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/25/2019 at 3:56pm Posted: Jun/25/2019 at 3:56pm |

|

I put my 4.0 in, took it out and drove it. Period. I did the recommended full-throttle accelerations a few times. Nothing special otherwise - drove it like I owned it, drove it like normal. Hard.

No smoke EVER - not even first few minutes. Just plain NO SMOKE. It has never been down between changes - which I try to do about 3500 or so miles -sometimes up to 5000 miles. I used synthetic in it - pretty much the whole time. I did start with a really good regular oil then changed my mind after 500 mile oil change and decided what the heck - put the best in it. 33,50 miles on it now, never down even as much as half a quart. Never any smoke. Plugs clean. |

|

|

|

Post Reply

|

Page <12345 7> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |