Mandatory oil system mods

Printed From: TheAMCForum.com

Category: The Garage

Forum Name: AMC V8 Engine Repair and Modifications

Forum Description: AMC-made V8 engine mechanical, ignition and fuel from basic repair to high-perf modifications

URL: https://theamcforum.com/forum/forum_posts.asp?TID=98258

Printed Date: Apr/18/2024 at 5:59pm

Software Version: Web Wiz Forums 12.03 - http://www.webwizforums.com

Topic: Mandatory oil system mods

Posted By: Amc wannabe

Subject: Mandatory oil system mods

Date Posted: Jan/24/2019 at 5:32pm

|

i am rebuilding a late 360 to be a performance daily driver. I plan on dabbling in autocross/drag/maybe even road course as well. So I will not be babying it or rarely driving it. With that being the case I have a few questions about the piling system. 1. I have read the lifter valley line may/may not be important. For those who say it isn’t, why not? 2. External oil filter pickup line/road race setups(think milodon) since I expect pushing Gs in several directions, would this be of great importance compared to other mods or only extra insurance? 3. I read somewhere that an issue might be keeping oil in the pan(sounded like drainback issues) if anyone knows about that, please enlighten me. 4. Any other oiling info or suggestions? I would like to have this thing ready and right the first time. Thanks in advance.

|

Replies:

Posted By: mmaher94087

Date Posted: Jan/24/2019 at 5:59pm

|

My opinion: I believe the #1 oiling mod is to weld two 3/4" flat washers, 180 degrees apart to the bottom edge of the oil pan pickup. This prevents the pump from sucking up the pan bottom and stopping the oil flow from the pan to the pump. No washers; use flat bar stock; both are readily available at your hardware store. If your oil pickup has a hole in the top of it; weld that up as well. If your pickup has the nylon spacer plug on the screen side; pull it off and throw it out as it will deteriorate and get sucked into the pump. ------------- Mike |

Posted By: 304-dude

Date Posted: Jan/24/2019 at 6:10pm

|

Agreed on the above reply, it is a simple mod that can save you in the long run. Depending on rebuild for hiperf use, 1 quart more than full on the dipstick marker. FL1-A filter conversion. $9.00 part from Mopar dealer service counter and plug your oil bypass to use the Ford filter built in bypass.you get a fresh bypass with every oil filter change, as the old built in bypasses can stick from years of use, and have been known for the lack of reliability. Double check bearing clearances, cam timing gear oil reliefs, distributor gear clearances, and cam bearing bore for clean groove to feed the front. Not much for mods, but they resolve big issues or troubles if overlooked and ignored. ------------- 71 Javelin SST body 390 69 crank, 70 block & heads NASCAR SB2 rods & pistons 78 Jeep TH400 w/ 2.76 Low 50/50 Ford-AMC Suspension 79 F150 rear & 8.8 axles Ford Racing 3.25 gears & 9" /w Detroit locker |

Posted By: BassBoat

Date Posted: Jan/24/2019 at 9:41pm

|

If your budget can stand the $500 hit for a Canton Street/Road Race oil pan and specific pickup for their pan, I highly recommend it. |

Posted By: mixed up

Date Posted: Jan/24/2019 at 11:38pm

|

on drain back issues I cleaned up and opened up all my drain hole in the heads and in the lifter valley very simple with a carbide rotary file make sure you have proper timing sprockets and alignment of cam gear and extra oil capacity ------------- 69 amx 290 auto 65 220 290 4spd 80 ford fairmont |

Posted By: FSJunkie

Date Posted: Jan/24/2019 at 11:51pm

|

I worked in a shop that built more AMC performance engines than any other and they've never had an engine fail. 1. Proper bearing clearances. 2. Proper oil pump clearances. 3. More than 5 quarts but less than 6 quarts of oil inside the engine. 4. Forget the oil line mods. 5. Use restricted pushrods and polish the return path if you feel drain-back is inadequate. ------------- 1955 Packard 1966 Marlin 1972 Wagoneer 1973 Ambassador 1977 Hornet 1982 Concord D/L 1984 Eagle Limited |

Posted By: WesternRed

Date Posted: Jan/25/2019 at 12:08am

|

I was going to bring up the subject of restricted flow pushrods, certainly worth considering. How hard you want to push it on a road course is probably going to be the biggest factor, sustained high RPM use is what will suck the oil pan dry. I think running down the drag strip in your average street/strip car requires little more than making sure that the factory oil system is working as intended and running an extra quart of oil. Maybe if you are heading into sub 11 second 1/4 mile territory, then you will start having to take this stuff a little more seriously.Autocross, I'd say pretty much as above with the addition of a high capacity road race type oil pan.

------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Amc wannabe

Date Posted: Jan/25/2019 at 4:59am

| thanks guys, great info. This is looking like it will save me a load of money as well. Those milodon external setups alone are near a grand complete. Could I get clarification on what makes that lifter valley oil line unnecessary? We’re people putting too small of lifters in and the oil was bleeding down before it got to the rear? |

Posted By: Rebel Machine

Date Posted: Jan/25/2019 at 6:50am

|

To reduce/eliminate the aeration of the oil at high rpms I modify a Mopar 340 windage tray for use in the AMC V-8. Also use the Canton drag/road race eight quart pan. -Steve-  |

Posted By: 1982AMCConcord

Date Posted: Jan/25/2019 at 6:51am

| Lots of great advice so far.. looking forward to learning more. |

Posted By: WesternRed

Date Posted: Jan/25/2019 at 7:32am

|

Interesting use of the Mopar windage tray, I actually have one of them in my small block Mopar powered BMW that is a dedicated track day car. Other oiling mods on that one are a high volume oil pump and a baffled truck oil pan that holds a bit more oil, so far so good (touch wood) and had been on the track for quite a few years now. I don't think you will ever get a consensus answer on the valley oil line mod, my view is that there is only so much oil to go around in a pressurized system with controlled leakage (i.e. bearing clearances), so adding an extra pipe to the same location isn't going to deliver any more oil and possibly introduce addition points where you can have a failure. You will of course get other opinions on the subject. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Steve_P

Date Posted: Jan/25/2019 at 2:52pm

|

Use an Aviaid, or that style, road race pan. This is the most important item you can possibly do- if you do this you can pretty much forget all the other tips and tricks else less proper assy clearances, quality parts... which you must do anyway. Doing any type of autocross or even light road racing with a stock pan is begging for a spun bearing. |

Posted By: mixed up

Date Posted: Jan/26/2019 at 6:47am

|

the oil line in the valley is a fix for the starvation of oil to the crank and rods in that area if your not looking into sustained high rpm use its really not necessary ------------- 69 amx 290 auto 65 220 290 4spd 80 ford fairmont |

Posted By: amx007

Date Posted: Jan/26/2019 at 8:08am

|

Is that fix for all 3 engines 290 343 390 , the valley oiler ? ------------- dream red white and blue 1968 Chicago auto show amx 290 4 speed 1969 driver Amx 290 auto |

Posted By: jcisworthy

Date Posted: Jan/26/2019 at 8:31am

|

The only thing I can really see the valley oil line doing, is possibly supplying less aerated oil to the rear of the engine under "spirited driving" or racing conditions. That is of course, if the oil moving from the beginning to the end of the lifter gallery actually gets aerated as it passes by the lifters, or aerated enough to make a difference. The oil line would not stop aerated oil to the rear of the engine, but it would introduce non, or less aerated oil into the mix. Now, the rest of the mains and rods would still see more aerated oil if that is indeed happening. There is a large enough hole in the factory oil gallery to support a lot of oil flow around the lifters. That is why I have my doubts concerning the addition of the oil line having any real benefits. As a fix for starvation, I would not think the line would have any real benefits because I do not think starvation is an AMC issue if the oil in the pan does not go below the pickup. The oil factory gallery is narrowed substantially when lifter bushings are installed so that is a case where it probably would be warranted. ------------- Specializing in dyno services, engine building, and cylinder head porting rbjracing.com Phone Number 518-915-3203 |

Posted By: Boris Badanov

Date Posted: Jan/26/2019 at 10:28am

|

The oil system in an AMC v8 is pretty adequate when everything is in top shape. I agree with eliminating the plastic button in the oil pick up. welding or riveting in a spacer is preferred. I have seen a few engines destroyed by that plastic button dislodging cutting off all oil pressure. Eliminating the umbrella valve seals is a BIG improvement. This is another engine killer when they break up and clog the returns. Opening and or polishing the returns in the heads seems like a good idea, but be warned, you can weaken the head bolt boss that is in CLOSE proximity to the passage. More oil in the pan using a Milodon or other pans is a good idea. More oil alone just makes for excessive oil airation. AMC copied one of the worst oil systems ever in a American V8 The Buick... but with the above minor improvements they will be as reliable as any. leave ther internal bypass and external drains to the racers. ------------- Gremlin Dreams |

Posted By: Ken_Parkman

Date Posted: Jan/26/2019 at 10:30am

|

X2. I plumbed oil pressure gauges on both sides of the galley on an engine without the added line for dyno testing. I could measure no significant difference in oil pressure through 7000 rpm. At least on that engine there was absolutely no need. The only reason I can come up with is to maintain oil supply (not pressure) to the rear of the crank if you have valvetrain failure and pitch a lifter. That's a possible reason, but pretty feeble hope. I did have a Ford 460 that broke a rocker and pitched a lifter. It probably drove 20 miles at highway speed with no oil pressure (would have had flow) and did not blow up. Sort of amazed at that one.

It may be a different story on a bushed lifter engine. I think that mod came from a real race application where due to other mods it was a good thing. Not applicable to a stockist engine. |

Posted By: Trader

Date Posted: Jan/26/2019 at 9:43pm

|

I believe John is on the right track for the valley line and spirited driving. But the issue would be aerated oil releasing air in the gallery and forming air pockets. These could move, when formed, to the channel of most flow in the engine when formed. In an AMC V8, from failures experienced, the rear. As pressure drops flow increases in a hydraulic system. The line therefor would not increase either pressure or flow unless a new leak path is introduced as Ken pointed out. It must either provide an alternate path for aerated oil to break into smaller air pockets or displace air pockets at the rear of the gallery. Air would then travel up into the lifters and cause little if any short term problems. Agree, it is not needed for an average street engine. There are other proven oil aeration solutions at the bottom of the engine that performance people are using. |

Posted By: 73hornut

Date Posted: Jan/26/2019 at 10:48pm

|

The only known "madatory" oil system mods, all involve the use of aftermarket timing sets, and needing to mod them just to make them work properly and supply oil to the distributor gears. ------------- 71 Javelin 74 Gremlin 79 Spirit AMX Rogue Valley Rumblers Like Us on FB https://www.facebook.com/groups/1602825606650796" rel="nofollow - https://www.facebook.com/groups/1602825606650796 |

Posted By: JolleyGreenSST

Date Posted: Jan/27/2019 at 1:19am

I just bought a Comp Cams (part# 3118) double roller timing chain for my 401 build... do I need to modify something for it to work properly? https://www.ebay.com/itm/COMP-Cams-Timing-Chain-Gear-Set-Hi-Tech-Double-Roller-Steel-Sprockets-AMC-V8-Set/332795972368?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649" rel="nofollow - https://www.ebay.com/itm/COMP-Cams-Timing-Chain-Gear-Set-Hi-Tech-Double-Roller-Steel-Sprockets-AMC-V8-Set/332795972368?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649 ------------- "God is good all the time and all the time God is good!" |

Posted By: Rebel Machine

Date Posted: Jan/27/2019 at 7:24am

|

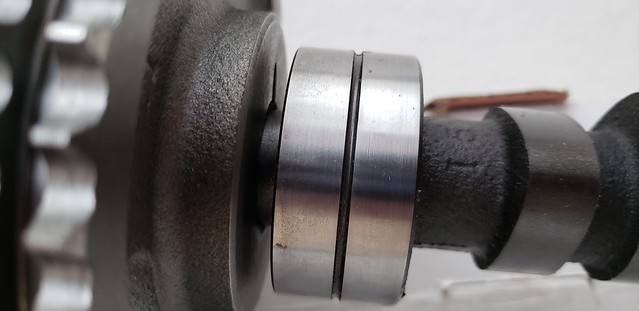

The oiling passage in all the aftermarket cams and timing gears needs

to be checked. The front cam journal supplies a path for oil going to

the distributor drive gear. Many times the timing gear has that groove

in the wrong place or the groove extends beyond the diameter of the

cam's front journal. This is a comparison of an aftermarket cam gear (left) and an original AMC gear (right). You can see the aftermarket gear groove extends well beyond the distance of the original gear. The arrow shows the timing gear groove extending past the cam journal diameter causing a loss in flow going forward to the distributor drive gear. I've welded and machined the timing gear to fix that.

|

Posted By: scotty54

Date Posted: Jan/27/2019 at 8:39am

|

This is the first I have heard of the extra quart. Any issues with the depth of the stock pan and frothing? Do the compacts have a different pan that may preclude the extra quart? I have always done the oiling mods originally recommended by Performance American Style and never had a bearing fail. But it appears that those who don't do the mods haven't had a fail either. Great info in this thread!

|

Posted By: Trader

Date Posted: Jan/27/2019 at 9:07am

|

The extra quart was a thought up patch early on as people thought the problem with the AMC motor was too much oil being pumped to the top of the cylinder heads and that caused the oil pick-up to catch air. Modern thinking and track proven is oil aeration being the big problem, oil frothing in the crankcase and picking up air. The extra quart would actually aerate the oil more as the crankshaft spins through the excess oil. This air/oil mix would then be pumped through the engine and not lubricate near as well as straight oil. Air separation in the top of the engine can cause even more problems if not achieved in the valley or rockers. An extra quart oil pan reduces aeration of the oil and also provides for "spirited" driving as oil is pushed front to back or side to side. The stock pan with stock oil level is good for every day driving.

|

Posted By: PHAT69AMX

Date Posted: Jan/27/2019 at 1:04pm

|

Previous thread with Oiling info and Diagrams: http://theamcforum.com/forum/oil-path-amc-distributor-gear-oiling_topic95506_page1.html?KW=oiling" rel="nofollow - http://theamcforum.com/forum/oil-path-amc-distributor-gear-oiling_topic95506_page1.html?KW=oiling

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: bobsterfl

Date Posted: Jan/27/2019 at 2:03pm

|

Lots of good advice in all these posts. I am old enough to remember AMC being involved in the Trans Am racing series, and have read numerous articles over the years describing blown-up engines due to oiling problems. Of course, these cars were revving high and experiencing really high g-forces in hard cornering. The final ultimate fix was to change over to a dry sump, belt driven external pump with a large external oil tank, very similar to what NASCAR uses today. That would be overkill for most of us. ------------- Bobsterfl 1970 BBO Javelin 390 - Torqueflight |

Posted By: Boris Badanov

Date Posted: Jan/27/2019 at 2:14pm

|

The crank is in the oil at start up and an extra quart exaggerates the issue. Oil return is marginal in an AMC because of small return openings in the heads and the collection of oil in hard acceleration in the lifter gallery area. Stock umbrella seals broke up and the debris blocked the returns and cause general mayhem in the oil system. Yes, I have seen a number of AMC V8s that had oil pressure only until the oil was all pumped to the valve covers. Sludge and umbrella seal debris slowed the return. Wait a few minutes and re-start and oil pressure was back. For a few seconds..... The plastic button on the oil pick-up had a similar effect. The button becomes dislodged and the pick up goes flat against the bottom of the pan. AMC V8 is a great motor when all is well, any motor fails with no lubricant. ------------- Gremlin Dreams |

Posted By: farna

Date Posted: Jan/28/2019 at 6:36am

|

I don't have the supporting documentation any more, and can't remember where I even got it, but the AMC Gen2/3 V-8 was designed for six quarts from the start. Six quarts are specified for police and heavy duty fleet use (taxis and such) -- and they use the SAME OIL PAN STAMPING. The police pan has a rudimentary baffle to keep oil from being sloshed to the front in hard stops, that's the only difference (don't know if the HD/Fleet pan is the same as police or just a standard pan). Marketing cried that a six quart oil change would make AMC engines more costly to maintain than the competition, so it was tested and found that five quarts was sufficient for normal driving, so the owners manuals state five quarts -- same as everybody else in that era. The valley line was introduced by drag racers to help with oil starvation under hard acceleration to the rear main and rod bearings. Basically it just supplies extra volume by having another path. I think it is an aerated oil issue -- the oil gets sloshed hard enough to the rear of the pan and a lot of oil is quickly sucked up out of the pan, allowing a little air to be sucked in at the pickup. The twin paths increase the amount of oil, and should reduce aeration. I don't think it's necessary except on those really quick drag cars -- not your usual weekend bracket racer. You have to be pushing the engine near it's limits to make extreme mods like that, and I mean really built up to near max possible output. Building a 10 second or less 1/4 mile car? You might need it. ------------- Frank Swygert |

Posted By: Rebel327

Date Posted: Jan/28/2019 at 6:59am

|

I believe someone posted pic of the 6th quart in pan. Considering the extra volumn and the additional minimal depth of oil as it is spread about the surface area...aeration is not an issue. The extra volumn creates no harm but instead provides several benefits. Wish I could remember who posted pic. I think he has built over 100 AMC V-8's.. |

Posted By: Trader

Date Posted: Jan/28/2019 at 12:52pm

|

I have made all my oil pans 6 Quarts since 2012 but have not built 100's of engines. I remove the standard pan baffle, hammer and dolly the back of the pan to an outy and not an inny and re-install the standard baffle.   Next pan to do:  |

Posted By: Red Devil

Date Posted: Jan/28/2019 at 1:11pm

|

Deja-vu ... check a few posts down for more discussion on pans & capacity. http://theamcforum.com/forum/amc-v8-police-oil-pan-variant_topic97910_page1.html" rel="nofollow - http://theamcforum.com/forum/amc-v8-police-oil-pan-variant_topic97910_page1.html Quotes from that thread posted by Steve P, an actual Engineer who worked at AMC:

X2 his post in this thread to fit an Aviaid pan or similar. I've got an Armando pan on my 401 (very similar to the Aviaid as Armando used to work for them). http://aroilpans.com/Roadrace.html" rel="nofollow - http://aroilpans.com/Roadrace.html http://aroilpans.com/images/AMC_2.jpg" rel="nofollow - http://aroilpans.com/images/AMC_2.jpg Hope this helps,RD

|

Posted By: JolleyGreenSST

Date Posted: Jan/28/2019 at 2:57pm

Thanks for the reply Rebel Machine! I just checked my new summit camshaft and comp cams timing gear, it seems to be covered enough that I shouldn't have any problems. but hear are some pics to get your opinion... https://flic.kr/p/2etdsoP" rel="nofollow">  https://flic.kr/p/2etdsoP" rel="nofollow - AMC cam and timing gear passage clearances. by https://www.flickr.com/photos/163232977@N08/" rel="nofollow - David Cruz , on Flickr https://flic.kr/p/2etdsoP" rel="nofollow - AMC cam and timing gear passage clearances. by https://www.flickr.com/photos/163232977@N08/" rel="nofollow - David Cruz , on Flickr https://flic.kr/p/Sk7cyJ" rel="nofollow">  https://flic.kr/p/Sk7cyJ" rel="nofollow - AMC cam and timing gear passage clearances. by https://www.flickr.com/photos/163232977@N08/" rel="nofollow - David Cruz , on Flickr https://flic.kr/p/Sk7cyJ" rel="nofollow - AMC cam and timing gear passage clearances. by https://www.flickr.com/photos/163232977@N08/" rel="nofollow - David Cruz , on Flickr------------- "God is good all the time and all the time God is good!" |

Posted By: 73hornut

Date Posted: Jan/28/2019 at 6:19pm

|

Make sure the slot also lines up with the oil hole in the cam. ------------- 71 Javelin 74 Gremlin 79 Spirit AMX Rogue Valley Rumblers Like Us on FB https://www.facebook.com/groups/1602825606650796" rel="nofollow - https://www.facebook.com/groups/1602825606650796 |

Posted By: Rebel Machine

Date Posted: Jan/28/2019 at 6:21pm

-Steve- |

Posted By: JolleyGreenSST

Date Posted: Jan/28/2019 at 7:03pm

|

Thanks Steve. And yes I lined up the slot with the oil hole or whatever it is called. @73hornut David.

------------- "God is good all the time and all the time God is good!" |

Posted By: PHAT69AMX

Date Posted: Jan/28/2019 at 8:11pm

|

Previous thread with Cam Snout Stack Oiling Drawing and info: http://theamcforum.com/forum/oil-path-amc-distributor-gear-oiling_topic95506_page1.html?KW=oiling" rel="nofollow - http://theamcforum.com/forum/oil-path-amc-distributor-gear-oiling_topic95506_page1.html?KW=oiling revised 09-04-19 - "opinions" added, drain-back. Lifter Orifice revised 08-28-19 - add above link revised 02-07-19 revised 02-17-19 revised 04-21-19 revised 07-30-19 Just a middle aged hobbyist Hot Rodder guy. Had a '69 AMX from 1985 to 2014. Paid shop to do 1st motor rebuild. Self-assembled the next three. Web active since about 1995. Not my ideas, those of many others. Collected many little "Oil" things that can be done. Mandatory? Doubtful. Helpful? Maybe. In no way an endorsement, just a compilation. Quite a bit here really once all typed up. Sure there are more, will edit / add as needed. Kinda 2 categories: - Do things to what is already there - Add, change, replace things AMC V8 Oil System Checks and Modifications Debated for Decades: - Extra Lifter Valley Oil Line, considered "Preference" - Alternative, ? same but different ?, a 180 degree piece of steel line plumbed between the (2) 3/8 pipe Plugs in the Lifter Oil Galleys on the back side of the Block. Requires a small block rib clearance notch for steel tube. Obvious: _ AMC Oil Pump has -NO PROBLEM- with Volume (Pump Gear Length) * Must Keep SUMP FULL *, "Pan", so Drainback... - Cam, Crank, & Rod Bearing Clearances to AMC SPEC - Pick-Up to Pan Clearance to Spec - Oil Pick-Up Head to Pan Stock PLASTIC Spacer, Secure in place or Replace with 1/4" Bolt or equivalent Oil Pump: - Aug 2019 - has been reported MISSING "Vent" HOLE(s) in Pump Cover Gaskets - Deburr New Pump Gears and SHAFT SLOT to prevent any damage to shaft hole in Timing Cover - Temporary Assemble New Oil Pump Gear and Actual Distributor that will be used for Final Assembly w/o Drive Gear to Confirm NO BINDING between Pump Gear Shaft Slot & Distributor Shaft Drive Blade - "Parkman Mod" ? at bottom of Pump Gear Pocket for "anti-surge" - enlarge / port match Round Outlet Hole in pump cavity pocket - use late angled cover rather than early 90 cover - block off filter bypass, or new cover with out - change threaded filter Adapter for one that fits larger later filter - inspect Pressure Relief Plunger Passage for finish and size - soften / blend oil passage intersection corners where possible - ? there is a Mod that moves Bypass Plunger Bleed Oil passage or something - ? "Do" the AMC V8 Oil Pump Pressure Relief Bypass Plunger Circuit Vent Modification, see pictures further down in this thread... - ? Fabricate an Adjustable Spring Tension Oil Pressure ByPass Plunger Cavity "Cap" OIL PAN: - ? Run approx 1 extra Quart, more than 5, less than 6 - ? Aftermarket larger Aviad oil pan, but significant cost - ? Crank Scraper / Windage Tray Block: - port match Block Front Ports to Gasket / Timing Cover - confirm / clean drilled passage from pump up to top center oil galley - blend / soften internal oil galley intersection corners where possible - 3/8 Pipe Plug - SHALLOW, Pass Side Front of Block - confirm full drill through Main Saddles up to Lifter Galley - inspect oil pan rail suction passage - Pick-Up, confirm no galley obstruction once screwed into pan rail - ? add ~1/8 oil drain holes in lifter valley, or others ? - ? Chamfer / Blend 2 Front Oil Drain Holes ? - ? Restrictor ? Font of Drivers Side Lifter Oil Galley Passage Behind external visible Driver's Side 3/8 Pipe Plug, Tap Block & Install 2nd Pipe Plug with small drilled Hole - ? Added external Oil Line & Fittings, back of Block, connecting the two Lifter Oil Galley passages that are Plugged Stock - ? "Drastic" somehow Drill DRIVER SIDE Lifter Oil Galley to Oil CAM BEARINGS from that side and install Cam Bearings with Oil Hole on the Drivers Side. Then MAINS are Passenger Side Oiled and Cam from Drivers. - ? "Drastic" BEHIND the Block Front Drivers Side 3/8 Pipe Plug for the Lifter Galley, Tap the INTERNAL Lifter Galley Hole for a Pipe Plug drilled with a "small hole" ? size ? to restrict Oil Flow to the Drivers Side Lifters and "increase" Passenger Side Lifter, Cam, and Main Oiling - Rear Main Bearing ? Brg Clearance Different than other Main Bearings ? Rear Main Seal Knurled Surface ? ? Sealant Longways along Outer Brg Cap to Block Axial Corners - ? 401 AMC Cranks ONLY ? ? #4 Main Main Brg to #5-6 Rod Brg ? OIL PASSAGE *Clocked Location* "incorrect" Different Clocked Location than ALL OTHER AMC Cranks... - "Drastic": External Oil Pump Suction Line required: Added Internal Oil Line from stock Pick-Up Hole ( now an Oil Feed ) to drill and tapped hole in top of #4 Main Bearing Cap Ref: Above 401 Crank Main #4 Oil Passage Drill Location Drainback: OPINION - ONE OF, IF NOT "THE", MOST SIGNIFICANT AREA OF ATTENTION. - deburr / blend lifter valley drain back corners - inspect / blend / ? enlarge ? cylinder head drain back holes - ? Drill additional Drain HOLES in Block Lifter Valley ? Hole Size, Location, and Quantity varies - ? Modify bottom of Timing Cover at Front Bearing Cap "gap" area - ? Traco Mod, ~1/4" Holes drilled through in Cyl Heads between Pushrod Holes *DRAIN OIL* Pumped Up On Top of HEADS - "Drastic", Tapped holes in ends of Heads above level of valve train "floor" but below Valve Cover Gasket Surface & Install/Run 2 or more AN Oil Drainback Lines/Hoses to Oil Pan "Effectively" Drain "Excess" Oil from Top of HEADS to Oil Pan Heads: OPINION - LIFTER OIL PASSED VOLUME MUST BE "BALANCED" WITH MEAGER DRAIN-BACK PASSAGES. - No umbrella seals, machine valve guides for Perfect Circle Valve Stem Seals Obviously, ensure removal of all disintegrated Umbrella Seal pieces from all areas of engine and parts Cam: - Correct Cam Bearing Installation Oil Hole Size & Location - confirm front snout stack-up oil passages - Cam Sprocket, ? Front Face Slinger Grooves, size and quantity ? - Full Groove front most bearing and/or journal - bleed hole rear most bearing journal - Rear Freeze Plug installed depth Lifters: OPINION - LIFTER INTERNAL OIL METERING DISC RESTRICTOR ORIFICE SIZE IS "CRITICAL" TO PREVENT EXCESSIVE OIL BEING PUMPED UP TO THE HEADS WHICH HAVE MEAGER DRAIN-BACK PASSAGES, CAN FILL WITH OIL AT RPM, AND STARVE THE OIL PAN PICK-UP CAUSING IT TO SUCK AIR. Just what the "correct" Metering Disc Orifice Size is, is yet to be determined. - ? Correct FIT Lifter to Bore, .904 Lifter OD and Lifter Bore ID Lifter OD = .9040"-.9045", Tappet Bore Clearance = .0010"-.0025" 1975 AMC TSM Lifter & Bore Specs - ? Lifter internal design, oil volume passed * LIMIT OIL Pumped Up on Top of Heads... - ? Restrictor Push Rods Rods: - ? Bearing Oil Squirter Notch at Rod / Cap Joint

