OIL PATH AMC DISTRIBUTOR GEAR OILING

Printed From: TheAMCForum.com

Category: The Garage

Forum Name: AMC V8 Engine Repair and Modifications

Forum Description: AMC-made V8 engine mechanical, ignition and fuel from basic repair to high-perf modifications

URL: https://theamcforum.com/forum/forum_posts.asp?TID=95506

Printed Date: Apr/19/2024 at 11:07pm

Software Version: Web Wiz Forums 12.03 - http://www.webwizforums.com

Topic: OIL PATH AMC DISTRIBUTOR GEAR OILING

Posted By: PHAT69AMX

Subject: OIL PATH AMC DISTRIBUTOR GEAR OILING

Date Posted: Jul/25/2018 at 10:58pm

|

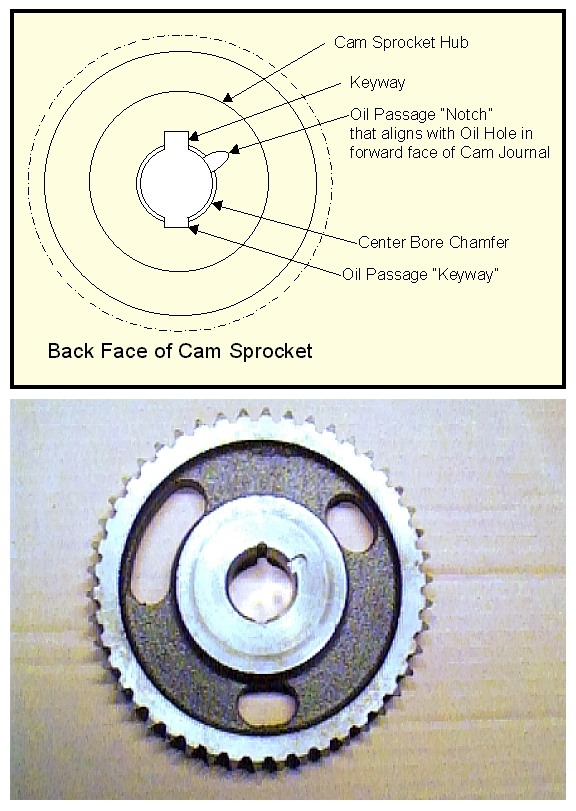

Something I'm working on, decades of discussions, part pictures, and descriptions, but think I have yet to see a section view line drawing showing the AMC V8 DISTRIBUTOR DRIVE GEAR OILING OIL FLOW PATH... The apparent "Achilles Heel" of successful aftermarket AMC Part Manufacturing and Fitment... Sure do miss having working 3D AutoCad software... 07-31-18 Drawing Updated R-4 - Add Rear Cam Journal Oil Vent Hole, etc 09-03-18 Dwg Updated R-5 - Show "non-stock" Sprocket Front Groove(s) Oil. Feedback appreciated... Rev-5 Version 09-04-18  1st Version 07-26-18  Line Drawing & picture showing OIL NOTCH in back of TIMING GEAR  Here is a very good VIDEO graciously made with considerable effort by 401MATCOUPE which presents a clear visual of the oiling and the "questionable" (non-stock apparently) Grooves in the Front Face of aftermarket Cam Mounted Timing Chain Sprockets. Video also mentions the importance of the Crank Oil Slinger (crank oil shedding). Visible Oil flow volume may indirectly "support" reasoning for Drain Back Modifications that can be done to the inside of the Timing Chain Cover "Ridge" and/or the Front Crank Main Bearing Cap (increased drain back clearance gap): Add - Overall AMC Block Oil Circuit Diagram:  -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Replies:

Posted By: FSJunkie

Date Posted: Jul/26/2018 at 2:05am

|

Nice of them to have that method of positive gear lubrication. Many engines just hope that enough oil gets splashed on the gears to keep them happy. AMC thought ahead on this one. ------------- 1955 Packard 1966 Marlin 1972 Wagoneer 1973 Ambassador 1977 Hornet 1982 Concord D/L 1984 Eagle Limited |

Posted By: Rebel Machine

Date Posted: Jul/26/2018 at 6:18am

|

Nice illustration! Don't forget the oiling grooves in the timing gear that sprays oil between the timing gear and fuel pump eccentric. -Steve-

|

Posted By: amx600rr

Date Posted: Jul/26/2018 at 6:33pm

|

That Looks Great! Only minor point is the "Start point in the Cam Journal is "Up" around the 11 oclock position (when keyway at 12 oclock) when the oil passage in the Timing gear is at 6 oclock You show it at 6 oclock on the cam journal. The flow looks dead on. (And thank you for leaving out the "slinger grooves" that are stealing the oil volume and causing the problem) jerry |

Posted By: SC397

Date Posted: Jul/26/2018 at 8:32pm

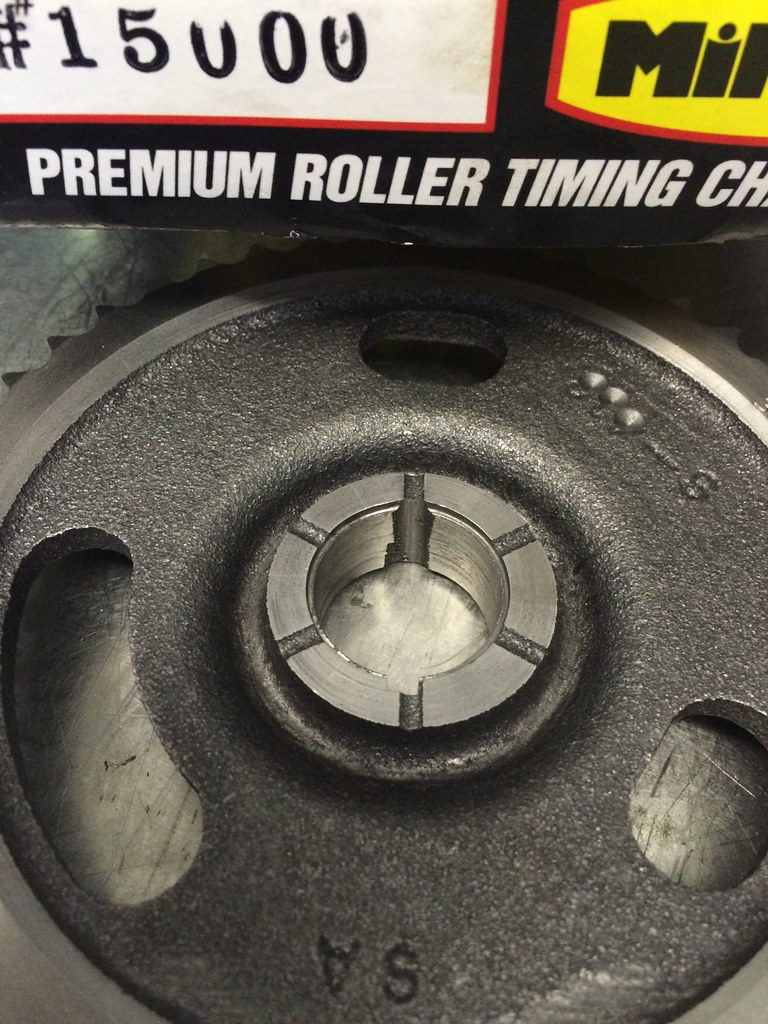

Yea, these slots that I braze shut. The worst one is right at the transfer slot. https://flic.kr/p/JnKVZJ" rel="nofollow">  https://flic.kr/p/JnKVZJ" rel="nofollow - IMG_4417 by https://www.flickr.com/photos/149168736@N07/" rel="nofollow - Rick Jones , on Flickr https://flic.kr/p/JnKVZJ" rel="nofollow - IMG_4417 by https://www.flickr.com/photos/149168736@N07/" rel="nofollow - Rick Jones , on Flickr https://flic.kr/p/JnKW1W" rel="nofollow">

https://flic.kr/p/JnKW1W" rel="nofollow - IMG_4420 by https://www.flickr.com/photos/149168736@N07/" rel="nofollow - Rick Jones , on Flickr https://flic.kr/p/JnKW1W" rel="nofollow - IMG_4420 by https://www.flickr.com/photos/149168736@N07/" rel="nofollow - Rick Jones , on Flickr |

Posted By: Rebel Machine

Date Posted: Jul/27/2018 at 6:21am

|

I modify them as well. I weld them up, have it machined flat then put two shallow grooves in away from the keyway and oiling feed areas. -Steve-  |

Posted By: PHAT69AMX

Date Posted: Jul/27/2018 at 8:54pm

|

Could someone be so kind to post a Picture of the Front Side of a known STOCK 1969 AMC V8 Cam Timing Chain Sprocket / Gear? Thanks for the comments, working on revising the drawing. Considered showing the front Timing Gear "oil slinging grooves" but... wanted to avoid "clutter" and show only Distributor Gear Oiling Path and I fail to remember seeing those Grooves in stock OEM AMC Timing Gears but no longer have old used stock parts on hand for reference or pictures.

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: SC397

Date Posted: Jul/27/2018 at 10:06pm

It is the bottom one with no notches and missing nylon teeth. http://theamcforum.com/forum/timing-chain-gears-question_topic67102_page1.html This is the factory heavy duty one that didn't have nylon gears.  |

Posted By: PHAT69AMX

Date Posted: Jul/27/2018 at 10:20pm

|

Thanks! So Stock OEM had no "slinger slots"... but the Heavy Duty did... hmmm... -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: SC397

Date Posted: Jul/27/2018 at 10:38pm

| Yes but, they were very small. The after market slots are way too big. The True Roller brand changed and now they have way to big of slots too. |

Posted By: PHAT69AMX

Date Posted: Jul/28/2018 at 4:48pm

|

Drawing tweaked, revised, per comments, and added to original Post.

Revised drawing also posted here since page 2... Never fails, revised 2nd time, added 360 deg Oil Groove in #1 Cam Journal. Again, Rev-3, 360 Oil Groove can be in EITHER #1 Cam Bearing and/or Journal... 07-31-18 Rev-4, Only 2 Keys, Add Rear Cam Journal Oil Vent Hole, etc. Rev-4 Version:  -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: amx600rr

Date Posted: Jul/28/2018 at 10:11pm

| Great job!!! |

Posted By: Dave Z

Date Posted: Jul/29/2018 at 6:40am

|

Can this be made to be a "sticky"? Dave Z |

Posted By: PHAT69AMX

Date Posted: Jul/29/2018 at 1:06pm

|

Thanks all, added very good VIDEO made by 401MATCOUPE to the original Post and still tweaking drawing.

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: amx600rr

Date Posted: Jul/29/2018 at 6:30pm

|

Can you believe how much oil is being dumped/lost at the cam timing gear in that video! It looks like an open faucet..... |

Posted By: Rebel Machine

Date Posted: Jul/29/2018 at 6:46pm

|

Are there really three woodruff keys? I remember only two. -Steve-

|

Posted By: PHAT69AMX

Date Posted: Jul/29/2018 at 10:40pm

|

Rebel Machine... Ah ha!, you are Correct afaik... Just fail to recall how 2 keys hold 3 pieces!...

Yes!... Yikes!... Those Timing Chain Sprockets Grooves are hemorrhaging Oil!... Oil Pump moves only a certain volume of oil, pressure results from volume vs loss... -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: PHAT69AMX

Date Posted: Jul/30/2018 at 1:46pm

|

The "other side of the coin"...

Guess while we're at it, this also impacts Distributor Drive Gears. Correct interface between Distributor Shaft and Oil Pump Gear Shaft... Wish I still had some known factory original parts to measure... Wonder if Matt at BullTear has any original AMC Engineering Drawings of this area? An AMC rebuild will replace Oil Pump Gears and often the Distributor. Resulting in the mating of two new aftermarket non-stock items with possibilities of incorrect dimensions and/or fit or interference in the below circled areas. Compounded even further when the Timing Chain Cover is replaced. Square Corners can run up against radius of machining preventing proper engagement. Causing Oil Pump, Distributor, and Distributor Drive Gear problems... And... this interface is "hidden" once the Distributor Drive Gear is installed on the shaft! All new parts must be on-hand and trial assembled well before doing final assembly. Your all's thoughts?  -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: PHAT69AMX

Date Posted: Jul/31/2018 at 11:10am

|

Drawing Revised -4, Only 2 Keys, Add Rear Cam Journal Oil Vent Hole, etc. -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: MacGyver

Date Posted: Jul/31/2018 at 7:18pm

|

I'd really like to see 401MATCOUPE's video, but all I get is a red X... Am I missing a plug-in or piece of software to view it?? (Sorry.. Not very computer savvy...) Or is it viewable on another site somewhere?? |

Posted By: PHAT69AMX

Date Posted: Jul/31/2018 at 11:36pm

|

YouTube, search "AMC V8 Cam Timing/Distributor Gear Oiling" by Kenny Peterson Feb 21, 2015 https://www.youtube.com/watch?v=6QELbRRnEJs -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: MacGyver

Date Posted: Aug/01/2018 at 6:10pm

|

Wow!!! Thank you for the link!! And thank you Kenny, for making that video!! |

Posted By: Rebel Machine

Date Posted: Aug/01/2018 at 6:48pm

Posted By: bobsterfl

Date Posted: Aug/02/2018 at 12:22pm

Posted By: bobsterfl

Date Posted: Aug/02/2018 at 12:25pm

| Oops. First, thank you for posting this information. Just one final somewhat related thought from my own bad experience. If you use some kind of washer to shim the end play in the distributor, make sure that whatever size washer you use has an outside diameter SMALLER THAN the root diameter of the distributor gear. I made that mistake and tore up a perfectly good set of gears by using too large a washer OD. |

Posted By: PHAT69AMX

Date Posted: Aug/04/2018 at 3:12pm

|

Yes, thanks, if shimming Distributor Endplay the OD of the Shim must be less than the Gear Root Diameter. Her's a random "sideways" crazy thought... Wonder what an AMC V8 Gear and a Small Block Chevrolet Distributor Gear look like side by side? Wonder if the Shaft Size is the same, tooth count etc... EDIT: some surfing found these dimensions, unconfirmed: EDIT: updated with info from bobsterfl - Thanks ! DISTRIBUTOR SHAFT DRIVE GEAR (s) 0.491" Dia. = AMC Distributor Shaft, Delco & ? Type ( 13 ) = Number of Gear Teeth 1.040" = Gear Teeth Outside Dia. 0.785" = Gear Teeth Root Dia. 0.620" = Gear Teeth Length 0.491"?Dia. = SBChev Distributor Shaft (update 10-27-18) ( 13 ) = Number of Gear Teeth 1.25x" = Gear Teeth Outside Dia. 1.0xx" = Gear Teeth Root Dia. 0.71x" = Gear Teeth Length -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: bobsterfl

Date Posted: Aug/06/2018 at 7:18pm

|

OK, I just went out in the garage and measured an OEM distributor gear that I have, and here are the dimensions I measured: (All +/- based on my cheap dial caliper) Gear OD: 1.040" Root Diameter: .785" Gear length: .620" Hope this helps. Bob

|

Posted By: PHAT69AMX

Date Posted: Aug/21/2018 at 5:05pm

|

Thought no harm adding this overall AMC Block Oil Circuit Diagram here: ( guess this drawing does appear to show the Timing Chain Sprocket Front Face Oil Groves )  -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: amx600rr

Date Posted: Aug/21/2018 at 6:47pm

|

And it left off the fuel pump eccentric and distributor drive gear so it doesn't show the oil feed passage to the drive gear..... but shows all that WASTED oil slinging out to the timing chain and starving the Distributor gear. Jerry |

Posted By: PHAT69AMX

Date Posted: Aug/21/2018 at 9:02pm

|

Yep, agree, that video shows it plain as day... Right now I am bumming out because I no longer have parts and am unable to find a picture of a Timing Cover on a Block without the Oil Pan on the Block so I can get a visual of the Timing Cover & #1 Crank Bearing Cap and resulting Oil Drain Back restrictions or limitations, if any...

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: PHAT69AMX

Date Posted: Oct/28/2018 at 1:09am

|

Found some very interesting AMC Traco Trans Am Engine info in of all places a 1st Gen Camaro Forum... Like a not previously seen Oil Drain Back Hole Addition Mod to the Cylinder Heads ( pic )...  And this interesting post by CRG Forum member Pigpen, a former Traco Employee: "TRACO (Jim & Frank) didn't actually become famous because of Chevys or for that matter AMCs. Yes the Javelin engines put out a little more than the same CID Chevys, but the early AMC track engines could not stand the corners without starving the oil pickup, so there were many not so spectacular blown engines. There's a lot to be said about the compact design of the small block Chevy, the design facilitated oil return flow from the upper portion of the engine to the oil pan, and there were not a lot of places for the oil to get trapped. Small block Fords and AMC's had a lot more room in the lifter valley and around the crank, so oil tended to get trapped. The ultimate answer for the AMC's was to run "Dry Sump". Another interesting difference was the Cyl Head design, Chevy heads had better flow characteristics and required less valve lift than the AMC's, so Chevy cams took far less punishment. For the bottom end though, the AMC's were very strong through the main bearing area, where Chevys were prone to main web cracking. Each engine has goods and bads, the trick is enough power and lasting through the entire race." Pigpen And here's pics from Eddie Stakes page showing one possible Timing Cover Drain Back Mod:  -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: Rebel Machine

Date Posted: Oct/28/2018 at 6:54am

I took this pic when I first got my Canton pan. This photo was taken looking straight down along the back side of the timing case into the pan after I beat the front of the pan flatter to align better with the timing case.  Pan to timing case fitment looking at back side of timing case.  Here's the pan to main #1 clearance.   |

Posted By: 401Ambo

Date Posted: Oct/28/2018 at 7:29am

------------- '72 401 Ambassador wagon '69 pro-Street AMX AMX/2 (starting soon) |

Posted By: PHAT69AMX

Date Posted: Jan/23/2019 at 9:22am

|

Just a middle aged hobbyist Hot Rodder guy. Had a '69 AMX from 1985 to 2014. Paid shop to do 1st motor rebuild. Self-assembled the next three. Web active since about 1995. Not my ideas, those of many others. Collected many little "Oil" things that can be done. Mandatory? Doubtful. Helpful? Maybe. In no way an endorsement, just a compilation. Quite a bit here really once all typed up. Sure there are more, will edit / add as needed. Kinda 2 categories: - Do things to what is already there - Add, change, replace things AMC V8 Oil System Checks and Modifications Obvious - Cam, Crank, & Rod Bearing Clearances to AMC SPEC - Pick-Up to Pan Clearance to Spec Lifters - ? Correct FIT Lifter to Bore, .904 Lifter OD and Lifter Bore ID - ? Lifter internal design, oil volume passed - ? Restrictor Push Rods Rods - ? Bearing Oil Squirter Notch at Rod / Cap JointOil Pump - Deburr New Pump Gears and SHAFT SLOT to prevent any damage to shaft hole in Timing Cover - Temporary Assemble New Oil Pump Gear and Actual Distributor that will be used for Final Assembly w/o Drive Gear to Confirm NO BINDING between Pump Gear Shaft Slot & Distributor Shaft Drive Blade - "Parkman Mod" ? at bottom of Pump Gear Pocket for "anti-surge" - enlarge / port match Round Outlet Hole in pump cavity pocket - use late angled cover rather than early 90 cover - block off filter bypass, or new cover with out - change threaded filter Adapter for one that fits larger later filter - inspect Pressure Relief Plunger Passage for finish and size - soften / blend oil passage intersection corners where possible Oil Pan - ? run approx 1 extra Quart, more than 5, less than 6 - ? aftermarket larger Aviad oil pan, but significant cost Block - port match Block Front Ports to Gasket / Timing Cover - confirm / clean drilled passage from pump up to top center oil galley - blend / soften internal oil galley intersection corners where possible - 3/8 Pipe Plug - SHALLOW, Pass Side Front of Block - confirm full drill through Main Saddles up to Lifter Galley - inspect oil pan rail suction passage - Pick-Up, confirm no galley obstruction once screwed into pan rail - ? add ~1/8 oil drain holes in lifter valley, or others ? - ? Chamfer / Blend 2 Front Oil Drain Holes ? Drainback - deburr / blend lifter valley drain back corners - ? Modify bottom of Timing Cover at Front Bearing Cap "gap" area - ? Traco Mod, small hole drilled through between Pushrod Holes in Heads Heads - inspect / blend / ? enlarge ? cylinder head drain back holes - No umbrella seals, machine valve guides for Perfect Circle Valve Stem Seals Cam - Correct Cam Bearing Installation Oil Hole Size & Location - confirm front snout stack-up oil passages - Cam Sprocket, ? Front Face Slinger Grooves, size and quantity ? - Full Groove front most bearing and/or journal - bleed hole rear most bearing journal - Rear Freeze Plug installed depth -------

You mean to tell me the new "better than anything before or since" Chevrolet LS V8 Motors have an Oiling Circuit that is more like the AMC !, that being the Oil Pump is now in the Front with a longer Suction Side and it oils the Lifters FIRST and the MAINS are LAST ! Am I seeing things !

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: Trader

Date Posted: Jan/23/2019 at 3:40pm

|

Strikingly similar except for the path at the block rear of the lifter galleries. This would provide even oil pressure in both galleries. The bypass line familiar to everyone is used to ensure pressure front and rear on the right gallery. The LS is a bit better on the supply side with the "ring" oil gallery - my opinion. The suction side - the shorter AMC version gets my vote. The left gallery on the AMC with so little flow was always the first side to build up any "contamination" and the lifters seem to always stick on this side first.

|

Posted By: PHAT69AMX

Date Posted: Jul/22/2019 at 1:17am

|

Well look what I stumbled upon on the Holley / MSD / all else they now own Web Site... in their Troubleshooting Techniques area... "Modifying AMC oiling for performance" hmm.., any of you all seen this already ? https://www.holley.com/support/troubleshooting_techniques/#AMCModify" rel="nofollow - https://www.holley.com/support/troubleshooting_techniques/#AMCModify

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: White70JavelinSST

Date Posted: Jul/22/2019 at 1:49pm

|

Looking at the picture that Phat posted and came from Traco showing holes drilled in the heads between the pushrod pass through holes. My thought is they only help when the amount of oil in the rocker area is deep enough to flow into those holes, which is what? Maybe a quart or more in each rocker area?? But if the engine is running 7 or 8 quarts, no problem. ------------- 70 Javelin SST, second owner, purchased 1972 |

Posted By: PHAT69AMX

Date Posted: Jul/24/2019 at 2:58am

|

THANKS TO REBELMACHINE, 401AMBO, 67 MARLIN, AND ALL OTHERS WHO HAVE CONTRIBUTED TO THIS THREAD ! 72POS has videos posted on his FaceBook page of his highly modified AMC race motor running and looking down in the Valve Cover Breather Holes and you would NOT BELIEVE the amount of OIL circulating around inside those Valve Covers ! Those 2 Oil Drain Back Holes on the corners of the Heads must just be very restrictive relatively. And they drain into the Lifter Valley -NOT- the Oil Pan... and the "path" from head to valley is kinda of a more Horizontal flow path than vertical... Plus all Hydraulic Lifters are -NOT- created equal and who knows just how much volume of OIL is pumped up top by whatever brand current replacement lifter from the myriad of manufacturers compared to the volume of oil pumped up onto the heads by stock original AMC Hydraulic Lifters ?...

-------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: rgsauger

Date Posted: Oct/28/2019 at 10:06pm

| Damn brilliant! Man there are some knowledgeable cats on this forum! Can't wait to start on my 360 for my Cj in a few months. |

Posted By: Rebel Machine

Date Posted: Oct/29/2019 at 7:03pm

I did this type of testing a few years ago when I was chasing an oil pressure problem. Running the oil pump with a drill won't flow as much as if the engine were running for a couple of reasons. One reason is the oil is cold and thick when using a drill. Another is since things aren't moving feed holes aren't moving around and being lined up with the pressurized oil feeds during rotation. For my testing I looked at the drainback paths in the heads as well as how much was flowing past the crank bearings. Got video of running engine valvetrain oiling and drill driven pump valvetrain and crank bearings. Instead of restricting the oil feed in the block I used restrictive pushrods. Easier to change if need be. -Steve- |

Posted By: Hurst390

Date Posted: Oct/30/2019 at 4:26am

|

I've never blown up an AMC going around corners with a wet sump pan. ------------- SC/Hurst Rambler 11.62 120 100% Street Legal |

Posted By: White70JavelinSST

Date Posted: Oct/30/2019 at 11:29am

Penske racing blew up Traco built AMC engines back in 1970. Tha was before Traco figured it out and SCCA allowed dry sump oiling. ------------- 70 Javelin SST, second owner, purchased 1972 |

Posted By: BassBoat

Date Posted: Oct/30/2019 at 1:48pm

|

Hurst390 do you run a pan with more volume, something like the Canton road race/street oil pan, or if you have something you made can you describe it? |

Posted By: Hurst390

Date Posted: Oct/30/2019 at 5:23pm

------------- SC/Hurst Rambler 11.62 120 100% Street Legal |

Posted By: bwamx

Date Posted: Oct/30/2019 at 7:23pm

|

Are those oil drain back lines from the valve covers On the drivers side of the oil pan? We use to run those along with a Similar home made oil pan on a IMSA hornet before going to a sump system.

|

Posted By: Hurst390

Date Posted: Nov/01/2019 at 4:50am

------------- SC/Hurst Rambler 11.62 120 100% Street Legal |

Posted By: PHAT69AMX

Date Posted: Nov/01/2019 at 12:34pm

|

This is just a drawing I know, and rotated into position in PowerPoint to create this image, but it gives some general idea of the amount of slope in the stock cyl head oil drain back holes and just how shallow, or just how little slope, there actually is in those drainback passages. I'm fairly confident this is correct, 45 deg block deck surface, cyl head drawing oriented as-if on block.  -------------  Link to a http://www.youtube.com/watch?v=MySiKQsmWxU" rel="nofollow - Short YouTube Burnout Video |

Posted By: amc67rogue

Date Posted: Nov/01/2019 at 2:25pm

|

( Full Groove front most cam bearing and or journal !) All front cam bearings had a grove in them The early camshafts ( 66 early 68 ) did not have a grove in the front cam journal. The first couple yrs. they had a lube problem with the Cam and Dist. gears. There was a Field Fix from the dealers to tee a oil line from the pressure switch to the front cover to get more lube to the gears. All 68 and up cams had a grove in the front journal. NOW 50 plus yrs. later there is a mix of flat tappet cams that do not have the front journal grove. All of the roller cams I've seen DO NOT have the grove. ------------- Keith Coggins 67Rogue X code |

Posted By: RobinPDX

Date Posted: Jan/19/2021 at 4:52pm

------------- Rob Wiley |

Rebel Machine wrote:

Rebel Machine wrote: