Stock 360 output

Printed From: TheAMCForum.com

Category: Competition

Forum Name: Drag Racing

Forum Description: Your latest numbers, events you attended and more

URL: https://theamcforum.com/forum/forum_posts.asp?TID=91270

Printed Date: Apr/16/2024 at 5:30am

Software Version: Web Wiz Forums 12.03 - http://www.webwizforums.com

Topic: Stock 360 output

Posted By: WesternRed

Subject: Stock 360 output

Date Posted: Dec/06/2017 at 1:54am

|

Just curious about the figures for 71 vs 72 360 4 barrel engines, both are said to have 8.5 compression. 71 285 HP @ 4800 Gross 72 195 HP @ 4400 Net I'm well aware that the rating system changed from gross to net HP, which accounts for most of the HP difference. I'm more interested in the accompanying drop in RPM at the peak. Do the accessories suck that much horsepower at high RPM that the peak RPM drops or are there other factors at play. I'm trying to figure out what I can expect out of the 360 in my Gremlin which as far as I know is a 71 4 barrel engine and I expect fairly stock other than a performer intake. Presumably some horsepower's have also escaped the stable over the years. I really don't have any history on the motor other than it came out of my 71 P Code AMX. It's hooked up to a 727 via a custom convertor (flat crank engine) and I have an AMC 20 with 4.1 gears in the rear. Ran at the strip last week with 24.5" tyres and had 88 mph across the line, which works out to be roughly 5000 RPM (didn't have a tacho in the car at the time). Accessories at the moment are the alternator, water pump and factory flex fan. Based on the 72 peak at 4400 RPM, I'm probably pushing it well beyond optimum RPM. Heading back tonight with some 26" slicks on the back, which should help with traction and bring the terminal RPMs down a little, so I will have some more data shortly. Just trying to gauge what would be reasonable to expect from this combo to know if I am on the right track. |

Replies:

Posted By: WesternRed

Date Posted: Dec/06/2017 at 8:28am

|

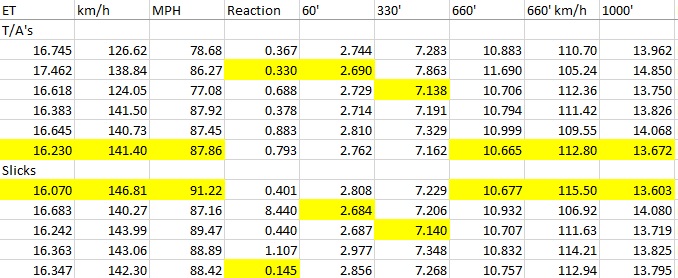

Update with the 26" slicks, I am crossing the line at just short of 5000 RPM on the newly installed tacho as expected. The best ET was 16.07 @ 91.22 MPH, race weight with driver was 3073. Biggest problem is 60' times in the 2.6-2.8 second range, not exactly what I would have expected from 4.10 gears, it's just got nothing off the line, so I'm assuming I have a problem somewhere. |

Posted By: Sonic Silver

Date Posted: Dec/06/2017 at 8:50am

|

Posted By: WesternRed

Date Posted: Dec/06/2017 at 4:37pm

|

Well that makes sense, presumably that is choking off peak RPM too. My mph suggests around 180 horses are still in the barn. Now I just have to figure out why I can’t get it off the line. Convertir problem perhaps, it’s a bit of an unknown, foot on the brake it will rev to around 1500. |

Posted By: Sonic Silver

Date Posted: Dec/06/2017 at 6:44pm

|

One thing that I noticed in old car magazine tests from the 1970 era was that I remember 2 or possibly 3 tests of AMC's with 3.91 gears.

The first was a 70 Javelin SST 360- 4 speed in Car Life magazine that ran a 15.46 at 91.09 mph. The 2nd was a 73 Jav/AMX with a 401/4 speed that ran a 15.4 at 92 mph. I believe the magazine was Road Test. The 3rd (also Road Test Magazine I think) was a Rebel Machine with a 4 speed, and I am pretty sure it had 3.91 gears. I don't remember the exact times, but it seems like it ran mid/high 14's at about 92 . I don't remember ever seeing a magazine test with a good 1/4 mile time or mph out of a factory stock AMC car with high numerical gears. I realize it was just 3 tests, and driver, track conditions, weather, altitude, etc. make a significant difference. Popular Hot Rodding tested a 70 AMX with a 360 /4 speed and 3.54 posi. They said that their best times (14.90 at 94.63 mph) came by shifting early to where the rpm dropped back to the point where it made peak torque (around 3,300-3400 rpm). They dropped their times down by shifting out of 1st and 2nd at 4,200 rpm, and shifting from 3rd to 4th at 4,500 rpm. The rpm would drop back about 20% from 1st to 2nd and 2nd to 3rd, and about 25% from 3rd to 4th. Remember, these cars were all factory stock with exhaust manifolds, stock cam, tires, carb, exhaust, smog, etc. in all these tests. |

Posted By: xtrememotorworks

Date Posted: Dec/06/2017 at 7:06pm

|

That 60ft is killing you, my wifes 5.0 with some 2.73 is slow with a 2.19. is it falling on its face? Cutting out? ------------- Xtreme Motorworks 425-222-0030 xmrinc.com http://www.facebook.com/XtremeMotorworks https://www.facebook.com/groups/AmcRamblerPerformance/ |

Posted By: xtrememotorworks

Date Posted: Dec/06/2017 at 7:19pm

------------- Xtreme Motorworks 425-222-0030 xmrinc.com http://www.facebook.com/XtremeMotorworks https://www.facebook.com/groups/AmcRamblerPerformance/ |

Posted By: Sonic Silver

Date Posted: Dec/06/2017 at 7:47pm

|

Posted By: WesternRed

Date Posted: Dec/06/2017 at 8:46pm

|

I doesn't seem to stumble off the line, not spinning the tyres either, it's more like taking off with the handbrake on, just seems to take a while to wind up. Based on your road test numbers Sonic, I should still be well into the 15's if not 14's with the lighter Gremlin body. |

Posted By: Sonic Silver

Date Posted: Dec/06/2017 at 8:59pm

|

Posted By: WesternRed

Date Posted: Dec/07/2017 at 12:35am

|

So where is the best place to start with this? I'm thinking it has to be either be tuning, convertor or transmission related. I also have a rear main leak that I will have to deal with. Would ideally like to correctly diagnose the problem, then pull it apart if necessary to fix it. It's running a 600 vacuum secondary carb, which is probably not an ideal long term solutions and a relatively stock stall is probably not ideal either. |

Posted By: WesternRed

Date Posted: Dec/07/2017 at 2:23am

|

Posted By: WesternRed

Date Posted: Dec/07/2017 at 8:05am

|

Went over some of the basics tonight, seems like I had the initial timing set at 5 degrees and I have about 15 degrees of mechanical advance for 20 total, this was with the vacuum advance disconnected, I've bumped the initial up to 15, which gives me 30 total. I didn't have the vacuum advance connected the first night, but did the second time out, couldn't quite verify what it was doing though. Also checked manifold vacuum was 18 in/hg at idle in neutral and dropped down to 10 idling in drive. From about 1 turn out of the idle mixture screws, there is no appreciable increase in idle speed or vacuum. I would also like to run a compression check just to see if the numbers are reasonable. If I do need to change the convertor and/or rear main seal, then it could be a good opportunity to bump up the cam while I'm at it, assuming the motor is reasonably healthy. |