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: Jmerican

Date Posted: Jan/29/2019 at 12:25pm

| yes, this guy. ^ |

Posted By: wheelz

Date Posted: Jan/31/2019 at 6:26pm

| Volume is a larger factor in AMC V8s than pressure. My mods are always to increase and smooth the size of the housing and adapter passages and run external filter lines and a deep Pan to increase volume of the system overall with of course careful attention to crank bearing and adapter clearances but I do no internal oil line mods. . The only real mod I do is to have a small line from the sending unit port to the timing cover to lube the dizzy gear for insurance.My most recent build yielded 65 psi at cold start. On the street I change the relief spring to one I cut a couple coils off and have 50 psi to take some pressure off the gears. I do run restricted smith bros pushrods and edm lifters on a mechanical cam as well. Still have too much oil in the heads but that's not a bad thing with $400 comp cam ultra magnum rockers |

Posted By: wheelz

Date Posted: Feb/07/2019 at 4:47pm

|

I have also used this to adjust oil pressure if there is too much after a new build before starting  |

Posted By: 73hornut

Date Posted: Feb/07/2019 at 10:47pm

------------- 71 Javelin 74 Gremlin 79 Spirit AMX Rogue Valley Rumblers Like Us on FB https://www.facebook.com/groups/1602825606650796" rel="nofollow - https://www.facebook.com/groups/1602825606650796 |

Posted By: 69 ambassador 390

Date Posted: Feb/07/2019 at 11:06pm

Um, Not! The extra quart is still below the baffle in the stock pan. The oil level is far below the baffle in a running engine and at no time is the crankshaft spinning in the sump oil. A full quart or more is trapped in each cylinder head and another in the lifter galley during higher speeds. This leaves only two in the pan. I have run many engines on my start stand and sometimes use slotted valve covers during valve adjustments on running engines. The oil level during 2000 rpm cam break in is usually an inch or so in the heads and much more at higher speeds. I have NEVER witnessed any foamed oil in the heads of a running engine. But this is with just limited AMC experience. I've only built about a hundred! ------------- Steve Brown Algonac, Mi. 69 Ambassador sst 390 84 Grand Wagoneer 69 Cougar XR7 65 Fairlaine 500XL 79 F-350 Super Camper Special |

Posted By: JolleyGreenSST

Date Posted: Feb/08/2019 at 2:20am

Sounds right to me and I trust hands on experience over theory any day. So my question is would you think its better to run a higher capacity pan or is it fine to just run six quarts of oil in the stock pan? ------------- "God is good all the time and all the time God is good!" |

Posted By: wheelz

Date Posted: Feb/08/2019 at 6:05am

T/A performance. Its a Buick part and the bolt is a different size so I transfer the adjuster to an AMC bolt by drilling the same size hole and using an AMC spring

|

Posted By: farna

Date Posted: Feb/08/2019 at 6:11am

|

Trader has a few things correct -- aeration/frothing of the oil is bad, the extra quart allows more "spirited" driving, and the stock pan with stock oil level is good for everyday driving. 69 ambassador 390 has the reasons the extra quart works correct, and is also correct that even on startup with all oil drained in the pan six quarts won't contact the crank, at least with the car near level. I suppose it might if on much of an incline, but even then only for a second or two until the pump sucks it up into the engine -- by the time the engine fires it's sucked up half the oil. For regular racing a high capacity pan may make sense. For the occasional trip down the strip or autocrossing the extra quart has proven to be more than adequate. I'd only invest in a high capacity pan with a "floating" pickup only on a high dollar race engine (or any high dollar build). Well, $5K is "high dollar" to me, but what I mean is those $10K+ engine builds. $5K gets you what, a mild but well built engine -- at least if you have a good shop build it. Plenty people on here could build a healthy street/strip engine for $5K or less. Really depends on what you start with and just how "healthy" you want it. And how good/licky at parts scrounging you are. I think I could build one (assuming I started with an engine in decent condition) with all new parts for $5K easy enough. ------------- Frank Swygert |

Posted By: 73hornut

Date Posted: Feb/08/2019 at 7:59am

------------- 71 Javelin 74 Gremlin 79 Spirit AMX Rogue Valley Rumblers Like Us on FB https://www.facebook.com/groups/1602825606650796" rel="nofollow - https://www.facebook.com/groups/1602825606650796 |

Posted By: Red Devil

Date Posted: Feb/08/2019 at 8:49am

... if the engine has sucked up half the oil shortly after it's fired, not surprising we have never ending oiling issue threads :) Also, remember that the engine is angled down approx. 3 degrees in the chassis, so when doing the "extra quart" test, make sure the pan is at a 3 degree down angle to simulate start up. Then if half the oil is sucked out of the pan shortly after start up, lower the level by half then angle the pan 30 - 45 degrees forward, rearward and side-to-side to simulate braking / acceleration / cornering oil levels (45 degrees being 1-g load) ... and check if the pickup is generously submerged in oil under all conditions. Then consider your application and whether the stock pan with 5 quarts or 6 quarts is enough. Hope this helps, RD.

|

Posted By: Trader

Date Posted: Feb/08/2019 at 9:11am

|

Just a little light reading: https://pdfs.semanticscholar.org/0270/899b3d94e43389f53d451e4fb00cfe32e5c4.pdf" rel="nofollow - https://pdfs.semanticscholar.org/0270/899b3d94e43389f53d451e4fb00cfe32e5c4.pdf I find figure 1-5 and connecting rod lubrication interesting as it seems to me a plausible cause for #6 failures and typical AMC failures towards the rear due to "bubbles forming and blocking oil flow. |

Posted By: Shawn_Watson

Date Posted: Feb/08/2019 at 9:25am

|

You're definitely going to have aeration issues if the "fix" for poor drainback is more oil, at least in my opinion. Shawn |

Posted By: Trader

Date Posted: Feb/08/2019 at 10:00am

|

Typically on most engines, 1 to 2 quarts of oil are in motion above the oil pan. Adding one quart would likely be fine if on an AMC this still keeps the crankshaft from aggressively aerating the oil. As RD pointed out the aggressive driving is another matter. On deceleration the "police pan", you would think, without the "standard pan" baffle, move so much oil to the front of the engine that you would aerated heavily but also expose the oil pickup to air. I'm not convinced the "police pan" is a desirable thing to have. Just reading on the g forces, a stock 1970 Go Pack AMC by the numbers (time/distance) would pull 0.4g on acceleration and with disk brakes was best in class and pull 0.6g braking. Not bad for a 1970 vehicle, as a BMW M3 today is best in class pulling 1g (32 ft/s-sq) braking.

|

Posted By: Sonic Silver

Date Posted: Feb/08/2019 at 10:58am

|

Posted By: wheelz

Date Posted: Feb/08/2019 at 12:00pm

|

Adding a remote oil filter will also add capacity to the system. I like to run the Bulltear adapter and braided lines to the filter adapter. Along with my 8 qt Milodon I have almost 10 quarts but I only put in 9 so I have 7 in the pan |

Posted By: White70JavelinSST

Date Posted: Feb/08/2019 at 12:08pm

Here's the link you were asking about http://www.taperformance.com/proddetail.asp?prod=TA%5F1502" rel="nofollow - http://www.taperformance.com/proddetail.asp?prod=TA%5F1502 looks like they cost about $20 I was wondering, cause T/A Performance sells oil pump gears for Buicks, if the Buick gears are a bit larger than AMC gears, and if so, could the oil pump housing on an AMC timing cover be bored to fit these larger gears, thus making all those used housing with grooves in the oil pump bores, much more re-useable? ------------- 70 Javelin SST, second owner, purchased 1972 |

Posted By: 73hornut

Date Posted: Feb/09/2019 at 12:27pm

------------- 71 Javelin 74 Gremlin 79 Spirit AMX Rogue Valley Rumblers Like Us on FB https://www.facebook.com/groups/1602825606650796" rel="nofollow - https://www.facebook.com/groups/1602825606650796 |

Posted By: PHAT69AMX

Date Posted: Feb/09/2019 at 6:25pm

AMC Oil Pump Gears are already Longer and deliver more Volume than Buick Oil Pump Gears.

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: White70JavelinSST

Date Posted: Feb/11/2019 at 12:17pm

|

Yeah, I was kinda excited at first, but of course larger gear diameter means different shaft spacing, should thought of that myself. Too much wishful thinking.... ------------- 70 Javelin SST, second owner, purchased 1972 |

Posted By: PHAT69AMX

Date Posted: Feb/17/2019 at 1:29pm

|

Revised long AMC Oil System "info" List on Page 4

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: ChillyB

Date Posted: Mar/12/2019 at 2:49pm

|

Regarding filter bypass, and after a fair amount of reading on this forum and others, I've concluded there is no reason to retain the factory bypass in the filter housing. But now I'm down to two options: 1. Run 100% filtration. Not sure I'm there yet. Yes, the housing bypass was eliminated with late engines because it was unreliable. But did they concurrently switch to a filter with integral bypass? If so how did the filter's integral bypass pressure compare to the one eliminated from the housing? Maybe the same. Lots of modern filter have an integral bypass that opens at single-digit psid. Hardly any modern filters open at pressures less than 20 psid. But this is differential pressure, not absolute pressure. So if your gauge reads 60 psi you may still only have 5 psid across the filter bypass valve (so still closed). 2. Eliminate the housing bypass, use a modern filter with integral bypass. Which filter should I choose? What bypass psid is best? Unless I'm using a high volume pump (I'm not), or starting with a filter that is restrictive when new (I hope not) then I dont think it matters much. If your filter differential pressure increases significantly then your bearings already lost the battle. Effectively maintaining oil flow while collecting all of the bearing bronze and lead probably isnt a winning strategy. The important thing (my opinion) is that you KNOW your bypass hasnt been blocked open by chunk of rogue RTV for the last three oil changes. Unless your engine is shedding massive bits of itself a little bypassing here and there wont hurt anything. 3. Here's what I think I'll actually do. Block the bypass in the housing. For initial break-in, and for a series of rapid succession filter changes (like four in the first day) I'll run filters with NO internal bypass so I provide maximum flow of 100% filtered oil because my engine WILL be shedding bits of break-in debris. After that I'll switch to a high quality filter with internal bypass.Perhaps I'll compare my measured pressure at the gage for each style of filter so see if it seems like my filter is bypassing at high RPMs. |

Posted By: PHAT69AMX

Date Posted: Mar/13/2019 at 10:52am

|

No longer having anything myself to build I'm unsure just what I'd do. But after reading a Smokey Yunik article in a 1980 Hot Rod Magazine I'd probably look into a remote oil filter mounting with 2 filters to reduce oil flow restriction / back pressure through the filter(s). An I'm unclear on what Filter the "new" late model Mopar Filter Fitting fits... The "new" double threaded piece that the filter screws to. -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: White70JavelinSST

Date Posted: Mar/13/2019 at 2:23pm

|

The Mopar adapter fits the Motorcraft FL-1A filter and others as well, anything that matches to the FL-1A. ------------- 70 Javelin SST, second owner, purchased 1972 |

Posted By: Jmerican

Date Posted: Mar/13/2019 at 2:46pm

| there ya go. Ford filter. Built in bypass. Big capacity. I like the Royal Purple. Good media, thick can. Purple. Can’t help that. |

Posted By: farna

Date Posted: Mar/14/2019 at 4:43am

|

Sure you can... just a little spray paint... ------------- Frank Swygert |

Posted By: Trader

Date Posted: Mar/14/2019 at 6:22am

|

Someone at AMO was making AMC decals on there home printer to make stick on sleeves for their oil filters. Nice touch!

|

Posted By: Trader

Date Posted: Apr/21/2019 at 8:52pm

|

I don't see this one in the thread, and have forgotten about it until I was at one today. AMC V8's used several different oil pan pick ups. The one on the left is good as it is 0.050" heavier tube, better concave internal screen, no hole on top, but the extension if not removed actually goes into the block oil passage and cuts off 1/8" or more of the pickup passage.

This is 1970 and 1971 as far as I can determine. The round piece you see is 1/4" brass rod that I have brazed to the bottom and removed the nylon button.  |

Posted By: PHAT69AMX

Date Posted: Jul/22/2019 at 2:14am

|

Not intentionally double posting... but thought it belonged or should be in both places / threads... in their Troubleshooting Techniques area... "Modifying AMC oiling for performance" hmm.., any of you all seen this already ? https://www.holley.com/support/troubleshooting_techniques/#AMCModify" rel="nofollow - https://www.holley.com/support/troubleshooting_techniques/#AMCModify

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: PHAT69AMX

Date Posted: Jul/30/2019 at 12:06am

|

Thought I would add this. These are NOT my pictures or my modification, and I fail to remember where I saved these from, so I am unable to give credit where credit is do, or otherwise. No endorsement, just something I have saved from somewhere from who knows how long ago about making a Modification to the AMC V8 Oil Pump Pressure Relief Bypass Plunger Circuit Vent... edit - Forum Member Red Devil authored the below Pictures and Oil Pressure Relief Vent Modification.  -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: PHAT69AMX

Date Posted: Dec/08/2019 at 4:15pm

|

Relevant historical info about the AMC V8 and OILING or the Oil System performance from the 1969 Car Craft Magazine 4-part Article 'AM Si, Junkee No!' about where Car Craft and Vic Edelbrock built their own 'clone' 1969 Hurst Super Stock AMX 390 car, motor and all. "One other problem we had noticed was a lack of oil to the rocker arms. An examination of the solid lifters showed a flutter valve underneath the lifter button that meters oil through a small .050 hole. From here the oil travels through an .080 hole in the button to the tubular pushrods, and feeds the rocker arms. We removed the flutter valve from the lifter, hoping this would allow additional oil to the topside, only to find out that this wasn't the hot set up either." "caption 3 - Oiling problems with the lifters was one of the puzzles that Vic Edelbrock ( left ) and Bobby Meeks had to solve during testing." "With everything set back together, the engine was re-fired, and during the next few minutes Vic, Bobby, Murray, and myself kept watchful eyes on the many dyno gauges, especially the one measuring oil pressure. With all systems green, Vic preset the Heenan & Froode dyno at 4000 rpm, and pulled the throttle wide open. The power started to come on strong when suddenly the oil pressure took another nose dive. Vic cut the throttle, and we all looked at each other totally dismayed. A thorough checkout showed everything in working order, so we tried another power run. Same results. After five or six seconds of full power the oil pressure would go away. As soon as the power was shut down the second time, I pulled the dipstick to check the oil supply. My suspicions were confirmed, as the stick was bone dry. ( ! An 8-Quart Aviaid Oil Pan ! ) Our lifter modification was working too well. We were pumping oil topside faster than what it could drain back into the pan. After a few seconds at full power, the sump would drain itself to the point where the pick up would suck air, and whammy - no oil pressure. Oh well, back to the drawing boards ! This time we tried a happy medium ( median ) to determine the amount of oil needed topside. The flutter valve was replaced in the lifters, but the .050 metering hole was enlarged to .063 which solved the problem." -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

73hornut wrote:

73hornut wrote: