73 Javelin brake and suspension project

Printed From: TheAMCForum.com

Category: The Garage

Forum Name: Suspension, Steering, Brakes & Wheels

Forum Description: What makes it stop, turn, and smooths the ride

URL: https://theamcforum.com/forum/forum_posts.asp?TID=92968

Printed Date: Apr/19/2024 at 5:57pm

Software Version: Web Wiz Forums 12.03 - http://www.webwizforums.com

Topic: 73 Javelin brake and suspension project

Posted By: billd

Subject: 73 Javelin brake and suspension project

Date Posted: Mar/09/2018 at 6:55pm

|

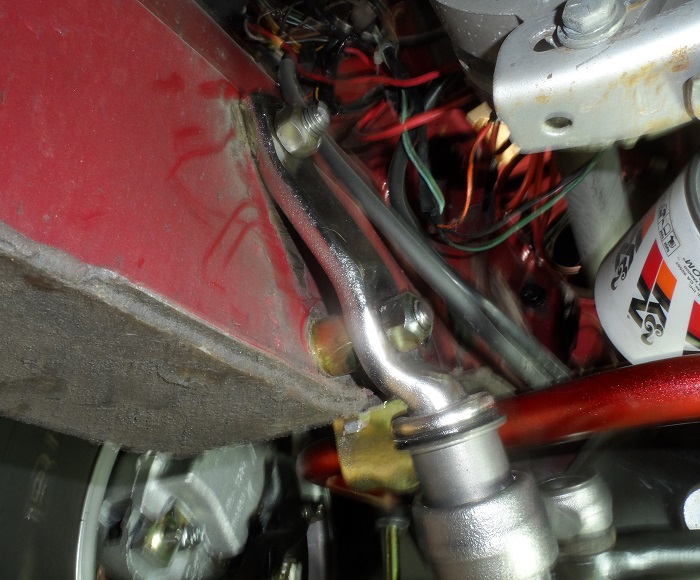

This isn't going to be to the same level that I took my 70 to as this car is very modified and has had a rough prior life. I'm attempting to give it the TLC that it needs, priority making it safer but nicer as I can. The car came to me with power DRUM brakes. 73 Javelins had ten inch front drums. The brakes worked fine but I gave my front brakes, spindles and all, to my neighbor for his car as I figured I could use the disks of an 80 Concord wagon I'm parting out. Well, yeah - it was REALLY rusty so the shields were mostly gone, rotors very rusty (could be cleaned up I'm sure as they have not been turned before) but it was just a bit much by the time I spent money on all new bearings and seals, new calipers, new pads, having rotors turned, hoses and so on, It wasn't going to save me all that much in the end especially when I considered the time spent. So I bought the disk brake package amxess had for sale here in the forum and brackets from mrblatzman (both Steve and Bob great to deal with and good parts) There was no use doing all of that and not deal with the worn out bushings and other parts - the car has over 90,000 miles and again, had a rough prior life. So, similar to my 70 the entire front suspension is coming off,, all bushings being replaced, ball joints, tie rods, front springs (one was broken and they had twist-in spacers in the coils) But most parts will be painted and not powder coated like I did with my 70. With that car I powder coated almost everything including the coil springs! This will be a sort of show car, but mostly a fun car. the process started a full year ago when i told my neighbor that if he'd come over and pull the front brakes and spindles he could have them. It's been up on stands all this time. Time to get it finished up and back on the road. As you can see here - the strut rod bushings are TOAST. One was literally mushy and falling apart. (and started to wear the bracket hole) The lowers are from my 70 - I put NOS lower control arms on it and saved those because at that time they had only about 25,000 miles on them. So I cleaned and painted them and put in new bushings. The uppers are CRUSTY, greasy, nasty and will take a couple of hours just for basic cleaning. Spring supports are rebuilt and nice with new bushings and fresh paint. Most parts are here except upper ball joints and those are coming from Amazon the first of next week.  Maybe you can see the PO patched the battery area, not really well but better than a hole I guess.  Left side - haven't gotten the control arms off yet - do have one of the bolts out of the upper. Have to scrape tons of grease and gunk before I can get the lower off this side......  Parts, some ready to go...  More parts and the springs from another 73 I'll be using...  Spring supports all rebuilt and ready, most of the new suspension parts......   -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Replies:

Posted By: 304-dude

Date Posted: Mar/09/2018 at 7:40pm

|

Billd, i dont think anyone here will make a comment on what works best, or how they would substitute for a diff part. Most of us will just sit and watch with a beer in hand to see how you go about a complete front end rebuild, it a rarity on the forum, as most threads are varied in depth. I did not notice if you plan on tie rod ends and steering as you are deep in the parts replacement area. We pretty much know you will pay good money for parts that are proper or in this particular case, are worth buying. IMO NOS is best and can be more economical in the long run. As NOS parts can be 2x or even 3x the money for your average part. I think you have been very vocal on keeping up on clarifying other people's threads, expecting the new or less experienced to know reasons why one did or chose something, when not pointed out or overlooked in discussion. Not sure, but i do believe you chose old stock Moog over new? Not that we are to have a long drawn discussion on pros and cons, just it may help to have some help on parts selecting if, you had to obtain bushings, brake components and ball joints from a fresh at home rebuild. Just thinking out loud, as it is early and enough time to put some input in on your thoughts before things may jumble around. ------------- 71 Javelin SST body 390 69 crank, 70 block & heads NASCAR SB2 rods & pistons 78 Jeep TH400 w/ 2.76 Low 50/50 Ford-AMC Suspension 79 F150 rear & 8.8 axles Ford Racing 3.25 gears & 9" /w Detroit locker |

Posted By: Lyle

Date Posted: Mar/09/2018 at 8:35pm

|

Bill, You probably know you are missing the top polymer on the torsion bar in your picture. If you haven't already ordered the parts, Mustang torsion bar connecting bolts are the same and cheaper to buy the bolts and bushings set then just the AMC bushings. Have you taken the fenders off and looked at the troughs? They are structural and can be repaired. The gas line going through the frame - have a good look, mine was half eaten/worn away. Dust shields I made myself, 18 gauge and a bead roller. Template was the old rust shield - all it was good for. A little tighter to the disk but no issues. If yours had the same tough life as mine check the frame for square and bend. Mine was out of square 3/8" and 1/2" twist. Braces and Enerpack got it back, alignment 0.01° thrust line and 0.002° front to back frame. Mine came with sub frame connectors so I cut them off and replaced with same (new fabrication) after straightening. Mine was never registered for the street so I believe it was race or other special order, just guessing by the twisting, sub frame connectors, rear end yanked out more then once and transmission casing pieces ripped into the rockers. Have fun:) |

Posted By: billd

Date Posted: Mar/09/2018 at 9:56pm

|

Lyle I wish you could have seen the link on that bar on the right side...... the bolt had broken and hammered on the lower part so much it had worn it smooth and the upper part still in the bar was now bent and worn smooth. Obviously it had been broken for a lot of miles. I knew it was broken but was waiting until it was all apart. I thought I had a link kit (the long bolts, spacers, washers and rubber bushings) from another project I didn't need..... if I don't. For one of my other cars I bought a kit at NAPA - it was less than twenty bucks and since they are pretty universal, I just told them what I wanted, no need to specify the car. On the dust shields - I have none. The ones from the Concord I was GOING to use the brakes from were so rotted there wasn't anything to get a pattern from. Fourth photo down shows remains of the better one in the far left part of the picture. And those were Bendix brakes. I bought the heavy-duty KH brakes from amxess here on the forum - the setup he had for sale for 300. He had everything except the shields - so I'll be looking for a pair. I have NO shields at all - nothing, zip - I really would want shields because they also help with road splash,, etc. and it rains a lot and our old roads hold water and the roads are dirty after winter's sand trucks keep laying down a beach worth of sand each winter. So if I can find the proper shields for THESE brakes, I'd be happier. I don't have to pull the fenders to know about the gussets - the front ends are rotted about an inch or two back from the front. They appear solid otherwise but the left one is also needing attention where it joins the car at the back - I can stick a finger between the back end of the gusset and the firewall area up in the wheel well. And I know the right front has been welded back of the headlight and where the upper rad support connects. I will be pulling fenders in the future, but I know I need to work on the gussets at the front and on the left side, MAYBE at the rear. (I REALLY wish I was a much better welder!) The car seems straight - things line up really nice, no odd gaps, no broken glass - all original glass, tires didn't wear weird (odd for the shot bushings I'm finding) Anyway, I DO need to replace or rather REPAIR the gussets - I suspect only the front couple of inches. I have a NOS left fender, would LOVE to find a new right fender as well. My take on the car after owing it for 2.5 years is that it sat for several years,, the prior owner did some patching, replaced carpet, replaced the floor sills (and left out the seat belt anchor points but that's another topic!) Basically the car is an unfinished project - and the PO said as much. He was a paint guy, not a mechanic and was really bad with electric and interior work. All I'm missing are the upper ball joints - and I think I have the "sway bar" links in a tub of parts. It needs shocked (one was broken and the other was bent and had zero resistance up or down) 304 - I know it was impossible to tell from the photo because it was all boxes and such - but there are two inner and two outer tie rods in there, new sleeves and clamps and bolts and nuts. I did forget to order an idler arm but I haven't checked this one yet - it will likely get replaced either now or soon ,but the tie rods - all four ends are already bought and in those boxes. I had NOS lower control arm bushings but it's not wear or use - it's AGE that also kills rubber parts, so I opted to not use the NOS bushings when I saw one of them already had a crack starting. I had two sets of upper control arms on the shelf and the arms still in the Concord besides those in this car - will pull them all and lay them out and choose the best of the four sets/pairs to use. Calipers brand new, rotors brand new, bearings and seals brand new, pads brand new, caliper brackets new, hoses brand new (and bought the rear brake hose too while I was at it) so all brake hoses will be new. I plan on new brake lines, especially after seeing the brown/gray mud that was in the old master cylinder. Can't flush that out well enough. I laid the Concord rotors on my bench next to the NEW rotors and it appears like I may have to space my spindles out about two washer thicknesses - that's a GUESS only, based on how the surfaces of the rotor sit compared to the bearing areas. I'll know that later when I dry fit everything. I plan on doing a dry fit, mocking things up, not tightening anything until I see how things fit and where I may need spacers. Again, it won't be the perfect pain-staking restoration of my 70 front end, I spent a ton of time, efforts cleaning and totally de-rusting, powder coating, NOS control arms and more, on that. I left no stone unturned. It was also a 25,000 car when I did that so there wasn't wear, it was just time and bushing rot that needed fixing there. Even the cross member got blasted, treated and powder coated on that car. I cleaned every part one at a time in my electrolysis bucket, phosphate treated, powder coated, etc. This will be good, it will be safe, it will be better than it ever was before (the HD disk brakes will see to that) but it won't be an AMO show car. On the other hand I am already struggling with "where do I stop" and having to really try very very hard to resist the urge to make it perfect. My Eagle was supposed to be a "get it on the road and paint it" daily driver car and ended up with a car good enough to get a high score at AMO (and a trophy) I just MUST resist the urge to do this one to such standards......... I may need someone to come by and hold me back on it now and then. I cant afford the time and money to do another car like I did that one. (and it's STILL not done - I have another tub of NOS parts to put into it) -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: 304-dude

Date Posted: Mar/10/2018 at 5:13am

|

About holding back... one thing that may help. Always keep function a priority, limiting on how much does perfect look effect costs. But it seems your wife knows you best, so have her manage your car. Tell her what's most important... safety, and proper fit with a limit on costs, having comparisons of what is available. Then she either OKs or disproves. I know you cannot help your self with being use to doing things your way on your car's and others. Spend time with my cousin, and eventually seeing how he can do things on bare minimum, can break your locked in thoughts of what is proper. Not saying an old rusty item will do the job just as well... Seems you broke me from commenting on ideas on not using NOS, because your locked in on it. I don't see the parts you got as an issue, but in some ways, they be over kill, only by that they are NOS. Considering you may have saved some coin in hunting at the next swap meet, your standards my have made 3 events unfruitful. So taking the plugs to get such parts is a bit of a god send. The best example I could think of is my parts I sold from my car. I could not replace them to the same or better without some extra costs, if i were to return it back to stock. Not that I sold low, just by overall condition. Even back then in 2005 not every thing being offered was of 80s and 90s condition. An easter egg hunt for most, and especially now. I am lucky with being able to keep things frugal while still opting for the better made products available over the counter. Time to be so was and still is not part of the equation. Knowing you want to get it done, makes time part of your equation. Ah, about NOS bushings... i understand about that, and has been part of your posts here and there... you just cant trust old rubber to stay perfect over time, no matter NOS or od stock OEM replacements. Just assumed you got a good OEM replacement set from NAPA or whoever. ------------- 71 Javelin SST body 390 69 crank, 70 block & heads NASCAR SB2 rods & pistons 78 Jeep TH400 w/ 2.76 Low 50/50 Ford-AMC Suspension 79 F150 rear & 8.8 axles Ford Racing 3.25 gears & 9" /w Detroit locker |

Posted By: Lyle

Date Posted: Mar/10/2018 at 6:36am

|

NAPA - arggg! - new engine seals installed and leaked after 2 months of service. Still had the boxes, 18 year old seals by the date code on the box, looked after the fact - dumb I know. In the Nuclear industry they didn't last two years on the shelf and were changed every 10 to 12. Yes, old elastomers are just that, expect reduced service life. |

Posted By: billd

Date Posted: Mar/10/2018 at 7:52am

|

Lyle - The sway bar links I bought were basically exactly the same as the originals I took out of my 70 and they are still i the car and still look like new.. There's little that could go wrong there unless it was a cheap grade 2 bolt or something. However, that was years ago so........ and yes things like seals and rubber parts - beware and check dates, dust on the box, etc. I hear ya. Dude I have no clue what you are really trying to say - as they used to say on Laugh-In "you lost me at the bakery". Totally. As far as doing something right - that's the only way I know. Part is my education and history - been at it since age 14 and worked for two "old timers" who were the very best in the game. You never wanted any come-backs. Besides - no, I can't do any other way and no, crusty/rusty parts won't do. You have no clue as you have not dealt with ADHD nor are you OCD. When someone sends something my way they know when they get it back it will work, it will be right. Now some things I understand about not being able to use the very best first time - sometimes something can't be had or there's no money - but suspension, steering and brakes are one thing I will never do a second time. If I can't do it right once - I wait. I don't mind swapping out marker lights, tail lights, trim, a clock, seat trim, a door handle, but other things it's DUMB to do it two times. Why spend hours on something and then later do it all over again. Do you enjoy taking out springs so you can swap parts and spending half a day doing it again? Not sure where the constant talk of NOS keeps coming in - nothing in the pictures was NOS except perhaps the tie rod sleeves (and I wasn't trying, there) or perhaps the rear brake hose brass block (again, not trying, it was the first thing I found) Otherwise NONE of the brake parts - NONE - are NOS. They are NORS. Not one of those parts came from an AMC dealership in AMC boxes. The only NOS brake parts are what I got from Bob - and again, I'd have taken used ones but good luck - all I could find at the time were what Bob had and his price matched what used ones would have likely sold for on eBay. Can't beat a brand new bracket for twenty bucks - did you have a set you'd have sold me for that? Did you LOOK at the pictures? Do you know what those yellow boxes are? Not NOS. The calipers and their brackets were painted silver - hardly NOS. New parts, yes - but not directly from the AMC factory. They are nice, EXCELLENT parts and a great deal. I knew what I was getting and am 110% happy with them and would do it again. But new, not NOS. I don't want amxess/Steve to get the wrong idea - I KNEW what the parts were and that is why I bought them. The deal was good, the parts were very very good and I'd do it all over again. These will make GREAT brakes and I'm TOTALLY happy with the deal AND the parts - ZERO negatives there. (Of course we know AMC didn't make their own brakes so you could hardly truly buy NOS brake parts.) I'm simply trying to explain to someone who apparently doesn't get it that I wasn't holding out for NOS parts and geesh, I shouldn't have to justify what I'm doing to a certain person on every single project.

Why do you keep trying to tell me how to run things? Really, I get a lot of lectures but you don't know me or my work. I've done this probably longer than you've even been driving. My wife always says "do it right or don't do it at all" and "don't cheap out, you know you'll just end up buying it again later". She's a perfectionist. (you'd know that by now if you paid attention and stopped trying to train me) I was half-joking, a point those who know me or try to would have gotten and understood. But again, I know one way of doing something, and that's safe and right. The finish or removal of rust, etc. is a matter of my "medical situation" and cannot be changed, at least not easily. (too bad more people don't strive for perfection or totally enjoy a job well done to the best of their ability) Anyway, PLEASE REFRAIN - this is about my car and how I am doing it - not your attempts at psycho-analyzing things. I am truly absolutely afraid to post a thing about my projects for fear you will pop in with a rant about me, my personality and how I do things. My fears were not unfounded.

Wow, I was right - you are clueless and TOTALLY wrong. Why do you keep trying to TEACH ME when I have taught this stuff to others over the years? I'll put my knowledge of cars up against you any day of the week. First, those are NEW parts, not "old stock Moog". good grief - you really don't have a clue. The last thing I need is you telling me how to select parts. How the heck long have you been doing this? Me since the early 1970s - and I have the trophies to prove it and the certificates and the degree and the letters of recommendation. Did your state's biggest AMC/Jeep dealership call you out of the blue and offer you the service manager position - based only on reputation? Did you ace the Plymouth Troubleshooting written test- a record never broken, and set record time to judging with only one point lost (a hose was above another in a clip and they should have been reversed in the clip but the connections were correct) I've done more suspension and brake work than you'll ever do in your life - I used to make my living at it. Why is it that you keep trying to fix me when others, like Lyle, Red Devil and others are very helpful with solid information? Sorry, folks, but I'm at wit's end with that BS. I may or may not post again in this thread. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/11/2018 at 4:11pm

|

Just couldn't help myself - was doing some other parts for other projects and decided, what the heck, can't stand rust on tie rod sleeves. I've done too many dozens and dozens of alignments where the sleeves were rusted to the tie rod ends and have to heat or beat or whatever. Not these - and they sure do look pretty. Also plated the threaded end of the right strut rod to help slow any rust........ will do left after I get it removed and cleaned up. Yellow bright zinc on the sleeves and black zinc on the clamps and yellow zinc grade 8 bolts and lock nuts.   -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/11/2018 at 5:15pm

Over the top Bill.

-------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/11/2018 at 8:53pm

Ya really think so? Man, they sure are pretty in person. Hey, if the interior can be Pierre Cardin, the underside can have some art, too.  If I had time I had actually thought about bright zinc plating some of the suspension parts - naw, would take forever. The rest will get painted. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: LakesideRamblin

Date Posted: Mar/11/2018 at 11:16pm

|

Those sleeves are perty! Never have seen how you or anyone else zinc coat parts. Would you mind showing a picture of that process. Very curious. Thanks. ------------- LakesideRamblin 69 Rambler 360 73 Javelin 360 "If you could kick the person in the pants responsible for most of your trouble, you wouldn't sit for a month." T. Roosevelt |

Posted By: pit crew

Date Posted: Mar/12/2018 at 7:21am

-------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/12/2018 at 9:21am

|

Well honestly I have come to EXPECT that sort of attention to detail and those fun little things in the stuff you do. For the plating, you start with lots of cash - Nearly $700 for the plating rectifier or power supply (in my case, a programmable digital power supply) About $1300 for certified 99.99% pure zinc bars which I cut into slabs to fit my anode hangers and will fit into the anode bags. About $25 for anode bags - special filter bags the anodes are placed in before hanging them in the solution - it prevents zinc sludge and crap from getting suspended in the solution and making the plated surfaces rough. Hangers and stands to suspend the parts to be plated from - in the solution. I made my hanger stands and made the hooks and racks using brass and copper which you MUST nickel plate to prevent copper contamination of the plating solution. Some have their racks coated with a special plastic but I did the nickel and then powder coated them to seal the copper and brass away from the plating solution. About $800 worth of chemicals - 200 of that is common ammonium chloride, zinc chloride and potassium chloride I order from various sources and the other is the proprietary chemicals I buy from an international plating chemical supplier. I work with their chemists, etc. when I run into any issues. These can only be shipped via freight and to a business address due to their nature. Then there's a supply of ammonia and HCL to keep the pH of the bath at about 5.3 - add acid if it gets too high, ammonia if it gets too low - doesn't happen often but there's "drag-in" from the pickle bath or metallic and other contamination that can happen. I've had to balance the pH a couple of times in the last two months or so. A supply of disposable rubber gloves, plastic aprons (remember, it's ACID), goggles and such. Tons of water for rinsing between every step - DISTILLED water for many steps. An acid bath for stripping zinc, etc. A special caustic cleaning solution run at about 180 degrees to clean the parts of any grease, oil or other similar substances. A few hundred bucks worth of the various chromate or passivate solutions - yellow passivate, clear/blue, and black are mostly what I use. Each has to have it's own "tub" or container and the yellow I run at about 100 to 120 degrees. Parts must be beyond perfectly clean and pass a water-break test - water must NOT bead up on the cleaned metal surface. It must evenly wet the surface and not bead. So you strip all rust, dirt, whatever and get it so clean you can't see a speck of rust anywhere. You soak it in the cleaning solution, then rinse it, then remove any prior plating using acid, rinse the heck out of it (and I double-check after this, often going back to the caustic hot solution) then sort of depending - a judgement call IMO, a pickle solution consisting of a special mild acid that activates the steel or iron or cast zinc item to accept plating more readily. Then the part gets hung from my hanger on those special hangers and rods and hooks I've made and put into the plating solution/bath. I apply the power to the zinc anode racks and to the part/parts to be plated via their hanger/rack - I have to know the surface area of the part so I calculate that and apply a formula so that I apply roughly 15 to 18 amps per square foot. Now on smaller parts - I do end up using a calculator and often work with power in the tenths of an amp. The two sleeves I ran at 3 amps for 40 minutes (programmed my plating rectifier for that) and the clamps I ran at just a bit under that, but close to 3 amps. I've done small parts at .25 amps and as much as 14 amps. I can go as high as 25 (I think it's 25) with my plater. Once plated, I rinse the part, NEVER TOUCHING IT, run it in the passivate - the sleeves in yellow, the clamps in black - and do a very light rinse then hang them for 24 hours to dry and set. The passivate is very fragile at first and if you touch it or mess with it at all you start over. I haven't calculated my total costs but it's in the thousands. Oh, I nearly forgot - you have to circulate the plating bath and filter it constantly. ANY fine material in the solution can cause roughness. So I have two small filters and three pumps circulating the solutions. Luckily I can use CHEAP stuff there - aquarium pumps work fine if you get enough GPM out of them. I have to keep the plating tank at 80 degrees and aquarium heaters for for that as long as they are glass or some other very neutral material, and I use aquarium heaters. I have to use stainless steel tank heaters for the passivate as it's harder on stuff. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/12/2018 at 9:23am

|

Heading back out to the shop soon - got the right lower arm mounted and some of the right side parts cleaned and painted yesterday. The upper ball joints should arrive today. The upper arms are a mess - so we'll see............. even my best pair have rust and a few imperfections and have years of dirt, grease, paint - some multiple layers applied by others, and other crud Can't wait to get even just one side back together! -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/12/2018 at 10:47am

-------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/12/2018 at 5:22pm

Amen - ain't it the truth. I got the strut nuts cleaned up and plated looking not quite like new because of some minor pitting but still really nice. A few more parts cleaned up painted, etc. Here's the control arms from the right side- I had mentioned earlier that the right sway bar link had broken and was hammering on the ends etc. - you can see where it not only broke but the top part constantly hitting on the lower part and the arm wore it in an interesting way. Also a photo of the Kent Moore tool used to remove and replace upper control arm bushings. A press can be used but is rather inconvenient. I used my press on the lower arm bushings and I use this tool for the upper arm bushings........   pit crew this pic is for you  -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/12/2018 at 9:08pm

Pretty. Not a show car huh?  By the way. If the lower control arm is too beat up check part number  -------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/12/2018 at 10:03pm

|

I think the lowers are ok, but I had saved the original lower arms from my 70 when I rebuilt the suspension on it and put in a pair of NOS arms I got (with riveted in ball joints, etc.) The car had only 25,000 miles on it when I pulled the arms - they were dirty and needed a lot of cleaning and so on and wouldn't have powder coated as nicely as NOS but I wrapped and saved them. I cleaned them up pretty good (actually most folks will never see the rough spots) and have used those arms for the lowers on this car. Now to worry about the uppers - which are a mess - rusty and dirty. Ha - with those struts you'll not need to worry about bushings ever again. talk about heavy-duty. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: CamJam

Date Posted: Mar/12/2018 at 11:01pm

|

Just did this on my '72 Javelin... new coil springs and all. What a difference! The car was scary over 50 mph before... drives like new now. Everything on my front end is new now except the inner tie rods (they seemed ok). The mid-90s Grand Cherokee steering box is something I highly recommend too. And yes, your earlier front-end rebuild thread was a big help to me. ------------- '73 Javelin 360 (current project) '72 Baja Bronze Javelin SST '69 Big Bad Orange AMX (2018 Teague Heritage Award) SOLD  |

Posted By: billd

Date Posted: Mar/13/2018 at 5:25pm

|

Here are pics of the strut hardware I refinished. The strut bushings I have didn't come with the concave washers so I had to spend a hour cleaning these up well enough to plate them. Can't even remember where I got these bushings but they are new, not in any boxes, but without the large concave washers so had to reuse my rusty, greasy, thick with flaky rust parts. I mean thee rust was so bad I had to dig out big flakes and scrape and blast and finally use a Dremel with grinder tool to clean them up. Also pics of the right side partially together - but I have a question - I did not take this apart, my neighbor did when I gave him the drum brakes. I did take apart the Concord I was going to use parts from but it was snowy, windy, wet and COLD when I did that OUTSIDE. I'm wondering about the thick flat washers and the split lock washers. There's only 8 of the thick flat washers and maybe that many of the old lock washers. My guess is that the LOCK washers were used with the drum brakes and the FLAT washers used with the disk brakes due to the thin splash shield. The locks make more sense with the drum brake thick backing plate. The thick flat washers make sense with the thin disk brake splash shields. I have the bolts, nuts and washers from two cars but there's not enough lock washers for two cars and not enough flat washers for two cars. So did these with DISK brakes use only the flat washers - and DRUM brake cars use only the LOCK washers under the nuts? And pics of an original DISK brake car to show which was used?? I stuck both on a couple just to keep things in place but I know that it was EITHER/OR and not both lock and flat on all four bolts - for one thing there aren't enough - but the flat washers show ZERO sign of a lock washer ever having been against it - they are too perfect. So I will guess - lock washers used on drum brakes, flat washers used on disk brakes due to the splash shield vs backing plate material and thickness.      -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/14/2018 at 11:37am

|

No one has the correct information on which washers were used with DISK brakes in 73? Did they use the thick flat washers behind the nuts for the spindle, or lock washers? I'm pretty sure it wasn't both - I am guessing they used lock washers for the nuts for drum brakes and thick flat washers for disk brakes due to the thin splash shield vs. the thick backing plate for drums. Looking to find out which washers were used where - what was CORRECT for DISK brakes on a 73 - the bolts, washers and nuts used for the spindle to steering knuckle......... And pictures or description of what was used where? -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: Red Devil

Date Posted: Mar/14/2018 at 11:57am

|

Hi Bill, From Amxess post:

Can confirm the nuts and lockwashers on mine are all on the inboard side ... but honestly don't know if they have ever been removed. Don't know if there's room for washers under the bolt heads and clear the hub? Hope this helps,RD |

Posted By: billd

Date Posted: Mar/14/2018 at 12:06pm

|

Does your car have original disk brakes? Does it use lock washers or flat washers? I have two sets of the four bolts - four of them have lock washers and four of them have thick flat washers. This tells me that AMC used EITHER but not both on the same bolts - What I'm trying to find out if the conversion i'm doing I should use the flat OR the lock washers. The problem with the parts book is that it doesn't really say anything - and it shows two different directions which I've never actually seen. The same reference number shows EITHER lock or flat - so it doesn't say "lock washers with drum and flat washers with disk". The half inch bolts, the larger ones that hold the caliper brackets on use lock washers - that's a given since they don't use nuts but screw directly to the other brackets. So I know about those - bolts and lock washers But the four that hold the spindle on - flat OR lock washers - for disk? -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: Red Devil

Date Posted: Mar/14/2018 at 12:17pm

| Mine has the factory original KH brakes ... but don't know if they've ever been fully disassembled? In the 28 years or so I've owned it, I've only changed rotors, bearings, calipers, pads, hose and hard lines. Will have to pull a rotor to check as I forget if it had washers under the bolt heads? Definitely nuts on the inboard side, and pretty sure with lockwashers ... but need to double-check. |

Posted By: billd

Date Posted: Mar/14/2018 at 1:29pm

|

Looking at the steering arms and the knuckle it appears only cap screws (bolts) and not flat washers because there's a pattern that fits the tiny shoulder or ledge under the head of the bolt (making it a cap screw, technically speaking) If there was a washer under the bolt head I'd not expect that pattern in the cast parts. COULD BE WRONG of course! -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/14/2018 at 1:35pm

|

OK, it's warm and dry enough I went out to look at the concord. Those parts are still sitting and laying there under the car, uncleaned. I appear to be very wrong - The pattern in the RUST and dirt would indicate fat flat washers on the bolts first, then the bolts were slipped in, then lock washers at the spindle. So if the CONCORD was correct, it was bolt head, flat washers, steering arm and knuckle, spindle, then lock washers and nuts. (I left out the disk shields because I don't have any!!) Good thing I bought new grade 8 lock washers. So they did use both. Interesting. Flat under the bolt head, lock under the nuts. There's PLENTY of bolt length and in fact it would be better with both because the bolts would protrude more without them. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/14/2018 at 4:56pm

|

I had to have the nuts totally snugged up to clear the rotor - if they were loose at all they rubbed - the lock washers of course pushed them out. I pulled the rotor off and tightened the four bolts for the spindle and put the rotor back. I then tried to mount the caliper to see how things would fit and - wasn't able to get the caliper on. The outboard pad was too tight against the rotor meaning that the rotor was out too far. When I did get it sort of mounted and snugged things up it was almost impossible to turn the rotor because the outboard pad was against it. There was plenty of space on the inboard side of things. The verdict - I have to machine the mounting area of the spindles to move them back inward so the rotor would move inward and give clearance. I have the right spindle almost done but stopped for the day. I've taken off about 1/8" so far and will take off a bit more and try it. I'll keep track of the dimensions - how much I had to remove compared to the original thickness of the spindle mounting pads and document that. Otherwise things appear ok so far. Sure glad I can machine those myself!! That way I can take some off and try it etc. The good news is - NO WASHERS - of course unless I screw up! The worst part is cleaning and prepping and painting parts - blasting, solvent tank, wire brush, ugh. I used my press to install the bushings but it was easier to install the sleeve with an original tool.... -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: MD Racer

Date Posted: Mar/15/2018 at 3:15pm

|

You have the bolts on the wrong way. The bolt heads should be to the disc rotor side and the nuts with lock washers on the back side toward the engine bay. ------------- 1971 Javelin 1971 Javelin SST 1971 Javelin AMX |

Posted By: farna

Date Posted: Mar/15/2018 at 4:57pm

|

I was about to say the same thing! Disc brake cars usually have the bolt heads on the spindle side, drum brakes have nuts on spindle side. ------------- Frank Swygert |

Posted By: billd

Date Posted: Mar/15/2018 at 6:59pm

|

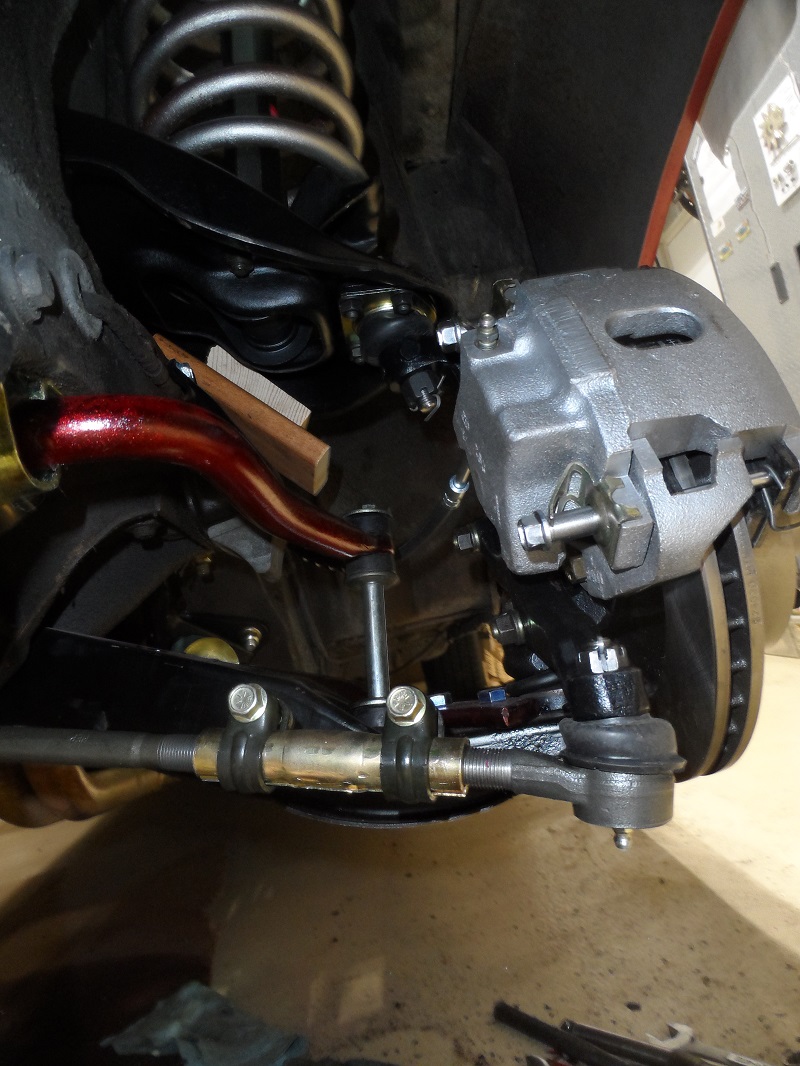

Farna is exactly correct......... the Concord had the bolt heads toward the rotor - the 73 Javelin which is what I'm putting disks on had the NUTS to the spindle and the bolts came in from the back. Farna nailed it. That is because the large nuts didn't clear the rotor back side. MD Racer is seeing my MOCK-UP phase - you don't put the bolts in through the spindle side when you are going on and off, on and off, fitting parts and machining the spindle, etc. Otherwise you have to pull the whole thing apart instead of simply pulling the spindle back off and leaving the bolts in place. And that brings me to my next "progress post". I machined the spindle mounting pads and got the rotor sitting right under the caliper. The rotor sat too far out as it was - put pressure against the outboard pad. So I machined until I got equal clearance pad-to-rotor on both pads when the caliper piston was fully retracted. In other words, piston clear in, pads in place, there is now the same amount of clearance between pad and rotor, inner and outer. To accomplish this I machined 0.100" off the back side of the spindles. It's taking forever - have to clean and derust parts, and some of the parts are really badly pitted and rough, and fitting things just right took a while. The right side is mostly together, the left is next....    -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/15/2018 at 8:13pm

That all looks so clean and pretty Bill. Now you just have to clean and paint the springs to match.

-------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/15/2018 at 8:20pm

|

I almost had to close my eyes when putting that spring in.......... but didn't want to take the time right now. Maybe in the future....... Yeah, I hated putting that thing in there like that. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: Lyle

Date Posted: Mar/15/2018 at 8:45pm

|

Bill, Your post 5:56PM, picture #3, part #8.835-1 from Red Devil's image. The boss on the bracket that holds the caliper is thicker on one side then the other. Are these parts interchangeable left and right side? If that part was on the other side the caliper would be placed inboard more, away from the rotor. Not saying what your doing is not going to work but looking at the pictures, have to ask so others may not have to go through the frustrations your having. I used an 81 Concord setup on my 69 Javelin and didn't go through what your enduring. |

Posted By: billd

Date Posted: Mar/15/2018 at 9:35pm

|

Nope - the brackets behind the spindle that hold the caliper bracket are two different part numbers and have a machined surface that the caliper bracket itself bolts to. The caliper bracket has a recess the bolts fit into and a flat side machined on the other side that mates to the bracket behind the spindle. In short, the bracket behind the spindle that holds the caliper bracket and the caliper brackets themselves have a left and a right - and have different part numbers cast into them. 8.835-1 is what I bought from mrblatzman (Bob) and there are a left and right. Remember he posted one for sale and we determined the part number he posted I believe was the right - he also had a left he sold me. They'll only fit one way, one side. Besides, the caliper would have had to move OUT away from the engine bay to work - the outboard pad, the one closest to the wheel, was what was hitting the rotor hard. So either move the caliper out or the rotor in. Since the brackets could not be changed and only fit one side, the obvious choice was to machine the spindles. Were the calipers and brackets you used the same as these? Remember, I'm using spindles from an 80 Concord with Bendix brakes on a 73 car that had drum and am mounting heavy duty Kelsey Hayes brakes. AMC also changed brakes somewhere in 81 - and even 82. I found three different disk brake setups - the brakes from an 81 I parted wouldn't work on an 82 and both were different than the 80 Concord! I'm not really "going through" that much - I could have waited and looked for the correct spindles for the HD K-H brakes for a 73 but opted to spend ten to fifteen minutes each machining spindles. ;-) I did them myself - so there was no cost or travel time. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/15/2018 at 9:56pm

|

What's causing the most pain and taking so bloody long is the amount of RUST and CRUD under the car. Yeah, it looks slick, runs great, etc. but the PO did ZERO for the suspension, steering and brakes. In fact he totally ignored the mechanical and suspension aspect of the car - to the point some parts crumble as I remove them such as the clips that hold brake hoses to the frame bracket, and the small snubber mount bracket that bolts to the frame with three bolts - totally rusted and pitted and the rubber "snubbers" were GONE GONE GONE. Inside was a quarter inch of rust and crud. It takes a lot to get that out - with chisels and so on. Can't blast it as it's too hard. Even electrolysis takes a lot to get that stuff out. It may take a half hour just to clean one of those brackets - then when the brake hose clips crumbled, crap, now I need those stupid clips and don't have any. I knew the sway bar links were toast - but the brackets that hold the sway bar to the frame are messed up, too - one looks like it hit something and the other is badly pitted and decayed. Oddly enough the front frame rails seem fine. Some of these parts may take an hour each just for basic cleaning. Takes more time to clean and de-rust, de-scale and get them ready for service again than anything else. So now I have to find sway bar bushings, see if I can dig up better brackets, find and order those control arm "snubbers or bumpers or whatever....... can't get them locally or even rockauto so that must be an AMC vendor only thing. (and those are a pain to install later once the rest of the stuff is back in place because the bracket that holds them is under the upper control arm when the car is raised up) I bought a roll of the copper/nickel brake line and will be making all new brake lines for the car.... leaving nothing to chance there. And the most fun part - that bolt that broke off when trying to remove the left shock tower top - still need to get that taken care of. The bolts that held the control arm "bumper" or "snubber" bracket to the frame were totally unusable - rusty beyond my wanting to clean them up and plate them. Need to dig some of those up from somewhere. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: farna

Date Posted: Mar/16/2018 at 4:52am

|

There are left and right brackets, but they CAN be swapped side to side. What that does, however, is move the caliper from front to back (or vice versa). Have to keep bleeder on the top, you know. So the brackets are mounted the same no matter which side you're on. Doesn't matter if the caliper is in front or back braking wise -- forces are the same. So why swap side to side? For clearance. IIRC Hornet/Concord et al have the caliper to the rear. I had to move caliper to front to use disc brakes on my 63 American, and I'm pretty sure on the 63 Classic also. 66 and earlier cars not originally designed for disc brakes typically need the caliper to the front for clearance. I don't recall how 66 Classic/Ambo/Marlin brakes are installed though. They used a special hose and the thin Bendix solid rotors, so they may not have clearance issues. The Bendix four piston calipers are smaller in some dimensions (closer to rotor) than the big single piston calipers too. ------------- Frank Swygert |

Posted By: billd

Date Posted: Mar/16/2018 at 7:27am

|

These must be mounted as I have them - steering arm would stop caliper from mounting since it mounts using bottom front bolt and top rear bolt. It mounts diagonally and sticks out and up at the rear behind the upper ball joint There really was little choice with these big calipers and these specific brackets. Also - concord I have had caliper to front - likely because of how steering arm bolts on using lower front bolt and upper rear bolt meaning the steering arm would be sticking up and out there at the rear. No choice on that car, either. The only car I have with the brake caliper to the rear is the Eagle - and on that car the steering arm bolts on using the BOTTOM two bolts. It does not cross diagonally up across the back of the knuckle because there's an axle going through the knuckle. The steering arm bolts on the lower bolts below the axle and the caliper mounts to the rear of the upper ball joint and not in front like my other cars. I think you'll find that because the steering arm bolts diagonally lower front bolt upper rear bolt on most of these cars the caliper is to the front. I couldn't swap brackets and move the caliper back if I wanted to. You are correct in that they cannot be swapped side to side in the front because they are machined and cast a specific way. They are not symmetrical in that respect. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: Red Devil

Date Posted: Mar/16/2018 at 10:45am

|

Excellent attention to detail Bill. Very nice! If you could post the final thickness for your spindle flanges (in decimal, please) it would be much appreciated. IIRC, you said they started at 7/8" thick? Based on details from Wilwood for their kits that work with KH spindles, need to be around 3/4" thick, so with 0.100" removed must be in the ball-park. I'm sure it would help others looking for spindle options for Wilwood kits to know the flange thickness. Thanks,RD. |

Posted By: Lyle

Date Posted: Mar/16/2018 at 11:13am

|

A lot of the front and rear suspension "polymers and brackets" are the same as Mustang pieces. I don't know what the 73 suspension stop looks like but this one from Summit was identical for the 69 Javelin: https://www.summitracing.com/int/parts/bbk-2531/overview/ Mustang pieces are a lot more common and cheaper. If Summit has it then Rock Auto will likely. Here in the North we have far few parts suppliers so have to do more "strategic" searching for parts.

|

Posted By: billd

Date Posted: Mar/16/2018 at 4:45pm

|

RD- before I started I used a mic on them to get an exact measurement. I actually wrote it down! Yeah! I then machined some off of one, tried it, decided I wanted it better centered, took some more off - fit it again and it was great. So I took the final measurement of that one with a micrometer and did the other the same. So I have starting and final thickness written down. Lyle - I hear ya - it's almost that bad around Des Moines - oh there are part stores - but they only have really common later model stuff - and I mean REALLY later and REALLY common. I'm going to proceed with all the stuff I have and will have to order (via a vendor or RA or Amazon or whoever) the stops/bumpers/snubbers and the sway bar bushings (the ones that hold it to the frame) One bracket was bent as the car apparently hit something at some point or some idiot jacked it up there. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: amxess

Date Posted: Mar/16/2018 at 9:59pm

| Lookin good Bill! I went without the dust shields. 68-70 ones and the later ones you're getting didn't work with the Wilwood brakes. Maybe the KH ones would but can't find them. Brakes will cool better though! |

Posted By: billd

Date Posted: Mar/16/2018 at 10:10pm

|

Thanks. Apparently this has a large sway bar - I went to town AGAIN today for more parts and asked the about the sway bar bushings - and had taken one from that car with me. They didn't have anything with a hole that large and I don't mean worn out as it was snug on the bar so it must be the larger bar. I guess I have to actually measure the sway bar tomorrow and order the right bushings. The ones on the car aren't totally trashed - they should be changed but oddly enough aren't eaten up by the oil the car has leaked in the past like some of the other bushings. They seem pretty solid yet, actually. I'm really happy with the way the brakes have fit and gone into place. Doing a mock-up and dry run or two with a spindle and rotor and test fitting a caliper was the easiest part of the whole project - getting the old parts off like the upper control arms (those bolts are never easy to get out on these cars) and getting things cleaned up was far more work. And machining the spindles - piece of cake. I'm wondering if I should run the master cylinder with these until I get one for disks - the master cylinder was replaced only weeks before the car went up on stands a year ago - it's brand new. It's a drum brake master - so unless there's a bore difference, the only real difference would be the need to remove the residual check valve for the front circuit and to make really sure I kept watch on fluid since disk brake calipers hold a lot more fluid and take in more as the pads wear than drum brakes ever would. If the bore is the same then the forces would be the same, just a capacity difference. Keeping it full should work until I decide to get a new one. Hate to waste a brand new master cylinder. I guess I'll look up bore size perhaps from the Rockauto site...... -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: amxess

Date Posted: Mar/17/2018 at 8:12am

|

Is your sway bar stock or aftermarket? I've used poly sway bar bushings (and for strut rods) for years and swear by them. Won autocross class against new Mustangs/Camaros. Checked my 73 parts book. Master Cylinder has same part # for 74 Javelin with or without disk brakes,but doesn't list a 73 without disks.My 72 & earlier parts book has same part # for 69-71 Amx,Javelin WDB & 70-72 LDB has a different part #. My car sat for two years. Did have crud in master which I replaced. Had replaced lines previously with stainless. Used one whole bottle + 1/4 of another flushing lines until all clear and no air.. |

Posted By: Mopar_guy

Date Posted: Mar/17/2018 at 8:15am

I'm still running a drum brake master on mine 4 years after going to 4 wheel disc. As much as I drive it, I still haven't had to add fluid due to pad wear. IMO, use that new master you already have. ------------- " http://theamcforum.com/forum/hemilina_topic95889.html" rel="nofollow - Hemilina " My 1973, 5.7 Hemi swapped Javelin |

Posted By: farna

Date Posted: Mar/17/2018 at 8:29am

|

Most AMCs had the same 1" bore (or metric that is very close to 1" in late model Eagles) for all brakes. The exceptions are a 1-1/8" bore MC for the "Big Bendix" calipers (3.1" piston vs 2.6" -- 75-76 all, 75-78 big cars) and a 1-1/16" used with Kelsey-Hayes calipers for manual discs (K-H calipers have a 2-3/4" piston - 71-74). The Matador and Ambo used 1-1/8" MCs with K-H calipers and power brakes also (71-74). They used a bigger power booster than all other as well. So you will be fine with the drum MC with residual pressure valves removed from outlet to disc brakes. ------------- Frank Swygert |

Posted By: billd

Date Posted: Mar/17/2018 at 10:49am

|

You are all correct - you have validated my findings in that they all used 1" bore master. Funny thing - some parts sites show the same cylinder, some show with the larger reservoir for the disk than the drum, but they all have the same line sizes and same bore. And thanks for validating my plan - use this new master until it needs to be replaced. I bought a quart of fluid - coupled with what I have I'll be able to flush things well. Of course I'm replacing all of the lines - so there will be new lines along with the unused calipers and recent master. I have a roll of the copper/nickel line. Will be using that. Because it's a drum to disk conversion several of the lines will be quite different so some will be "from scratch". Thanks, Mopar_Guy - that's my plan. I had figured, based on experience and training but your REAL WORLD experience using the drum master helps. Stock sway bar and I've wondered about the poly bushings because they'd outlast the rubber under my conditions. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: farna

Date Posted: Mar/18/2018 at 7:23am

|

The sway bar is the only place I typically use poly bushings. Doesn't affect ride, and you put a sway bar on to stiffen against body roll anyway. Don't like the poly control arm or strut rod bushings on a street car -- too much vibration and shock transmitted to the car. I've used the drum master in several drum-to-disk conversions -- every one I've done with manual disks, and at least one (my car) with power (used drum booster and MC). Kept it until the booster failed and I retrofitted a newer booster (Ford Ranger). The 65 Rambler drum booster (and the Ranger booster) boost the brakes just enough to know you have some help, but still provide a good bit for pedal feedback, unlike the large boosters used in most mid 70s cars with disc/drum setups. ------------- Frank Swygert |

Posted By: billd

Date Posted: Mar/18/2018 at 8:51am

|

Frank I couldn't agree more. I will likely end up using poly for the sway bar bushings - like you say there's no road vibrations etc. transmitted there, and the rubber on the links absorb anything coming from the lower control arms. Your comment on the boosters reminds me of when I was in college for a few weeks I car-pooled with a neighbor girl who lived about two blocks from my parents and was going to the same school. When it was her turn to drive she had me drive her car- a Chrysler product (can't recall the exact model now but a 70s car) and I hated the power steering feel and the power brakes. NO road feel on either and talk about hair triggers...... ugh. I would have preferred MANUAL, no boost, no power, to the feel of the steering and brakes of her car. More work on the car today I HOPE......... Here are the bolts I de-rusted and cleaned up and plated - they hold the bracket that holds the lower control arm bumper bracket to the frame. They were totally rust before. Also the left strut rod - I refinished the nuts and large concave washers (or convex, depending on your point of view - I guess they are DISHED washers from either side!!) I also plated the threaded area to slow rust and make alignment easier.    -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: Red Devil

Date Posted: Mar/18/2018 at 9:15am

|

Hi Bill, Assume you're baking plated fasteners and structural parts after plating to minimize chance of hydrogen embrittlement stress fracture? Thanks, RD

|

Posted By: billd

Date Posted: Mar/18/2018 at 12:17pm

|

Been into many discussions and studies on that topic and the sort of plating I'm doing has no risks, the parts aren't subjected to the sort of acids involved - and frankly, even the professionals where I get the supplies say it's "more talk than problem". Somehow it got applied to all plating, all acids, any length of times and so on instead of where the real/only problems are. In other words, the info was grabbed from the web and took on a life of its own over time. The circumstances where it's a problem aren't present in my cases. In fact, in most cases of modern plating. (I know of no one baking plated parts.) A number of professional plating areas have debunked the need for this sort of plating and on the parts being done. A pH in the ranges I'm working with aren't an issue - and the zinc is applied so quickly the substrate below isn't exposed to the MILD acid for more than a split second. Ammonium chloride, potassium chloride, zinc chloride......... pH roughly 5.3 to 5.6 -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/18/2018 at 2:58pm

|

Does anyone have a good photo of exactly where the original/proper combo valve mounts on a 73 Javelin? I had to cut the lines to remove the original pressure differential switch, and I have a valve I went through and cleaned up and checked over.......... but want to put it where it should be or where the factory put it if at all possible. The TSM shows "sort of" but not enough detail to know how HIGH or how LOW on the inner fender it goes. I can tell that it goes as far back as practical - or at least the pic in the TSM appears that way......... Any good pictures of the combo valve placement? I assume two bolts - nuts to the wheel side or the engine side?  -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/18/2018 at 3:46pm

Only picture I could find so far. I am still looking. -------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: pit crew

Date Posted: Mar/18/2018 at 3:51pm

Ok, found this. 1974 but the same as 1973. Bolts on the inside. -------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: pit crew

Date Posted: Mar/18/2018 at 3:58pm

Ok, poor attempt at enlarging it. -------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/18/2018 at 4:01pm

|

AHA! I wondered - it seemed to me that the valve itself couldn't be level if the holes were level - because the holes in the valve are not even - the rear mounting hole is above the internal valves where the front is below. These photos show me that the valve isn't level, but the mounting holes appear to be. Still in my shop on the little chromebook but once I get to a larger computer I bet those will show me what I need. Thanks. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/18/2018 at 4:06pm

|

My pleasure Bill. Most of the Javelin pictures I have are from a 1974 car but the good news is the 1973 cars were almost identical. Close enough for government work as they say. Be happy to help out any way I can. Check the TSM on bleeding the brakes. The differential valve pin needs to be pull outwards, of course they had a J tool, while you are doing the bleeding. -------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/18/2018 at 8:33pm

|

Interesting to note that with the short line coming from the combo valve rear port and connecting to the main longer line to the rear brakes, AMC may have been able to use the same rear brake steel lines for disk and drum brake cars even though they used a different valve and location. That short line did two things - made it far more easy to connect the line to the rear - do it before mounting the valve, and then use the coupler to connect to the main rear line which still comes up in the same location at the firewall with either brake system. Clever - easier to connect, was able to use the same rear steel line. On the pin - that's the metering valve portion which restricts pressure to the front brakes until the pressure in the rear builds up to a certain point - this was supposedly to ensure the rear brake return springs had been overcome before the front brakes could receive pressure and apply. It's especially important using pressure tank type bleeding or certain other means as you'll get nothing to the fronts if there's not enough rear pressure. We used to have a small spring clip made for that purpose - it slipped over the pin as you squeezed it, and then once over the pin you release your finger pressure and it held the pin out so you could bleed - it opened the metering valve and held it open. I don't know what ever happened to that tool - I'll either buy or make one since I do this sort of thing enough anyway and was used to having that little spring clip tool handy in decades past. Bolt heads in the engine bay? Interesting - that puts the nuts and threaded portion in the wheel well - subjecting the nut and threads to salt, road spray, etc. Odd - but for factory assembly it does make sense - stick the bolts through the valve, then onto the fender and then the nuts are put on from the underside and tightened up. It was likely easier at the factory that way. Thanks for the photos, etc. - very helpful. Now I need to mark for and drill holes.......... I measured the sway bar at 15/16" - she's a large one. Now to order the bushings. Oh - left strut bracket painted up and reinstalled, new lock nuts, etc. and left strut in place with new bolts and nuts.  -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/19/2018 at 10:20am

|

Well it appears that AMC made two small "dimples" or dents where the holes would be for mounting the combination valve for front disk brakes. Once I got the old pressure differential switch out of the way and cleaned things up down there, removed the old line to the right front wheel, etc. I found two small very well made dings about where Pit Crew showed the valve may mount. I stuck a couple of long sheet metal screws through the holes in the valve just so I could hold it up and look to see where the ends of those screws lined up and - nice - the screw tips touched the dimples dead-center and with the valve pretty much were the pictures showed it should be. Ah, but they are made to be drilled from the ENGINE SIDE- UGH, I don't have a teeny little drill that will fit down in there or a right-angle drill to get between the inner fenders and the engine/headers to drill. So I'll see if I can get my Dremel down in there and at least make eighth inch holes so I can see from the OTHER side where to drill. The dimples don't show through the under coating and stuff on the wheel side. So wish me luck - if I can work a Dremel in there even with the flex shaft I'll drill where those two pings are so I can tell where to drill from the other side. Then on to starting to make and run brake lines while the paint dries on a couple of other parts for the left side. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: Lyle

Date Posted: Mar/19/2018 at 11:04am

|

If the dremel is not going to work out but you have a little room for a hammer swing there is another method. Those hard, short, blue, furniture tacks - hold them with a pair of needle nose pliers and try piercing the sheet metal. Those little suckers are hard and sharp. Usually doesn't take much to pierce sheet metal with those. Have even pushed them through with a block of wood and a pry bar - more coordination required - like that third had we were suppose to be born with. A right angle drill, and here I thought you had everything:) Good luck, looks good.

|

Posted By: pit crew

Date Posted: Mar/19/2018 at 11:26am

What is it with those darn engines always getting in the way?

-------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/19/2018 at 12:11pm

|

The sheet metal there was amazingly stout (and thick compared to some areas) A Dremel itself didn't work too well - but with the flex shaft, it worked fine. (by the way, not enough room for a hammer swing, really...... headers, head, etc.) Still not able to get a perfectly straight shot at the front hole - but enough I can now drill to the 5//16" needed from the other side. As you may notice - I really need to get a HEATER in this thing. I have a core but have no heater valve or anything else. Not sure what condition the other heater parts are in but the core is obviously toast as you may notice in this pic........ While removing the original pressure differential switch, the lines were REALLY stuck, so I used a cutting wheel in the Dremel and sliced the lines - and in the process the screw that holds the switch to the firewall pulled out - the sheet metal wasn't really strong there and/or the hole had been stripped. There's some paper towels down there to catch and fluid that came out of the lines and such but I had sucked the fluid out of the master and the front lines have been open for a year so nothing really came out to worry about. I really hope this combo valve I have doesn't LEAK and that it works after I rebuilt it! Once in, don't want to ever have to remove it again.   -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/19/2018 at 12:39pm

Bill, I don't know if you have had the joy/luck of taking apart the dash of a big body Javelin yet but it is the most fun thing you will ever do. You are in for a real treat when it comes to changing out a heater core. If I can offer up any help/tips I'll be glad to help. I have worked on way too many of them. -------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/19/2018 at 5:08pm

|

I always thought that the Eagles had the worst possible dash to work with........... those are a royal pain, it's extremely tight running wires and cables through the radio pod area and it's just a nightmare. Maybe I can leave the 73 with you since you are very experienced with these? I want to add a decent radio, swap out the cluster, etc. (I also want to add AC to the car but can't find a complete setup from another car so that may not happen any time soon) Some of the brake line fittings aren't very good - I tried to buy new but they said "not stocked but we can get them.........." Geesh. There are also, what, three or four different sizes of nuts used? So I dug through my stashes of brake parts and fittings and found a few I have saved from other projects and a few I inherited when I got some tools and stuff from a former boss. I cleaned up a bunch that were decent but had a bit of rust or imperfections and plated them today while putting the upper control arm and spring on the left side. It's taking forever but it's getting there. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/19/2018 at 9:32pm

The biggest problem with the 71-74 Javelin dash is how much you have to disassemble just to get at simple things. For example you have to remove the entire dash pad to change out or add a radio. To get the dash pad off you have to remove the passenger side trim and grab handle. Not to mention the hidden stud up behind the map light. The speaker grill cut out in the dash makes the dash pad substructure very weak and prone to major cracking. As far as a radio, I have installed RetroSound radios in a number of AMC cars with excellent results. When you get to that stage feel free to reach out for information. -------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: farna

Date Posted: Mar/20/2018 at 5:10am

|

Now if you only had a six, you'd have a little more room to work under the hood...at least in a Javelin. Still rather snug in the Eagle... How committed are you to keeping this car all stock? Since it didn't come with factory AC I'd consider a Vintage Air or Southern Air unit. They are usually a bit more efficient than the old ones. You'd still need the dash vents and maybe controls (you can connect the aftermarket AC with the original controls... not the cables, either new cables or short cables to electric or vacuum switches). I like the Southern Air products a bit better... but maybe because they are made here in SC... http://www.southernrods.com/a-c-and-heat-components/" rel="nofollow - https://www.southernrods.com/a-c-and-heat-components/ ------------- Frank Swygert |

Posted By: billd

Date Posted: Mar/20/2018 at 5:01pm

|

I do want to stick with correct AC stuff if possible - say if someone is parting out a Javelin with AC. I have a good aluminum bracket as originally used, and don't really want to go the route of having to spend for brand new system - especially if I still would need to modify the dash and install the duct anyway. I have the ducts that go in the dash - found those cheap at a swap/show. I'd need to get the controls either way anyway - so there's no savings there. I prefer to integrate into the car and feel the best way is to find someone who stripped the AC out of a race car or something like that. I know I'd need some new parts even with original type AC. Anyway, got the drag link and idler arm, dropped today so will start working on the steering linkage. Man the grease was so built up and caked on I had to scrape just to find the nuts to get a socket on. I guess I should be glad that prevented rust! HA. The steering won't be too bad - the drag link will be soaked and cleaned up and with all new tie rods and sleeves and clamps it will go back together more easily. All that's left with the brakes is running the new lines. I hope that combo valve works and doesn't leak - maybe I should look for a spare just in case....... The left side is together save for shocks - which I need to find in my stash or BUY. Mounted the combo valve and ran the short line to the right front wheel. STILL need to get that broken shock tower bolt out of the left side - that will be one of the hardest parts of the whole project, perhaps. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/20/2018 at 5:37pm

http://www.summitracing.com/parts/clp-pv-2/overview/" rel="nofollow - http://www.summitracing.com/parts/clp-pv-2/overview/ -------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/20/2018 at 5:48pm

|

And are they also shaped differently, meaning re-doing the lines - again.........? It appears the line nut sizes could be different but I've not directly compared. We'll see what happens, how things go. I'm hoping the cast original I got works out. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: pit crew

Date Posted: Mar/20/2018 at 5:52pm

-------------  73 Hornet - 401EFI - THM400 - Twin Grip 20 |

Posted By: billd

Date Posted: Mar/20/2018 at 5:55pm

|

Well if they are a drop-in perfect fit with the same fittings, that's different. Yeah, thanks - they could be a good plan B. I could also beat on one with a hammer a bit - rough it up and then paint it with hammered paint.... LOL Make it appear to be cast iron -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: purple72Gremlin

Date Posted: Mar/20/2018 at 6:06pm

| I swapped 1978 concord disc brakes on my 72 Gremlin. completely rebuilt the front end while I was at it. only thing I didnt do was the spring mounts couldnt find better ones. when I get back to working on it, going to fix that and change the front springs as they are too STIFF. want to replace the rear springs as well. and redo all the brake lines again. ( they were functional, but looked terrible) |

Posted By: billd

Date Posted: Mar/20/2018 at 6:51pm

|

The springs I bought for the front of my SX4 are WAY too stiff - don't know what they did but the wire is too large and even a bit of a pavement bump hammers the car harder than it should. So when I get time - going to put different springs under it. I rebuilt the spring supports when I did the front end on the Eagle. The springs I put in my 73 came from a 73 Javelin so should be fine. Found out why the car had those twist-in spring spacers when I got it - there was a broken front spring. It's a wonder the thing stayed in place they way they had it. It should sit better when done and all new bushings will help stop the constant banging and hammering sound with every bump. Man a rough road was noisy before.   -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: billd

Date Posted: Mar/21/2018 at 4:29pm

|

Now before anyone says anything - I KNOW the idler arm is on the bracket incorrectly - but if you also note the washers and nut are NOT on it - it's just slid together to get an idea of how it fit after nickel plating the bracket (and to see how it might look with part plated and part painted. I know it goes the other way because the drag link goes behind the idler........ Anyway I got the steering linkage cleaned, some more plating and some stuff simply got painted. I was tempted to do some powder coating but that's more messy and time consuming and this isn't a show car..... I plated the washer and nut for the idler arm, did the bracket in nickel, painted the arm and replaced the bushing. I put the tie rods together to the length I measured the old ones before I dropped them out of the car - it will at lease be sort of close. I refinished the idler arm bolts and nuts as well as the spacer that goes between the idler bracket and frame rail at the bottom. Hopefully the rest won't take so long as this part has so far........ except for the new brake lines and I expect a few hours for that at least. Ugh - getting too old for that up and down, under and up again.   -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: purple72Gremlin

Date Posted: Mar/21/2018 at 5:05pm

| The up down up down....is why I now have a lift...... |

Posted By: Mopar_guy

Date Posted: Mar/21/2018 at 6:51pm

Me too. I can get down on the floor OK but getting back up is a whole other story...  ------------- " http://theamcforum.com/forum/hemilina_topic95889.html" rel="nofollow - Hemilina " My 1973, 5.7 Hemi swapped Javelin |

Posted By: billd

Date Posted: Mar/22/2018 at 6:59am

|