Posted By: WesternRed

Date Posted: Dec/07/2017 at 7:00pm

Pics from the strip, got the look, just need to go faster   |

Posted By: wantajav

Date Posted: Dec/07/2017 at 8:00pm

|

Nice Gremlin. ---Are you sure the throttle plate is opening all the way with foot to the floor? (adjust cable/linkage) ---getting enough fuel squirt from the accelerator pump? ---what kind of engine vacuum are you getting (inches and how does the needle behave as you rev it) ---maybe you have a flat cam lobe or loose timing chain (retards valve timing =kills low end power) ---leak down test might be a good thing to try

|

Posted By: WesternRed

Date Posted: Dec/07/2017 at 9:39pm

|

Thanks for the ideas. ---Are you sure the throttle plate is opening all the way with foot to the floor? (adjust cable/linkage) Yes, but it's a vacuum secondary carby, so I should verify that the secondaries are opening, pretty sure they are. ---getting enough fuel squirt from the accelerator pump? I am getting a shot from the accelerator pump, couldn't tell you if it is enough though. I did back the adjustment off on the linkage since it was a bit tight (partly depressed at zero throttle), but didn't notice any difference in performance ---what kind of engine vacuum are you getting (inches and how does the needle behave as you rev it) Vacuum at idle numbers are above, 18 idling in neutral, 10 idling in drive, need to make some more observations here by the looks of it. ---maybe you have a flat cam lobe or loose timing chain (retards valve timing =kills low end power) I did change the timing chain but only for another better used one, flat cam is also a possibility, I don't really have any history on the engine other than it was a runner. MPH suggests it is making reasonable power for a stocker. ---leak down test might be a good thing to try Yes, should probably do that as well as a compression test. Basically I didn't want to get bogged down in needing to rebuild the engine, so just wanted to run it as is. If it's ok, I can just live with some minor upgrades like a carby and cam change with the prospect of building a good motor sometime in the future. My thoughts would be to run a Comp 280H or similar and add a decent amount of stall to the convertor. |

Posted By: pfordamx

Date Posted: Dec/07/2017 at 10:30pm

| in highschool i would bracker race our 1968 ambassador 4door stock converter stock 2.90 gears with a low compression 343 with comp 280h cam, r4b, 1 5/8s hookers and a malory unilite dizzy it would run 15.70s at 90 with around a 2.2 60ft no slicks just open legged stock axle. i was always curious what that combo would've done in a gremlin or hornet with a decent gear. |

Posted By: pfordamx

Date Posted: Dec/07/2017 at 10:32pm

| i would check you ignition advance and make sure you've got 38ish degrees as soon as possible. |

Posted By: WesternRed

Date Posted: Dec/07/2017 at 11:05pm

| Well, I've now got 10 degrees more than I had previously, but haven't had the opportunity to road test it yet. |

Posted By: wantajav

Date Posted: Dec/08/2017 at 8:51am

| I also meant to mention - how's the balancer? I wonder if it slipped and you aren't getting the right timing mark anymore. |

Posted By: WesternRed

Date Posted: Dec/08/2017 at 10:14am

| Probably another good thing to verify. |

Posted By: tached_out

Date Posted: Dec/09/2017 at 2:07am

|

I can tell you right now your lack of spark advance is killing HP at the starting line and all the way down the track. Your distributor should go to full advance (around 38 degrees) and stay there as soon as the engine starts. I ran a 360 powered 3,000 pound (with driver) Gremlin for several years. My combo wasn't that much different to your's. I got a best of 11.36 @ 120 mph. 60' times were 1.5 seconds. I ran a single point distributor with Accell racing points and an Accell Super Coil. Here's what I did to the distributor. I removed the vacuum advance unit and locked the plate in place with a small bolt and nut. You can accomplish the same thing by simply disconnecting it and leaving it in place. I made myself a set of super weak advance springs from a ballpoint pen. The springs were just strong enough to hold the weights in while the engine was stopped and while it was cranking. As soon as it fired, The weights went to full advance. 36 degrees worked best for me. Don't worry what you have at idle, just concern yourself with the total which you can observe with a light as soon as it's running. You should see mid 12s @ 110 mph once you get this thing working.

|

Posted By: RUMBLR

Date Posted: Dec/09/2017 at 6:31pm

|

Yes put more advance in it - timing makes so much of a difference. The vacuum advance wont make any difference going down the strip. I was running 18 initial and 18 mechanical total 36 - but easy to adjust with the MSD dizzy. ------------- 343 904 M20 - 11.83@115 |

Posted By: 304-dude

Date Posted: Dec/09/2017 at 6:55pm

|

Haven't kept up ip on the thread, and just noticed your link on the new post you made. Stock spring are good up to 4500 RPM and start to float. Discovered after dropping a valve in my 304 back in 90. The stock high compression 70 390 heads had just as weak springs. Obtain a better spring to keep your usable torque curve stable up to 6000 RPM. I assume no more than 40 lbs over stock spring rate. ------------- 71 Javelin SST body 390 69 crank, 70 block & heads NASCAR SB2 rods & pistons 78 Jeep TH400 w/ 2.76 Low 50/50 Ford-AMC Suspension 79 F150 rear & 8.8 axles Ford Racing 3.25 gears & 9" /w Detroit locker |

Posted By: WesternRed

Date Posted: Dec/10/2017 at 2:14am

|

Looks like timing needs some more work, wish I had thought to play with that at the strip last week, I had the timing light with me. I certainly wasn’t looking to rev it past 5K as I, but managed to shift a bit late a couple of times to discover the limits of the valve springs. What was done to yours for those sort of times teached-out? |

Posted By: 70amcpwr

Date Posted: Dec/10/2017 at 9:21am

|

Timing is #1. Make sure fuel octane is good enough for the advanced timing though, 38* is best, I've run into the 40's w/my 70Javelins slightly modified 360 but detonation becomes an issue. Didn't catch if the 600 was Edelbrock or Holley. Assuming Holley, your accelerator pump adjusters spring controls the length of time the fuel continues to squirt, the wider the coils on the spring the longer the time of the squirt. just make sure there's 0 play between the screw head and arm, sometimes bending the linkage is needed to accomplish this. You should be able to make the secondaries fully open by removing the air cleaner, w/motor running manually give the carb wide open throttle while covering the primaries w/your hand @ the same time, that's true for Edelbrock also. After messing w/the running adjustments I'd go back to the smaller tires myself and just watch your RPM's. I question the 4.11 combination w/the big tires and the gearing in the 727. Even though it sounds like the gearing justifies the tire size without the torque it's not getting the tires rolling fast enough. There's a lot more qualified members than me @ this but logic tells me all stock gearing w/stock tires gave you a 1:1 ratio, 100mph @ 5000 rpms, you should easily be able to accomplish that in a 1/4 mile with the modifications you're making. Good luck and have fun! ------------- 70amcpwr You just can't fix stupid. SOLD 1970 BBO Javelin, wifes 73 AMX 360 4spd. Next project 1969 AMX |

Posted By: WesternRed

Date Posted: Dec/10/2017 at 8:06pm

| I’m thinking there would be a lot to gain by putting a decent converter in it to make better use of the slicks. 26” is a pretty small diameter as far as slicks go, but 10” is definitely way overkill for this car, looks good though. |

Posted By: PROSTOCKTOM

Date Posted: Dec/10/2017 at 9:21pm

|

Have you looked at your brakes, hub bearings, axle bearings? I had a friend that had a couple tight bearings and the car picked up a bunch once that was corrected. Easy enough to jack up the car and check. Tom

|

Posted By: 70amcpwr

Date Posted: Dec/10/2017 at 9:56pm

I hadn't checked the conversion, your right it's only .7" larger diameter than 225/60 14. Still believe though it's effecting your time off the line. My Javelin hooked up well w/225/60 14 T/A's (obviously not drag tires just talking size), just the right amount of spin if you wanted and would hit second (Borg Warner M11) real hard, would do more than chirp the tires, never ran any times though. ------------- 70amcpwr You just can't fix stupid. SOLD 1970 BBO Javelin, wifes 73 AMX 360 4spd. Next project 1969 AMX |

Posted By: tached_out

Date Posted: Dec/11/2017 at 6:43pm

All my times were from Mission Raceway Park in British Columbia. 200' elevation. I ran a 360 from a `72 Wagoneer. -343 cast pistons. -Stock rods with ARP bolts. -Stock heads with 3 angle valve job, mild bowl cleanup, port match and Crane 99839 single springs. -Comp 280H cam. -Torker intake. -Carter 625 emissions calibrated carburetor. -Hooker headers. -Single point distributer with Accell HD points and Super Coil. -904 Torqueflite with 10'' converter. -Mopar 8 3/4'' rear with 3.91 gears. -MT 26x8.5 E/T Drags. -Lakewood drag shocks on front. -Car was 3,000 pounds with me in it. This varied by a couple of pounds depending on coffee intake. I would stage the car in drive and at an idle, then whack the gas on the second yellow. It typically ran an 11.60 in the morning right off the trailer. In the afternoon I'd run an 11.72 or so. I'd always dial 11.75 for eliminations and leave it for the rest of the day. I only remember changing it a couple of times. I always let the car auto shift in the burnout box and going down the track. It shifted into second at 4,800 rpm and into third at 5,000. Kind of a boring ride with nothing else to do, but it was dead nuts consistent. One cool October morning it ran a 11.53 then an 11.50 an hour later. I didn't have a weather station but the word was the air was exceptionally good, like about 1,000' below sea level. I decided to do something I had never done before because I was running the stock column shifter. I did my burnout as usual, but I staged in 1st and wound it out to about 5,800rpm and carefully bumped it up into 2nd. Then at 6,000rpm I bumped it into third. It liked it. That's the run I got 11.36 @ 120mph. The 1/8th mile numbers were 7.20 @ 97mph. Also the best numbers it ever ran. I sold the car so I could move my family to a nice quiet seaside community. To this day I wonder what it would have run like with a bigger carb and a good shifter. Sorry for the long winded answer. I was feeling nostalgic and couldn't stop typing. |

Posted By: WesternRed

Date Posted: Dec/11/2017 at 7:55pm

|

Long winded answers are good because that sort of information really helps. Assuming you are talking 343 flat top pistons, that would certainly add some compression. I've been thinking along the lines of the 280H myself, but not sure how it will go with the stock compression as I'd rather not pull the heads and have it turn into a full rebuild. Comp says the 280H is good for 9:1 compression with 2500 stall so stock 8.5:1 is not too far off. Carb by the way is a 600 Holley with vacuum secondaries, not exactly a performance carb, just what I had laying around. Did have it on my Javelin in the early days though, it could get 2.4 over the 60' with a lower than stock compression 343 and 2.87 gears, so I sort of think it's not the limiting factor on the Gremlin at the current level. I did back off the rear brakes because I thought they might be dragging so I think that's ok. |

Posted By: 70amcpwr

Date Posted: Dec/11/2017 at 8:15pm

|

Just for fun and the ease of doing it try some smaller and narrow tires. ------------- 70amcpwr You just can't fix stupid. SOLD 1970 BBO Javelin, wifes 73 AMX 360 4spd. Next project 1969 AMX |

Posted By: tached_out

Date Posted: Dec/11/2017 at 9:56pm

|

Aside from the spark advance that we already mentioned; The Performer is kind of ok for a basically stock street driven engine, but it isn't even close to being a racing manifold. It's been argued that it isn't even as good as the stock iron intake, but it's a lot lighter. Any performance increase would likely be as a result of that. The 600 is too small period. If it's on a Performer without a 1'' open spacer, it's way too small. Get a Torker with a 650 double pumper if you can. Run the intake with the exhaust heat. Yes, even at the track. The 280H is an amazing cam. Yes it would like a bit more compression, but 8.5 isn't going to make it a turd. It really needs about that much cam. The 4.10 gears will help a lot with offsetting your lack of cr. |

Posted By: WesternRed

Date Posted: Dec/11/2017 at 11:43pm

|

The Performer is just what was on the motor bit like the Holley is just what I had a the time. I do have a spare Torker, but I do think I need to be making a little bit more power to justify putting it on. I am in a bit of a dilemma with what to do on the induction side, I'm pretty keen on the Holley Sniper system at the moment since that would theoretically have some additional benefits as far a tuning and data logging goes, but obviously there is a fair bit of cost involved in going down that path. |

Posted By: tached_out

Date Posted: Dec/12/2017 at 1:02am

| That's my point. The Torker and more carb will make more power. |

Posted By: WesternRed

Date Posted: Dec/12/2017 at 1:43am

| I can see where you are coming from, but presumably that would only be the case if I also upgrade the cam and valvetrain to support more RPM. |

Posted By: nda racer

Date Posted: Dec/12/2017 at 1:47pm

|

Exactly, factory cam isn't going to cut it. 4.10 gear and shortish tires aren't going to help with a stock cam either. I've watched a car with "too much" gear slow it down in the 60 foot times... Do you have the stock spring in the secondaries in that carb? Also, is it a restrictor or a check ball in the diaphragm housing? I just question how quick the are opening. Also what shape is this engine in, due for a rebuild, any vaccuum leaks, etc. If you're going to stick with the 4.10s, time for a cam and make sure everything is good in there. Edited for clarifying "60's" as in 60 foot times. |

Posted By: Lucas660

Date Posted: Dec/12/2017 at 4:40pm

| I have a bunch of secondary springs if you want to play around with that Western, PM me if you are interested. |

Posted By: Sonic Silver

Date Posted: Dec/12/2017 at 6:43pm

|

Posted By: WesternRed

Date Posted: Dec/12/2017 at 8:00pm

|

Carb tuning is not my forte, that's why I was leaning towards the Sniper. The car is still very much a work in progress and then initial focus was just to get it up an running without spending too much money. Engine condition is a bit of an unknown, so the plan there was to see how it did run and if it was ok, then look at some bolt on changes like cam, carb and intake. Unlike the usual approach, the car is being built from the back towards the front. The only usable part of the AMC 20 that I had was the housing and brakes plus some Moser axles that I'd originally bought for something else. A truetrac centre and the 4.10 gears were added to this as it seemed like the way to go for something that was not going to be street driven. I'm a bit surprised that the 4.10 gears would be a hindrance with a low powered car other than running out of steam at the end of the strip, which was anticipated. But if that is the case than I will have to live with it until I can upgrade other areas to match. There is more money in the rear end than the rest of the car at the moment. |

Posted By: 70amcpwr

Date Posted: Dec/12/2017 at 8:15pm

|

Simply the 4.10 won't allow 100mph unless you rev passed 5k rpm's which will require valve train changes @ a minimum and should include a complete engine overhaul to prevent it from exploding in the event of a worn internal component. The take off is carb and intake, first gear ratio, tires, and maybe torque converter as mentioned. Don't be concerned w/learning how to work w/ a carburetor. Just do one adjustment/change @ a time and record the results. ------------- 70amcpwr You just can't fix stupid. SOLD 1970 BBO Javelin, wifes 73 AMX 360 4spd. Next project 1969 AMX |

Posted By: WesternRed

Date Posted: Dec/12/2017 at 9:46pm

|

A complete engine overhaul would run to $10K+ in Australia, that's why I don't want to go there. Stock cast rods would probably be the limiting factor once valve train is addressed I guess. 5000 RPM across the finish line would get me around 94 mph with the current setup, so I'm not too far off there, 5,500 will take me up to 104 mph, which will need more power. At the moment it's all about improving the 60' time from 2.7-2.8 or so down to under 2.0 or better which will improve the ET considerably. Even the 600 Holley should get me off the line if it's tuned properly. |

Posted By: amxdreamer

Date Posted: Dec/13/2017 at 12:10pm

|

My basically stock 360 in my 70 AMX (built with TachedOut) ran a 14.3 @96mph with a 2.87 rear. Stock with freeflowmanifolds, 2 1/2" duals with magnaflows, performer and a holley 670 vacuum secondary. ------------- Tony Vancouver, BC 1970 AMX 1972 Badassador AMO#10333 |

Posted By: Sonic Silver

Date Posted: Dec/13/2017 at 12:41pm

The stock cams are similar between the two, The Chevy engine hits peak horsepower at 4,100 rpm, and is basically flat from 4,000 to 4,600 rpm. The torque peak is at 3,700 rpm, and drops off pretty rapidly after 3,900 rpm. If you hit the traps at 91, you are turning around 4,800 rpm???

|

Posted By: tached_out

Date Posted: Dec/13/2017 at 4:50pm

|

I hope with all the advice flying around you don't forget the easiest (at this point) thing to address, your spark advance. I'll disagree with a couple of things suggested. First. The gear ratio isn't hurting you get off the starting line. It can't possibly. It's torque multiplication. This is basic physics. The lazy 60' times point directly at your tune up. These times would be even worse with less gear. Sure it is going to require you to look into your combination in the future. When you get the car sorted out you will need a more stable valve train and better rod bolts. You've spent the money on the rear end. Unless you want to spend a bunch more, leave it and work with what needs improvement. Second. Gremlins are not traction challenged. At 96'' wheel base, they are the kings of weight transfer. The key to making any car faster is to; 1- Get the most air and fuel into the cylinder during the intake event. This can only result in greater cylinder pressure. If you want to keep your 600 put it on the Torker. It's too small on a Performer and a Performer is too small on your engine. 2- Light the mixture at a time when the peak pressure of combustion will impart the greatest force on the crankshaft. In your case this is occurring way too late. All the pressure and heat that should move the piston down the cylinder and you down the track is going out your open exhaust valve. It's kind of like starting off on a bicycle with the pedal already too far down. You can address these two issues for the price of an intake manifold gasket. If you only want to take one step at a time, fix your timing.

|

Posted By: Sonic Silver

Date Posted: Dec/13/2017 at 5:17pm

|

Posted By: tached_out

Date Posted: Dec/13/2017 at 5:31pm

|

Oh! I know what you mean. I can tell you from first hand experience, Gremlins and AMXs require a great deal of respect when their wheels are spinning. They are not the least bit forgiving if you let the rump end get out from behind the front wheels.

|

Posted By: Sonic Silver

Date Posted: Dec/13/2017 at 5:39pm

|

Posted By: WesternRed

Date Posted: Dec/13/2017 at 5:43pm

|

Timing is definitely first cab off the rank, then I can run it at the strip again next Wednesday night to measure any improvement. I can try a few things with ther carby too, if I have some direction to go in. I do have an open spacer that I could run if needed. Traction is certainly not an issue with the slicks and the pictures from the strip do show a good bit of weight transfer. I do have a few things to address like the rear main seal and a small coolant leak on the intake, so that would open up the opportunity to make some other changes. The comverter is my other main concern, like the gears it should be a torque multiplier, but if it’s too tight then it could be working against me. It should really run in the 14’s as is and even faster with the right induction, cam and converter Anyway, let’s see what difference the timing makes first. |

Posted By: scott

Date Posted: Dec/14/2017 at 4:01pm

| Call me crazy if you like, but I have to ask: Is it starting out in second gear, & not first, for some reason? |

Posted By: Sonic Silver

Date Posted: Dec/14/2017 at 5:01pm

|

Posted By: WesternRed

Date Posted: Dec/14/2017 at 10:27pm

| I am getting all gears, but the factory shifter certainly makes things a little interesting. |

Posted By: WesternRed

Date Posted: Dec/15/2017 at 6:31am

|

Spoke to the local performance converter shop today and they didn't think changing the converter at this point in time was a good idea. Considering they charge $1,300 (Aussie dollars)for a good converter, they suggested upgrading other areas for more power first, then build the converter for the final combination. That means at least more compression and a lot bigger cam to go with it. I'll be able to do some more testing tomorrow and can go from there I guess. |

Posted By: tached_out

Date Posted: Dec/15/2017 at 9:18pm

|

Interested to hear how you did. I don't think anyone asked you what your end goal is.

|

Posted By: WesternRed

Date Posted: Dec/16/2017 at 5:00am

|

I can run 11.00 before I have to install a cage, so that is the goal, but not on this motor I guess. Unfortunately I didn't get to run today, was a car show at the strip with some racing on the side. They decided at the last minute that they didn't want any trailer queens running, only "street cars" that were driven there, which was a bit annoying after being advised otherwise previously. Anyway I did check a few things before heading down there. I made a better masking tape timing indicator and it looks like I have 15 degrees initial, plus 15 degrees mechanical, plus 8 degrees vacuum advance, so 38 degrees total. Would have been to test this and probably more initial without the vacuum advance to see what happens. I did verify TDC with a dial gauge rigged up down the spark plug hole and as far as I can tell, it's pretty much spot on. Also checked the plugs, which look pretty good to me:  Did a compression test: 1: 130 2: 130 3: 130 4: 130 5: 125 6: 120 7: 125 8: 130 Ok I guess for a stock 360 with 8.5:1 compression. I have a leak down test kit but couldn't get that to work, I think it's broken and really a 2 man job as far as I can see, so gave up at that point. Not sure what next other than seeing if it runs any better with more timing. |

Posted By: 70amcpwr

Date Posted: Dec/16/2017 at 5:30am

|

Compression is down a bit for what you want to accomplish, good that all them besides #6 are very close though. Past history for me has shown 5+6 to be the lower compression cylinders on an older motor. ------------- 70amcpwr You just can't fix stupid. SOLD 1970 BBO Javelin, wifes 73 AMX 360 4spd. Next project 1969 AMX |

Posted By: WesternRed

Date Posted: Dec/16/2017 at 6:10am

|

Ha ha, yes 11's would be the pipe dream when I build a 401 for it. I'm probably deluded, but I was hoping I could run low 13's with bolt on mods on this motor. I don't think there is enough compression there to run the 280H (needs 9:1), 270H perhaps? I did just lash out on a Holley Sniper setup since I can use the 600 Holley from the Gremlin on my Jeep, which doesn't have a carby at the moment. Not sure if there is much to be gained by running the Sniper and Torker on the current 360 though. |

Posted By: tached_out

Date Posted: Dec/16/2017 at 1:11pm

|

You still don't have enough spark advance. The 8 degrees vacuum you speak of, isn't there at wide open throttle. So you only have 30 when you need 38. You can ad that 8 degrees and quite a bit more to your 38.

|

Posted By: tached_out

Date Posted: Dec/16/2017 at 2:47pm

|

Free advice time. I’m sorry if this isn’t welcomed. Let me know and I’ll shut up. You have a drag strip only car. Disconnect the vacuum advance. Take it completely out of the equation. Vacuum advance is only needed when there is little to no load on the engine. let me explain; A stock passenger car engine has to perform adequately and offer the greatest fuel economy under a wide variety of operating conditions. From idle to cruising down the highway, the throttle is barely open. That means very little air and fuel can enter the cylinder during an intake event. The result, when that mixture is compressed, is you have relatively few air and fuel molecules in the combustion chamber and they’re relatively far apart. Under these conditions, the mixture is very slow to burn. The chain reaction (combustion flame front) is hindered by how far apart those molecules are. This is when you will typically need about 50 degrees of total spark advance at cruising rpm and about 40 degrees at idle. A good analogy might be to consider yourself trying to cross a stream. If the stepping stones are far apart you will have to jump from one then to the other. Once you land on a stone, you will need to build up enough energy to jump to the next one. All the while time is passing. Since time is of the essence here, you need to get started much earlier. Under wide open throttle conditions. The intake isn’t restricted. Well yours is somewhat but I’ll save that for another rant. Much more air and fuel will enter the cylinder on the intake stroke. When it’s compressed, there will be many more molecules in there and they’ll be very close together. The flame front as a result, will travel very fast. Using the stream analogy, you’ll have a paved path to run flat out across. It’ll take less time to cross, so you can start later. Here you only need about 38 degrees. Any additional vacuum advance won’t be available because there won’t be enough vacuum to make it work. This is good because it would destroy your engine if it was. Your race car only needs to start, idle around the pits and go go down the track at wide open throttle. You don’t need vacuum advance period. Here’s a tuning tip. With your current setup, with the engine idling, advance your distributor to 38 degrees. Watch how much your rpm increases and the exhaust gets quieter. It’s doing that because it’s producing more power by burning the fuel in the cylinder where it belongs and not the exhaust pipe. You will now close your butterfly more to get down to your desired rpm. This will give you a stronger vacuum reading and make the carburetor much more sensitive to the idle mixture screw adjustments. |

Posted By: WesternRed

Date Posted: Dec/16/2017 at 4:47pm

|

Your words are not lost on me tached-out, I just like to test things along the way to see what does and doesn't happen, it adds to the learning experience. The plan would have been to do a couple of runs with the current timing setup then drop the vacuum advance and add more initial to bring it back up to 38. After that I will need to find some advance springs to bring the advance on earlier. It would help if I had a dial-back timing light so that I can actually see what the advance curve looks like. As for the 600 Holley/Performer combination, I can see that being a limitation at the top end, but at the moment it is all done by 5,000 RPM, probably earlier. I can't really see that a Torker and bigger cby will help me get off the line any quicker, since that is where the problem is at the moment, happy to be proven wrong on this though. I think the big question is how far I can go with the cam on a stock low compression engine? I know the real answer is to open the motor and pump some compression into it, but then the dollars start to add up big time. Could try to find some cast 343 flat tops and a set of ARP rod bolts I guess for a real budget build, but once the motor comes apart, it never ends up that way. |

Posted By: WesternRed

Date Posted: Dec/17/2017 at 5:31am

| Is it just me, or do cast flat tops from Falcon Global cost nearly as much as forged flat top pistons from Wiseco? |

Posted By: scott

Date Posted: Dec/17/2017 at 6:51am

| Are you running a stock or aftermarket distributor?? |

Posted By: WesternRed

Date Posted: Dec/17/2017 at 6:57am

| Stock distributor with a Pertronix conversion. |

Posted By: WesternRed

Date Posted: Dec/17/2017 at 5:42pm

|

Here is a thought, I have a Comp XE262H, laying around, would need a freshen up, might be more suited to a low compression motor? I have the rest of the gear to go with it in terms of valve springs, retainers and locks, would just need to buy a new timing set. Another 80-100 HP would get me into the 13's theoretically. |

Posted By: 70amcpwr

Date Posted: Dec/17/2017 at 6:17pm

|

It sounds like you have a lot of stuff you could throw @ this motor, you just need to decided if you're going to keep trying to make it go faster w/o tearing it down or not. The most recent 390 I tore down the head gaskets (originals) were bad, I knew they were leaking anti freeze externally so I pulled the motor and put in a 390 I already had. When I pulled it apart they were leaking compression also as well as the intake was leaking. ------------- 70amcpwr You just can't fix stupid. SOLD 1970 BBO Javelin, wifes 73 AMX 360 4spd. Next project 1969 AMX |

Posted By: WesternRed

Date Posted: Dec/17/2017 at 7:21pm

|

Ha ha, yes I have a few things I could throw at it like another 360 I could build up or a couple of 401 blocks and cranks, but it all comes down to dollars at the end of the day. I just need this to run a semi-respectable time so that I can have some fun with it and move onto the next project. |

Posted By: WesternRed

Date Posted: Dec/20/2017 at 3:09pm

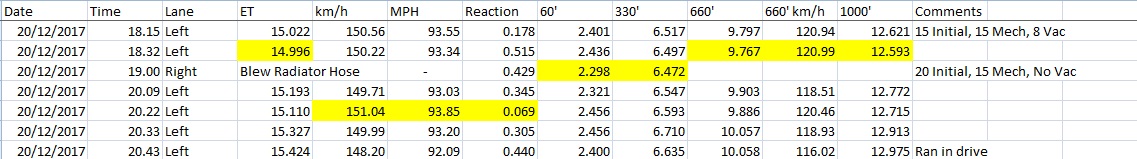

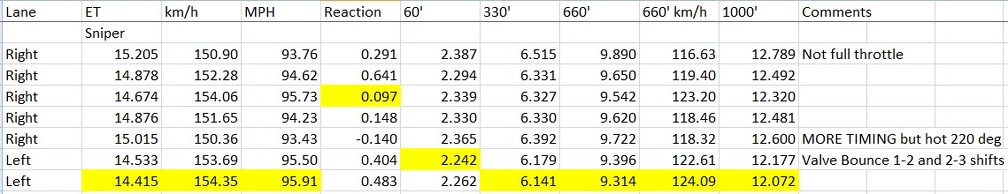

Amazing how much difference a bit of timing makes: First 2 runs were with 15 initial, 15 mechanical and 8 vacuum and the second run was the fastest of the night. Third run I disconnected the vacuum advance and advanced the initial to around 20 deg. Came off the line a little quicker but blew the top radiator hose off on the way down the track, which added a bit of excitement to the night. Probably would have been the best run of the night. Got back out on the track and the next run was also better in the 60' but slower ET. After that, the times went away a bit, we were pretty much hot lapping by then, so may have just got a little hot. Final run was done in Drive to see how it worked, 1-2 upshift is still coming in a little early. Good thing is the MPH is up around 93.5, so it's making more power, but 60' time still seems a little slow and there should be a bit more in it. |

Posted By: 70amcpwr

Date Posted: Dec/20/2017 at 5:59pm

|

Are you getting any wheel spin off of the line? If so for how many feet? What are you seeing for RPM @ the end? ------------- 70amcpwr You just can't fix stupid. SOLD 1970 BBO Javelin, wifes 73 AMX 360 4spd. Next project 1969 AMX |

Posted By: WesternRed

Date Posted: Dec/20/2017 at 6:50pm

| No wheel spin, I am running 10” slicks. Just on 5000 RPM across the line. |

Posted By: tached_out

Date Posted: Dec/20/2017 at 7:47pm

|

It's trying to tell you it likes timing. At the risk of sounding annoying, I'll tell you it still wants a bunch more. At 20 degrees initial, which is essentially what you're leaving the line with, it's still going to be a dog. The 10 degrees centrifugal isn't coming in until you're a couple of seconds into your run and quite a ways down the track. It's too little and too late. You got your best 60' with the most timing you've left the line with so far and it was still about 15 degrees too little. You need to start moving the car with around 38 degrees. With a less than optimal intake tract and being a little low on compression I bet it would like 40 degrees even more. Get this timing sorted out so you can leave it alone and start playing with the rest of the tune. |

Posted By: WesternRed

Date Posted: Dec/20/2017 at 8:29pm

|

Would probably help if I had a proper dial back timing light, at the moment I’m working with an old fixed timing light and masking tape on the balancer for the additional advance. Got a bit hectic last night after the big coolant leak, otherwise I could have experimented a bit more. At 20 initial it is getting a little harder to start, so messing with the advance springs is the next course of action I guess. I have ordered a Holley Sniper for it, so that will give me something else to play with, maybe I can use it to control the timing as well. |

Posted By: 70amcpwr

Date Posted: Dec/20/2017 at 9:18pm

Wouldn't a little wheel spin (RPM's ramping up) off of the line kick the centrifugal advance in instantly? ------------- 70amcpwr You just can't fix stupid. SOLD 1970 BBO Javelin, wifes 73 AMX 360 4spd. Next project 1969 AMX |

Posted By: WesternRed

Date Posted: Dec/21/2017 at 6:03pm

I'll just drop this here as well: Plan is to initially set it up on the performer with a 1" open spacer. I'm still thinking about a cam swap once it's up and running, so that would be a good opportunity to put the Torker on. Also saving the valve spring upgrade until after any cam swap so that I can break it in on the stock springs. |

Posted By: tached_out

Date Posted: Dec/21/2017 at 6:22pm

You don't need a dial back timing light. Here's all you do;

Measured the diameter of your torsional dampener. If you find it to be 6.7344 like mine is, all you need is a piece of tape 2 1/4'' long applied to the right of the line on the dampener. Or a line painted 2 1/4'' to the right. That is where 38 degrees before TDC is. Now just check that when all the centrifugal advance is in, your new mark at 2 1/4'' is in line with 0 or TDC on the timing tab. With super soft springs, that will happen at idle so there's no need to hang your face over all the stuff at the front of the motor spinning at high rpm. If you don't have soft springs, you can use those tiny elastic bands that people with braces on their teeth use. |

Posted By: WesternRed

Date Posted: Dec/21/2017 at 6:30pm

|

Masking tape on the damper has been working for me, but it tends to fall off, so maybe something a little more permanent would be the go (15mm = 10 deg). Dial back timing light that displays RPM as well would really help to be able to see when the actual advance curve. Handheld controller on the Sniper might do the trick as far as giving me a tacho I can see from the engine bay |

Posted By: S Curry

Date Posted: Dec/22/2017 at 11:44am

|

I have used timing tape available at just about any auto parts store. Just have to know the diameter of the balancer and peal off the correct sticker and stick it on. No need for a dial back light then. Worked for me setting up my timing and timing curve. ------------- SC |

Posted By: WesternRed

Date Posted: Jan/03/2018 at 4:58pm

|

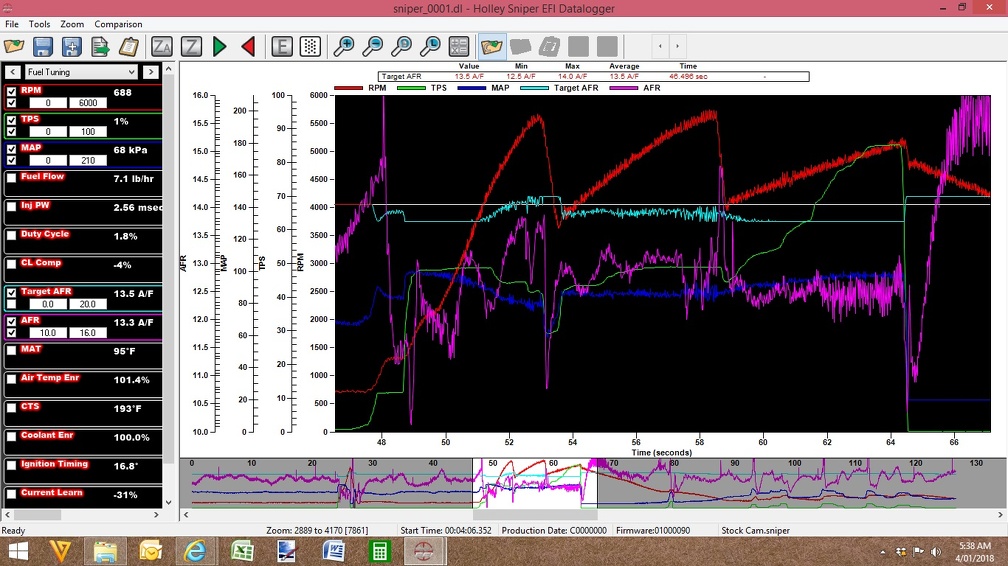

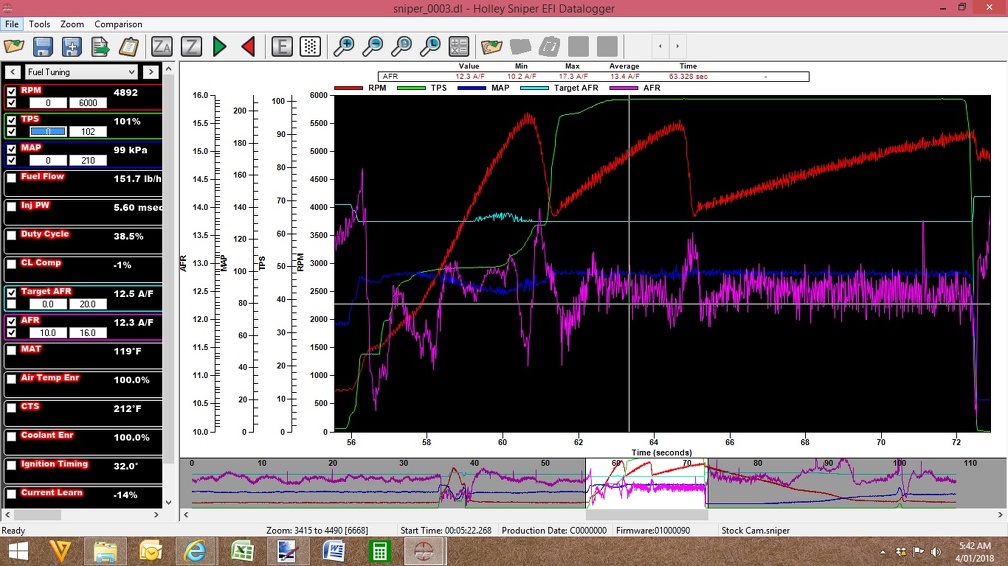

One of the great features of the Sniper is the data logging capability which records all of the system parameters for you and you can review these on a PC, pity you can't playback on the handheld though for more immediate use. You can hook the system up to a PC rather than the handheld though if you want a bit more capability in this area. Here is my first run from last night, 15.205 @ 93.76 mph, last I looked a stand alone data logger like this would cost nearly as much as the Sniper):  Pretty much on par for last time out, but what's very obvious from the chart (TPS line) is that I wasn't hitting full throttle. I pretty much figured this out without reviewing that data, but it is nice to see confirmation. By run 3, I'd got it down to 14.674 @ 95.72 mph with full throttle through 2nd and 3rd gears, not sure what's going on if first, maybe I just need to stand on the pedal a little harder:  Maybe someone more knowledgeable than me can give some insight into the data, seems like maybe it's going a little lean off the line. Full set of times and a new PB of 14.415 @ 95.9 mph on the last run:  Run 4, didn't get full throttle in 2nd and ran slower. Run 5, added some more timing since I've still got some work to do there. Did notice that the coolant temperature was pushing 220 after messing around with the timing, red lit as well as not on the throttle hard enough, so not a good run. Next two runs were much better, although I did push it a bit too hard on run 6 and had valve bounce at the gear changes. Somehow I managed to knock the SD card out of the handheld unit so wasn't able to log any data on the last 2 runs. Still lots to learn. |

Posted By: WesternRed

Date Posted: Jan/30/2018 at 4:07pm

|

Just re-checked the timing and it looks like I now have 20 degrees initial plus 18 degrees mechanical advance, all in by 1750 RPM, that was for the last three runs above. Back out tonight with the rear main seal and I have made some small changes to lighten up the throttle pedal so hopefully I can hit full throttle consistently. |

Posted By: WesternRed

Date Posted: Feb/01/2018 at 3:53pm

|

New PB first run off the trailer 14.245 @ 97.95, but couldn't match that for the rest of the night, next best was 14.307 @ 96.92. At least it's still headed in the right direction. Had issues shifting gears on a couple of runs going straight from 1st to 3rd, factory shifter is a bit touchy, not sure if there is a solution for that without going aftermarket? I will have a bit of a fiddle with the adjustment and see if that helps. Also struggles a bit with coolant temperatures, not many cars last night so the runs were coming around pretty quick. Seems the factory flex fan is not generating enough airflow so I think some electric thermo fans are a priority, might help a little with the times too. Best thing is now that I've changed the rear main seal, I don't need to wipe the bottom of the car down between runs.

|

Posted By: WesternRed

Date Posted: Feb/14/2018 at 11:33pm

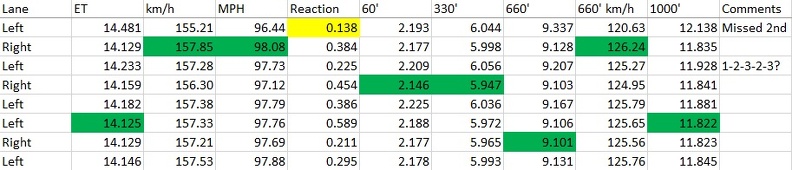

I've done an electric fan conversion since the last time out and can now maintain coolant temperatures around 185-195. It also helped a bit with the times, but maybe not as much as I had hoped, although I am thinking the previous PB of 14.245 may have been a bit of a freak run. The best thing about these times is that I'm starting to see some consistency (except for the crappy reaction times), but still having a few issues shifting as per runs 1 and 3. The question is what to do next, I do have a CRT reverse pattern manual valve body laying around. That might solve the gear selection issues if nothing else. It currently just has the stock valve body in it. Also still have the cam swap up my sleeve, but need to buy lifters and a timing set. |

Posted By: WesternRed

Date Posted: Feb/16/2018 at 5:53am

| PS: I know a 14 second car is pretty boring, but I need some help to make it go faster. |

Posted By: wantajav

Date Posted: Feb/16/2018 at 7:37pm

| 100 lbs off = 0.1 sec off.... |

Posted By: WesternRed

Date Posted: Feb/16/2018 at 9:53pm

| Onto that, already taken the bumpers off. Maybe the back seat could come out? |

Posted By: wantajav

Date Posted: Feb/17/2018 at 1:03pm

| is nitrous OK in Australia? Thinking a 75 or 100 shot at the most, might not be lethal to an old engine...that would get you near the 12's.... |

Posted By: WesternRed

Date Posted: Feb/17/2018 at 7:51pm

|

Nitrous is fine, but I don't have any plans of going there at this stage, looking more for incremental gains with what I have. The ultimate goal is to build a stout 401 for it but that is still a long way off and may never happen. Options I have at the moment are: 1) A cam swap, I have no idea what's in it at the moment, but I assume relatively stock. I also don't have a lot of compression, so can't go too crazy in this area. What I have is a reground Comp XE262H and matching valve springs, which should help things along a bit. Downside is I still need to buy lifters, and probably a new timing set, rocker studs, pushrods and cobble together some adjustable rockers (currently have a mixed set of 1.6 and 1.7 Harland Sharp). 1B) Valve springs came up earlier, currently it will valve bounce around 5500, not sure that I really need to rev it this hard at the moment. I have the better springs above, but if I'm going to change the cam then they can probably wait. 2) Change the transmission valve body, at the moment it is basically a stock rebuilt 727 with performance frictions and a bolt in sprag. I did buy a used CRT reverse pattern manual valve body a while back, so this can go straight in but I don't have the instructions and I am still trying to work out if it needs some other changes to the accumulator and servo valves to work properly. Not sure what gains to expect here. 3) Exhaust, headers and a better exhaust may help, but with a relatively low HP 360, I'm not sure what the headers would achieve over factory free flows. Dual 2" exhaust could be upgraded to at least 2 1/4" to match the free flows and probably some better flowing mufflers. 4) Timing is currently 20 initial + 18 mechanical all in by 1750 RPM (no vacuum advance), maybe still some gains here with additional tinkering? I'd like to do timing control with the Holley Sniper, but I need to change the distributor for that. 5) Tuning, the Holley Sniper seems to have dialed the AFR in around 12.2-12.7 at WOT, not sure if this is good or bad? Also going a little rich on launch (11.5) so maybe I can change that with some tinkering as well. Lots of research still required in this department to know what I'm doing. 6) Tyres, currently running 26" x 10" slicks, well and truly overkill at my power level, but at least I don't have any traction problems. I'm running them at 16 psi, it doesn't break traction, so no need to go lower, but maybe they are slowing down a relatively low powered car. Seems like a lot of options and probably others I haven't thought of yet. Would be good to have some other peoples experience with these things to use as a bit of a guide. So far every time I've taken it out. I've run a little quicker, so at least I'm going in the right direction.

|

Posted By: RUMBLR

Date Posted: Feb/19/2018 at 3:52pm

|

Id try a few more psi in the tyres - 25...then maybe keep going up? VPW have the amc lifters in their ebay store - 10% off at the moment... ------------- 343 904 M20 - 11.83@115 |

Posted By: WesternRed

Date Posted: Feb/19/2018 at 4:55pm

|

Can you run the slicks that high, certainly worth a try? Also considering if I should give the drag radials off the Javelin a try. Valve body change is looking like the most likely first candidate at the moment, just trying to track down the installation instructions and a few other bits by the looks of it.

Out of interest, Precision International carries Johnson Hylift and they were the ones recommended by the cam grinder over all others. They also have Rollmaster timing sets cheaper than from the US. |

Posted By: RUMBLR

Date Posted: Feb/20/2018 at 3:20am

|

Max pressure should be listed on the sidewall... there should be no issue and more stable at top end with more air.

------------- 343 904 M20 - 11.83@115 |

Posted By: WesternRed

Date Posted: Feb/20/2018 at 4:41am

| Sidewall only lists the maximum pressure when mounting the tires of 35 psi, no maximum operating pressure, tried looking on the MT website today and nothing listed there either. I'm sure a few more psi won't hurt. |

Posted By: Ken_Parkman

Date Posted: Feb/20/2018 at 3:14pm

|

If it is a race car only take the fan off and go to an electric. Also go to an electric water pump drive and take out the thermostat, deleting the heater hoses and bypass hose. That has multiple improvements, net hp increase and allows you to get the engine cool. Run the fan/water pump with the engine off and mist the rad with water from a cheap sprayer. Just mist, it sucks heat out like crazy as the water evaporates. Minimal effectiveness if there is still a thermostat in there. Get the temp below 140 on the starting line. The car will respond tremendously. Did you change to the torker? It and headers always help, even on a mild engine, especially with the right converter. The most important part of going fast is the torque converter. Quality is more important than stall speed. Max converter size of 10" for this. Those changes should get you into the low 12's without taking the engine apart. |

Posted By: WesternRed

Date Posted: Feb/20/2018 at 4:31pm

|

Thanks Ken. Just did the electric fan conversion, netted a couple of tenths there. Electric pump would be the next step. How much do you think the Torker will help over the performer with 1" open spacer on a low HP engine like this and max RPM of 5,500? Intake change may tie in with a cam change at some point. Headers would be nice, but are a fairly expensive proposition in Australia, wondering whether I will see much of an improvement with bigger pipes and better muffler on the free flows? Convertor upgrade is in a holding pattern, I spoke to the local convertor shop and they want around $1300 to build a convertor for it and politely suggested that I should spend my money elsewhere first and come back to see them a bit further down the track. One of the problems is that it is an early flat crank 360 with a custom made convertor to adapt the 727, so I can't look at off the shelf convertors either.

|

Posted By: Ken_Parkman

Date Posted: Feb/20/2018 at 7:21pm

|

Did not catch that you did the fan already, sorry. Get rid of the thermostat so you can run the fan and cool the rad without the engine running. Then start the engine and circulate the hot coolant, shut it off and cool the rad again. Repeat and get it as cool as you can and try that. One thing to think of is even with a 5500 shift point the engine only drops to 3300 on the shift to 2nd, 3800 to high. So the quoted low rpm advantages of a dual plane do not apply for performance use. With a stockish converter you do need some bottom end to launch the car. But with a 10", say 3500 stall, the engine is always in it's power band. Low rpm power is irrelevant. So I'm a performance guy, so the torker is the plan as for as I'm concerned. Low rpm torque is only for scaring the wife when you roll into it on the street. But remember this is a performance discussion, not street. But on a mild engine the difference is not going to be much, maybe 10 hp. With the cost of a custom converter I'd modify the crank. But unfortunately that means taking the engine apart. For sure if you do ever take it apart modify the crank for the standard TF converter. Don't take it to an automotive machine shop, go to a quality general machine shop with the PAS drawing. Then it's cheaper as long as the guy is reasonable. A good converter has the most performance effect. You can go fast with a good converter and a taxicab engine, but a race engine with a junk converter is a dog. I've been known to run a mild $800 spare parts 401 with a top notch 8" ATI, 5200 stall, on a 6000 rpm engine. That went 10.70's in the Hornet. Would not bother me at all doing that on your engine. But once again, we are not talking street use. The problem is you can't bolt it on, and I would not get a race converter from anyone other than a reputable RACE converter manufacturer.

|

Posted By: billd

Date Posted: Feb/20/2018 at 7:32pm

|

Holy cow, I guess my 2500 converter is a toy, then. LOL, oh, well........ Keeping my eyes on this as I have a 360 in my 73. The engine leaks oil, etc. so it may get freshened up some year so watching these results for budget tips. My next step is a different ignition system - it's still stock, in an almost 400 HP engine. -------------  http://theamcpages.com" rel="nofollow - http://theamcpages.com http://antique-engines.com" rel="nofollow - http://antique-engines.com |

Posted By: WesternRed

Date Posted: Feb/20/2018 at 7:54pm

|

Plenty to consider, I did pick up a spare late 360 crank to use down the track if I decide to freshen the motor and that would resolve any convertor compatibility issues. Torker is sitting on the shelf, so that could certainly go on. If I put the XE262H in with some new valve springs, that might give me a bit more RPM capability too. |

Posted By: PacerLarry

Date Posted: Feb/21/2018 at 12:13pm

|

My car is set up pretty close to what you have. I have a 904 not a 727, but when I changed over to a manual valve body, I picked up between 3 and 4 tenths with no other mods. I only shift at 5500 because the car falls off above, but with the factory valve body, I would always get a flare up on the 2-3 shift. A local guy that runs stock eliminator told me switching to radial slicks (different than drag radials) was good for a tenth on his car. Another trick to get your ET down is using the tallest front tires you can fit and staging as shallow as possible.

|

Posted By: Ken_Parkman

Date Posted: Feb/21/2018 at 3:45pm

|

Another advantage of a good converter is you don't have to rev the engine so high. The problem with a low stall, say 3500, is the engine drops all the way to the transmission input speed on the shift. So you drop way out of the max power range, so you have to badly over rev the engine to make the car quicker. With an 8" converter then engine does not drop on the shift so it stays at max power, the converter has a delta rpm so it goes back into torque multiplication, and you get way more power to the rear wheels. The trick is to keep the engine in it's power band, not above or below, for the entire pass. That's why a car with a race converter goes faster with a lower shift point. Go faster and easier on the equipment - what's not to like? So obviously I vote for the good converter. But I have to stress the importance of the word "good". I've had a junk converter eat 100 hp. It had the stall, but not the design. And since most people (me at the time) don't understand how important it is they only look at stall speed. If someone has been in there bending fins to mess up the converter efficiency and get an artificially high stall it's a piece of junk. I spent a whole summer trying to find my missing power in the engine, when all along the engine was fine and the converter was junk. So go to a reputable RACE converter manufacturer. And if the diameter if wrong for the application run away. |

Posted By: WesternRed

Date Posted: Feb/21/2018 at 6:53pm

Thanks, that the sort of info I was chasing regarding the valve body change, if I can pick up 2 tenths with that, I'm in the 13's. Valve body is sitting here gathering dust so it might as well be in the transmission, bought it off a mate who upgraded to a trans brake. Ken Parkman, you are preaching to the converted.  The things holding me back on a convertor change are the cost for a good one (that's a biggie), the stupid flat crank in my motor and the thought that if I get something that is optimised for what I have now, then it probably won't be optimal if I make other upgrades down the track and I might have to spend the money twice. Might be something to think about more over the winter break (it's summer here at the moment). PS: The current convertor stalls at around 1400. |

Posted By: AMC instigator

Date Posted: Feb/22/2018 at 12:49am

|

Sounds like you have been slowly working in the right direction. I have seen some great suggestions, from some very good racers. I'll just add a few. You might try airing up the slicks to 20 and run it, then add a psi each time time it wont hook any longer. 10 inch slick is wider than you need so it creates scrub. The Torker is better. A 1" 4 hole spacer will give it better throttle response with your stock convertor. Do not "stall" up the convertor, leave off a dead idle, and hammer the throttle, it will stall a bit more, bringing the 60 down. The timing works fine on a low compression stocker at 20 initial. I have a couple at 22,and a total at 42, and run them that way. If you get a chance for a distributor tuning kit, set the initial with the old tight springs at 20, then install and use use one lightest spring, and one med. This will bring it in right on for your 360 and 4:10. You must set the initial with tight springs, the weak ones will bounce. Or you can set it at 3000 using your total of 40. Vacuum advance is no longer hooked up or used. So you are aware the manifolds are holding back 3 tenths. No problem, but I figured you would like to know cheap headers would gain that without issue. The 262 cam you have is too small. It would be best to leave what you have, or put in a 270H Comp, providing your leaving the convertor. If however you install the convertor Ken P suggested install a 280H Comp. Don't worry about the compression and the cams, it will make you smile. The tips you have gotten on this thread from many good racers will make the car turn 13's without much more than a few adjustments, and low 13's with a cam and header install, the good convertor as well, that's 12's. That is with 8.5 compression. Hope that helps SH ------------- AMC RACES event coordinator Former NAMDRA Vice President- NAMDRA-#2398 AMO-#8370 Northstar AMC Club-#9 |

Posted By: wantajav

Date Posted: Feb/22/2018 at 1:03pm

|

Has this been suggested? Going to the smallest lightest rear tire /rim combination you can run without excessive spinning to get a quicker shot off the line. Maybe you don't need a 10" slick with this car. Thinking a smaller rear tire would also be like running a slightly higher (numerically) rear gear ratio. Less wheel/tire inertia to overcome as well. Great reading , really enjoying this thread!

|

Posted By: WesternRed

Date Posted: Feb/22/2018 at 4:29pm

|

The 26" slicks on there at the moment are pretty small diameter in the scheme of things unless I want to drop down to a 14" wheel. Being 10" wide is definitely overkill though, but they were cheap and look cool. Will definitely look at other options when they wear out. Probably better served by running drag radials, but the slicks are actually quite lite in comparison. I also have to be a bit mindful of terminal speed since I can't rev it to 6,000 or 7,000 RPM. Interesting thoughts on the cam SH, I was originally thinking 280H, but was talked out of it due to the lack of compression. The XE262H is pretty close to the 270H, slightly smaller on the intake and slightly bigger on the exhaust. The really good thing about last time I ran it, was that I was getting pretty consistent times, so I will have more confidence in making small changes at the track. Previously the times were so inconsistent that it would be hard to tell if something like a small timing change made any difference. One of the aims with this car was to get a lot more seat time so that the driver can get tuned up as well.

|

WesternRed wrote:

WesternRed wrote: