Low vacuum and miss-304

Printed From: TheAMCForum.com

Category: The Garage

Forum Name: AMC V8 Engine Repair and Modifications

Forum Description: AMC-made V8 engine mechanical, ignition and fuel from basic repair to high-perf modifications

URL: https://theamcforum.com/forum/forum_posts.asp?TID=61961

Printed Date: Apr/23/2024 at 8:25am

Software Version: Web Wiz Forums 12.03 - http://www.webwizforums.com

Topic: Low vacuum and miss-304

Posted By: ollie09

Subject: Low vacuum and miss-304

Date Posted: Jul/13/2014 at 7:24am

|

Just got my rebuilt 304 installed in a 77 Jeep. It started right up and idles fine. But at anything over 1200 RPM's, it has a miss. Also, in order for it to run, the timing is way off the mark on the dampener. Manifold vacuum is only 12" at idle and goes to 18-20" over 1200 RPM. Vacuum advance not connected. Couldn't find any vacuum leaks. Both the dizzy and carb are new reman units. >Pulled all the plugs and checked compression. All are 145-155 PSI. This engine only has 20 minutes run time. >Pulled the left rocker cover and confirmed TDC when both rockers are closed and verified piston was at TDC by watching the top of the piston through the spark plug hole. >With crank in this position, timing mark on dampener was right where it should be and rotor pointed to #1 on the cap. The guys on the Jeep Forum thought I had the timing chain one tooth off so I pulled the front cover off and confirmed that there were 20 pins between timing marks, just as there should be. What else could it be? |

Replies:

Posted By: Boris Badanov

Date Posted: Jul/13/2014 at 8:43am

|

Stock re-build? If not 100% stock you need to list what you have done. But, right out of the gate be sure the condensor is good, replace it if you got a spare, and be sure the distributor and condensor ground is perfect. ------------- Gremlin Dreams |

Posted By: purple72Gremlin

Date Posted: Jul/13/2014 at 8:50am

| Reman distributor and carburetor? I sure would look at them.. |

Posted By: 304-dude

Date Posted: Jul/13/2014 at 9:39am

|

sounds like the cam gear was not intalled right, it can be installed in reverse, and the oiling channel could have been used to align the gears. believe it or not the engine can run, just will not have power. ------------- 71 Javelin SST body 390 69 crank, 70 block & heads NASCAR SB2 rods & pistons 78 Jeep TH400 w/ 2.76 Low 50/50 Ford-AMC Suspension 79 F150 rear & 8.8 axles Ford Racing 3.25 gears & 9" /w Detroit locker |

Posted By: ollie09

Date Posted: Jul/13/2014 at 10:12am

|

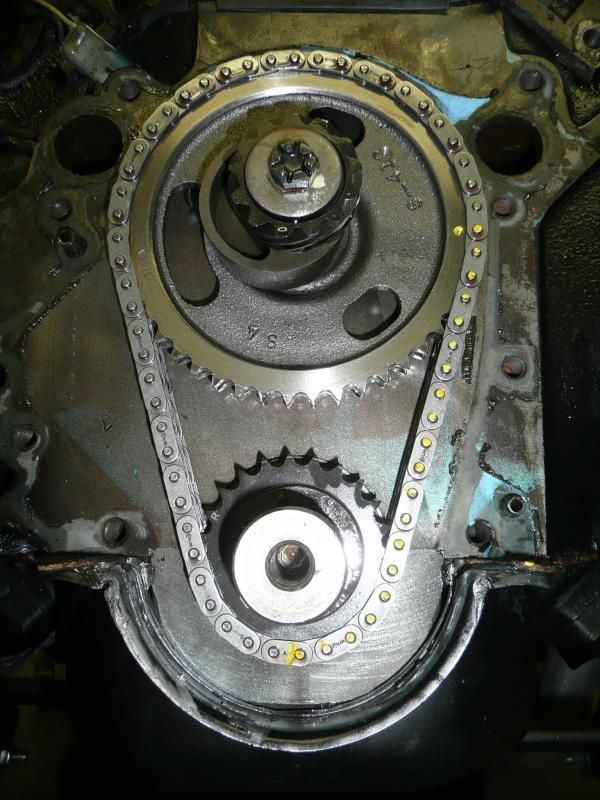

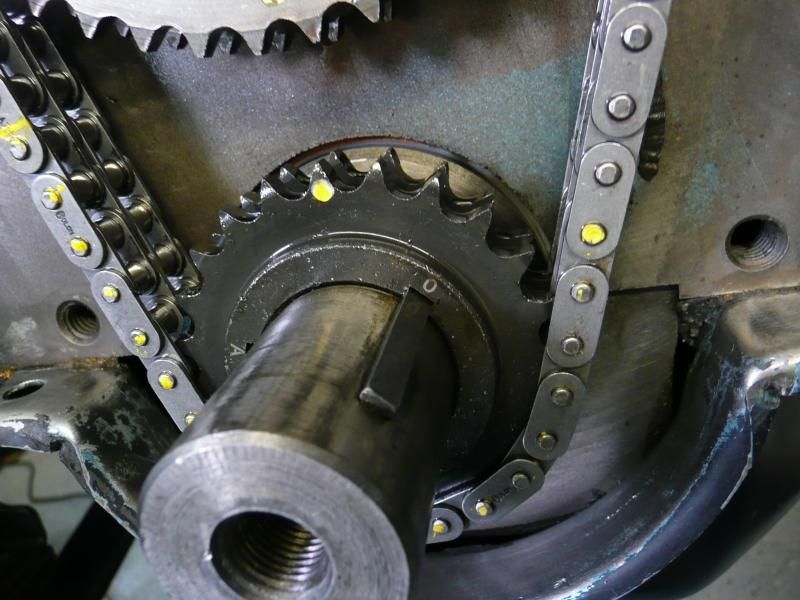

It is a stock rebuild except for a mild Comp XE262 cam. New lifters, rocker and push rods. The engine ran the same way with the original carb and dizzy. It idles fine and starts right up. I set the timing with a vacuum gauge since the timing mark didn't show on the dampener. Also checked the new (rebuilt) dampener to another one and the key way lines up correctly with the timing ma5rk. http://s63.photobucket.com/user/duke94_photos/media/timingchain-1.jpg. -  This photo shows the crankshaft gear with the "o" lining up with the keyway. http://s63.photobucket.com/user/duke94_photos/media/Timinggear2.jpg. -

|

Posted By: ollie09

Date Posted: Jul/13/2014 at 10:14am

Would an ignition problem result in low vacuum? |

Posted By: RAZER

Date Posted: Jul/13/2014 at 10:18am

| What brand spark plugs are in it? |

Posted By: rockAMX

Date Posted: Jul/13/2014 at 10:38am

|

Weights on distributor stuck? Could be seized up. Easy to check. ------------- DWR 1968 AMX  |

Posted By: Boris Badanov

Date Posted: Jul/13/2014 at 11:43am

Yes. Low idle vacuum can be the result of bad initial timing and bad condensor. At higher engine speeds the combination of mech advance weights and the vacuum advance will bring the advance up along with the manifold vacuum. "hot" cam timing will have the same result. I sense the whole problem here is in the ignition system or vacuum plumbing.

------------- Gremlin Dreams |

Posted By: ollie09

Date Posted: Jul/13/2014 at 11:44am

Checked the weights and everything moves freely. |

Posted By: Boris Badanov

Date Posted: Jul/13/2014 at 11:48am

|

I looked up that camshaft, it's fairly hot for a stock 304, but not too much at all. try a condensor and try running the motor with no vacuum advance hooked up. I would expect higher vaccum at 2000 rpm + than idle with any cam, but even more so with that one. ------------- Gremlin Dreams |

Posted By: ollie09

Date Posted: Jul/13/2014 at 11:50am

|

Would an ignition problem result in low vacuum? [/QUOTE] Yes. Low idle vacuum can be the result of bad initial timing and bad condensor. At higher engine speeds the combination of mech advance weights and the vacuum advance will bring the advance up along with the manifold vacuum. "hot" cam timing will have the same result. I sense the whole problem here is in the ignition system or vacuum plumbing. [/QUOTE] There is no condenser, it has the stock electronic ignition. I set the timing for the highest vacuum I could get, 12". It has a 'new' after market ignition module. Unfortunately, I didn't try the old one before I pulled the front cover off. I figured if it runs it must be good. |

Posted By: Boris Badanov

Date Posted: Jul/13/2014 at 11:51am

This from a website running a 9.25:1 SBC 350 with that same cam grind

------------- Gremlin Dreams |

||||

Posted By: Boris Badanov

Date Posted: Jul/13/2014 at 11:59am

Yes. Low idle vacuum can be the result of bad initial timing and bad condensor. At higher engine speeds the combination of mech advance weights and the vacuum advance will bring the advance up along with the manifold vacuum. "hot" cam timing will have the same result. I sense the whole problem here is in the ignition system or vacuum plumbing. [/QUOTE] There is no condenser, it has the stock electronic ignition. I set the timing for the highest vacuum I could get, 12". It has a 'new' after market ignition module. Unfortunately, I didn't try the old one before I pulled the front cover off. I figured if it runs it must be good. [/QUOTE] You are in a tough spot. I now think you need a drastic distributer re-curve. That cam and compression combo needs about 16-18 degrees initial but the distrubiter may have up to 38 degrees in the mechanical advance alone. I think this a job for a guy that knows that distributer better than I. But I will open the circus with this comment. For a test only. I would try to lock out all advance in the distrubuter and set it for 32 degrees initial. No mech advance, no vaccum. Run it. Work from there, maybe 15 degrees mech advance in the dist, no vacuum advance till you get the curve correct. In my old AMC rigs I used to run 15-25 degrees initial depending on cam and compression. Never more than 36 total not counting the vacuum advance. Stock was around "0" degrees initial. ------------- Gremlin Dreams |

Posted By: ollie09

Date Posted: Jul/13/2014 at 12:19pm

Plugs are Champion 3405 set at .035". |

Posted By: Boris Badanov

Date Posted: Jul/13/2014 at 12:21pm

|

Plugs are fine, I now think it's excessive total advance after setting the engine for max idle vacuum. ------------- Gremlin Dreams |

Posted By: ollie09

Date Posted: Jul/13/2014 at 12:29pm

|

This is my first AMC V8 rebuild. Done many SBC over the years so this has been a new experience for me. On SBC, we never bothered with initial timing but rather set max timing using a dial type timing light to get 38 degrees total advance at 3500 RPM. Before I put it back together to try some of the other suggestions, does everyone agree that the cam looks to be installed correctly? I appreciate everyone's input since I'm new to AMC's. I have a 360 to build after this one, so I hope to learn from my mistakes. |

Posted By: rockAMX

Date Posted: Jul/13/2014 at 1:25pm

|

A stock 304 is around 5 degrees advanced at curb idle. Since you have the stock distributor, this should be about right. Adding the cam won't change that but upgrading to a higher performance distributor will. I would just start with 5-7 degrees at curb idle and rev her up. Make small changes in timing from there. You will get it. Some recommend getting the engine warm to curb idle then advance the distributor to achieve the highest idle, then retard it just a touch, then drive it and test.

------------- DWR 1968 AMX  |

Posted By: ollie09

Date Posted: Jul/13/2014 at 1:27pm

| Not sure if I mentioned this, but if I slow the idle way down (500 RPM), the timing mark comes into view. This would seem to be the advance weight springs, but I've had 2 different Dizzy's in it and both do the same thing. I see one heavy spring and one light spring, does it matter which goes where? |

Posted By: FuzzFace2

Date Posted: Jul/13/2014 at 1:28pm

|

To me a motor is a motor and other than where #1 might be, how they number the cly per bank and firing order what works for one should work for them all.

At first I thought you did not have enought timing to start with but yo usaid you set it with a vac. gauge to the highest then I dont know what it could be?

The other thing that got me is yo usaid you could not use a timing light because the mark did not show up?? You did check the old & new dampers and they were the same so now why no timing mark with the light and no vac or RPM?

Did I also read you had this same thing before the rebuild?? If so what are you using that is the same from the old motor to new motor? Being others think timing and the dist might be new or was new to the old motor trying to fix this issue it might not be the dist but what about the IGN box?

Dave ---- ------------- TSM = Technical Service Manual 75 Gremlin X v8 for sale 70 Javelin 360/auto drag car 70 Javelin 360/T5 Street car |

Posted By: Boris Badanov

Date Posted: Jul/13/2014 at 1:38pm

|

Your cam timing is correct. Like a SBC, 36-38 total is good. Replace the advance springs with safety wire to lock out the mech advance then set it for about 16 degrees, try it. There is little risk other than breaking a starter by setting it to 36 deg right out of the gate. On my old gremlins and Javlins and a 390 Ford I set them at 36~ and used a seperate ignition switch to light it off after the starter was turning. We also used that on every Drag car I was involved with.

------------- Gremlin Dreams |

Posted By: ollie09

Date Posted: Jul/13/2014 at 3:12pm

| OK, I'm going to put the front end back together so we can continue trying to find the root cause. Will report back when I get it running again. |

Posted By: FSJunkie

Date Posted: Jul/14/2014 at 12:03pm

------------- 1955 Packard 1966 Marlin 1972 Wagoneer 1973 Ambassador 1977 Hornet 1982 Concord D/L 1984 Eagle Limited |

Posted By: budryzer

Date Posted: Jul/14/2014 at 4:29pm

|

Greetings, I was looking at the first picture and noticed a mark on the block. It's just outside of the cam gear chain at about the 1 O'clock position. Is this a crack? Also, which intake manifold are you running? Intake gaskets? Valley pan? ------------- 1968AMX Stroked 369 "UNCLE SAM" tribute 04 H2 04 BMW 325 A/W 95 Ultralight Hobbycopter 85 CR500 x 2 and 13 other open Class Bikes 77 Hercules Chinook Flt Lead Prev 1970AMX390/4spSonicw/mask&3Gremm's |

Posted By: hornet304go

Date Posted: Jul/14/2014 at 6:13pm

| The timing chain marks can be lined up . But if you put the dist in one tooth off, the timing mark will be off the scale to make it run. The dist rotor has to be pointing to the number one position on the cap, when the intake and exhaust valves are closed. Since it's not back firing out the carb, your not off 180 degrees. |

Posted By: ollie09

Date Posted: Jul/14/2014 at 6:33pm

|

Hi, I just went out and looked at it. Must have been some left over RTV as I've cleaned up the block to get ready to reassemble the cover and it is gone. The intake manifold is the stock cast iron 2 barrel job with the stock metal gasket/valley pan. |

Posted By: ollie09

Date Posted: Jul/14/2014 at 6:35pm

|

Hornet304, I confirmed that when the crank pulley is at TDC, the rotor is pointing to the #1 plug. |

Posted By: budryzer

Date Posted: Jul/14/2014 at 6:43pm

|

It could be a lean miss.... If the vacuum is low, under 14 or so, then it's pulling in air elsewhere. There are a few different was of finding leaks. The most exciting one I have heard of is using a propane torch. Letting it dump the gas while running the engine and wait for the increase. It could be some thing as simple as a carb issue, cracked base plate, etc. Since it happened before the rebuild and exists now, find the common items and look there. You'll get it eventually, be persistent. Sometimes a second set of eyes can help find the trouble area. ------------- 1968AMX Stroked 369 "UNCLE SAM" tribute 04 H2 04 BMW 325 A/W 95 Ultralight Hobbycopter 85 CR500 x 2 and 13 other open Class Bikes 77 Hercules Chinook Flt Lead Prev 1970AMX390/4spSonicw/mask&3Gremm's |

Posted By: ollie09

Date Posted: Jul/14/2014 at 6:50pm

I like the lean miss idea. Have you tried the torch method? I assume you need a special probe of some sort, not just an unlit propane torch. Gotta get this thing back together so I can continue the hunt. |

Posted By: greasygt III

Date Posted: Jul/14/2014 at 7:18pm

|

I sort of looked at all the posts and I have seen this before. Whether or not it is your problem, I don't know. Assuming you have power breaks, have you removed and plugged the vacuum at the intake? Try it. A bad booster can get you looking in all the wrong places. ------------- 83 Spirit GT 79 Ranchero GT 460 |

Posted By: ollie09

Date Posted: Jul/14/2014 at 7:28pm

|

It has manual brakes. One thing I just thought of, there is a plate on the bottom of the intake manifold. No gasket came with the gasket kit so I made one out of high temp gasket material. How would I ever be able to tell if this leaks? |

Posted By: greasygt III

Date Posted: Jul/14/2014 at 7:38pm

|

Are you talking about where the intake contacts the heads? If that is what you meant you could try the propane trick (I've never used it) but what I do use is carb cleaner. Spray around the matting surfaces while the engine is running and see if there is an increase in RPM without touching the throttle. You can even do this with other areas to check for vacuum leaks. STAY AWAY FROM HOT EXHAUST MANIFOLDS. ------------- 83 Spirit GT 79 Ranchero GT 460 |

Posted By: FuzzFace2

Date Posted: Jul/14/2014 at 7:59pm

I am thinking it might be the PCV baffle plate and did not need a gasket.

That brings me to the PC Valve. Do you have one installed and if so remove it and plug the hose and see if the vac readings go up.

Dave ---- ------------- TSM = Technical Service Manual 75 Gremlin X v8 for sale 70 Javelin 360/auto drag car 70 Javelin 360/T5 Street car |

Posted By: ollie09

Date Posted: Jul/15/2014 at 5:50pm

Here's the plate I referred to. It is under the sheet metal splash pan. The hole it covers goes right through to the other side http://s63.photobucket.com/user/duke94_photos/media/Intakemanifold.jpg. -

|

Posted By: rockAMX

Date Posted: Jul/15/2014 at 6:35pm

|

Is that hole for the EGR? Post-72 intakes had an EGR valve. Why would it have a plate? Maybe so it could be used without the EGR. That won't affect engine vacuum so a gasket is not necessary.

------------- DWR 1968 AMX  |

Posted By: dbomb

Date Posted: Jul/15/2014 at 6:59pm

|

Egr cleanout, It could have a stuck or bad egr valve or a stuck heat riser or clogged exhaust . That can push open the EGR and drop vac down low and bog badly. Had a jeep that had a bag egr and when the wind blew in the tailpipe the air would make downdraft through intake and pull fuel from carb bowl til it was dry we thought it had a bad check valve in the gas filter(stock AMC gas filters do) but when guy parked car in garage with no wind he didnt have problem . Some years of the 2V carbs have a mixture device on back of carb that gets warped and leaks vacuum internally and runs way lean wed resurface on a belt sander at machine shop. ------------- rebuiling 73 amx need parts |

Posted By: dbomb

Date Posted: Jul/15/2014 at 7:05pm

|

The vacuum problem is really strange you should have max vacuum at idle not when throttle cracked . Did you mill the heads a whole lot or something maybe the pushrods too long from heads being milled Im sure you probably have stock pedestal rockers correct? can you spin pushrods when valve closed.Maybe Im reading too far into this Is it running on all 8 cyls.. ------------- rebuiling 73 amx need parts |

Posted By: budryzer

Date Posted: Jul/15/2014 at 8:39pm

|

Hmmnnn I personally have not seen that access. I have had two 304's but am not familiar with that. Does that allow access into the plenum? It appears directly under the carb..? If so, get an aftermarket and throw a nice four barrel on it and you should be GTG. ------------- 1968AMX Stroked 369 "UNCLE SAM" tribute 04 H2 04 BMW 325 A/W 95 Ultralight Hobbycopter 85 CR500 x 2 and 13 other open Class Bikes 77 Hercules Chinook Flt Lead Prev 1970AMX390/4spSonicw/mask&3Gremm's |

Posted By: ollie09

Date Posted: Jul/15/2014 at 8:58pm

No, the EGR is at the back on the other side of the manifold. This is the manifold for the 360 I'm going to build next, but the one on the 304 is the same. I have no EGR valve, it has a blockoff plate. |

Posted By: ollie09

Date Posted: Jul/15/2014 at 9:01pm

Yes, it goes right into the plenum below the carb. It is machined like something would bolt on to it as opposed to a pipe plug like what's in the back end of the manifold. I have 2 stock manifolds and they are identical. |

Posted By: ollie09

Date Posted: Jul/15/2014 at 9:08pm

The heads were just kissed off to get them flat. My machine guy says .003-.004" max. Yes, the rockers are the stock pieces. I have not checked to see if the push rods turn. On a SBC, you turned the adjusting nut until you can't turn the pushrod, then give it 1/4-1/2 turn more. You could not turn the pushrods after this adjustment. There is no adjustment on this engine so however the parts stackup is the way it is. Is there something else I should do with the valve train? Yes, it seems to be running on all 8 at idle, but has a miss at 1200 RPM and above. |

Posted By: budryzer

Date Posted: Jul/16/2014 at 6:56am

|

Yeah, I would look into just going with a used 4 barrel manifold and rebuild yourself a nice holley and see how that works. Being that both of your manifolds have the same access, it must be stock...... Cali smog or something? Someone else should chime in. You might need to repost just the manifold and state an "identify this manifold" type subject? I still have one 304 (1970) that i'm waiting to find a good vega or pinto to drop it in and go racing:) ------------- 1968AMX Stroked 369 "UNCLE SAM" tribute 04 H2 04 BMW 325 A/W 95 Ultralight Hobbycopter 85 CR500 x 2 and 13 other open Class Bikes 77 Hercules Chinook Flt Lead Prev 1970AMX390/4spSonicw/mask&3Gremm's |

Posted By: ollie09

Date Posted: Jul/16/2014 at 9:22am

|

I'll do that. There are 2 holes drilled from the bottom side to the top connecting the left and right sides of the manifold. I believe both engines are from the West coast so maybe it is a smog thing. http://s63.photobucket.com/user/duke94_photos/media/Intaketopview.jpg. -

|

Posted By: rockAMX

Date Posted: Jul/16/2014 at 11:14am

Right into the plenum? Get rid of that manifold. Edelbrock performer without EGR is what I have on my 304. ------------- DWR 1968 AMX  |

Posted By: rockAMX

Date Posted: Jul/16/2014 at 11:36am

|

What could possibly bolt on to this? Would have to be bolted on from the underside of the intake. Imagine if fuel vapor leaks down past the plate at low vacuum. Boom. ------------- DWR 1968 AMX  |

Posted By: Boris Badanov

Date Posted: Jul/16/2014 at 11:43am

|

I would tap it for a pipe plug then lock tight it in.

Or better yet junk that manifold and throw an

air gap or performer on it.

I have a 1975 401 iron intake here and that "feature"

is not on it. ------------- Gremlin Dreams |

Posted By: Boris Badanov

Date Posted: Jul/16/2014 at 11:47am

|

If that motor is sucking un metered exhaust gasses in through those two holes

then you have found your problem! ------------- Gremlin Dreams |

Posted By: tsanchez

Date Posted: Jul/16/2014 at 11:57am

|

Those holes are where the exhaust is recirculated into the intake charge, both holes meet under the intake and if you notice the underside there is two passages going toward egr location, one is for those holes and other is to exhaust port crossover. That cover needs to be sealed up or there will be a vac leak, also if the plate that is blocking the egr is not sealing each port and leaks it will bleed ex into intake charge.

------------- http://s192.photobucket.com/user/antonsan/media/jav1_zps87a70dce.jpg.html" rel="nofollow">

|

Posted By: ollie09

Date Posted: Jul/16/2014 at 12:03pm

Thanks for the info. I better look close at my EGR block off plate and the plate on the bottom of the manifold. It sounds like I don't want this intake anyway since it seems to be a smog type. |

Posted By: ollie09

Date Posted: Jul/16/2014 at 3:06pm

| Has anyone actually tried to put the front cover back on without dropping the oil pan? I've had 2 failed attempts. Can't get it lined up without having the short pieces of pan gasket that come with the cover kit move out of place. Removed the lower pin per the instruction. Gotta walk away from this thing for a while. |

Posted By: Boris Badanov

Date Posted: Jul/16/2014 at 3:21pm

|

Not here.

I have got away with just loostening the pan, but I

had to lower it about .125" at the front.

------------- Gremlin Dreams |

Posted By: budryzer

Date Posted: Jul/16/2014 at 5:01pm

|

Only once and a very long time ago. I do remember loosening most of the pan bolts, maybe even all of them? to get the front down enough to seal it back up. Good news is I think you've got your issue narrowed down? :) ------------- 1968AMX Stroked 369 "UNCLE SAM" tribute 04 H2 04 BMW 325 A/W 95 Ultralight Hobbycopter 85 CR500 x 2 and 13 other open Class Bikes 77 Hercules Chinook Flt Lead Prev 1970AMX390/4spSonicw/mask&3Gremm's |

Posted By: ollie09

Date Posted: Jul/16/2014 at 6:51pm

| Now I have to wait for new gaskets. I think I will lower the oil pan so I can get a better seal with the bottom of the cover. Trying to do it the way they suggest in the Fel-Pro kit just makes a mess. I did machine up an alignment pin to use at the lower locate pin until all the bolts are started. |

Posted By: dbomb

Date Posted: Jul/16/2014 at 10:03pm

|

I used to have to do this quite a bit at the Jeep dealer I worked at to hold gasket we used crazy glue. Or later we got better RTV sealant from the Chevy dealership down the street and just sealed it with no gasket. They had some really good Gray and white colored sensor safe sealers that were wonderful 15 buck a tube but they were worth it..Chevy didnt even sell oil pan gaskets on alot of their motors back then . We also used that to glue on the plastic 258 Valve covers when they leaked even on the update kits. ------------- rebuiling 73 amx need parts |

Posted By: dbomb

Date Posted: Jul/16/2014 at 10:21pm

|

Looks like an EGR manifold and you nprobably have the carb with the altitude compensator on the back which warps and hiccups. or a blown powervalve. The Chevy rochester 2 barrels are bulletproof and foolproof No pwervalve no funky stuff only problem they have is baseplate screws coming loose sometimes and they come in 2 sizes .We put of these on 6 pin Jeeps with the fuel feedback carter carb and they were really good .The bolt pattern different but theres adaptors out there. Small 2v is on the 307 type motors the bigger 2v on 350s and 400s in Impalas vans pickups and stuff > Chepest way out is get Boris Manifold and get a small rochester Nonn fuel feedback non computerized spreadbore and youll have good power and fuel economy. Check your actual dwell with a meter as gapping points is ok as a start but when the advance comes in it can change if the breaker plate gets cocked or if the distributor shaft bushings are bad. Dwell is the way you measure the amount of time points are open. If youre not familiar the chiltons manuals tell ya about it. I was looking at a Jeep Cherokee Chiltons today and it said that Low Vacuum at Idle and rises as throttle open could be clogged exhaust or heat riser It makes sense if the EGR is opening it will drop vacuum, sorry to go on and on. ------------- rebuiling 73 amx need parts |

Posted By: ollie09

Date Posted: Jul/18/2014 at 7:53pm

What do think of just using RTV for the 2 little pieces of cork gasket at the front of the pan? That would make the whole job a lot easier and I wouldn't have to lower the pan. |

Posted By: dbomb

Date Posted: Jul/19/2014 at 12:30pm

|

yup thats what we did gotta be clean and use good brand rtv let it setup a few minutes before ya tightn the bolts . If the rubber crescent gasket keeps falling down glue it to timing cover with a little spray adhesive or crazy glue . ------------- rebuiling 73 amx need parts |

Posted By: ollie09

Date Posted: Jul/27/2014 at 4:48pm

|

Update. Well, I finally got it all back together today and started it up. Barely started and wouldn't stay running. It seemed like it was running on 4 cylinders, and I still couldn't get it timed. I replaced the EGR blockoff plate with an EGR valve to eliminate the plate as a cause. I also checked the gasket on the bottom of the manifold by spraying WD-40 on top the gasket and waited to see if it leaked out, it didn't. As a last resort, I replaced the new aftermarket ignition module with the original one. It fired right up and ran on all 8! Was even able to see the timing mark and set the dizzy correctly. Still has only 12" vacuum at idle, but I'm thinking the cam I used (COMP XE262) is more aggressive than I thought. It seems to run well in the garage with NO MISS. Still have to give it a go on the road. Next weekends project. I appreciate all the support you guys gave me in trying to diagnose the problem. It helps to have a dialog with others as 2+ heads are better than one old one.

|

Boris Badanov wrote:

Boris Badanov wrote: