Borg Warner M12 for performance

Printed From: TheAMCForum.com

Category: The Garage

Forum Name: Transmission & Drivetrain

Forum Description: If it's between the engine and wheels, it goes here

URL: https://theamcforum.com/forum/forum_posts.asp?TID=41345

Printed Date: Apr/18/2024 at 7:23am

Software Version: Web Wiz Forums 12.03 - http://www.webwizforums.com

Topic: Borg Warner M12 for performance

Posted By: WesternRed

Subject: Borg Warner M12 for performance

Date Posted: Jul/11/2012 at 6:39am

|

Ok, i know everyone is going to say just upgrade to the torqueflyte or turbo 400, but what really is wrong with the M12 as a mild/moderate performance trans? I know parts for it are hard to come by, particularly any sort of performance upgrades but if you can get the Ford FMX to handle 500+ HP why can't the M12 do the same given their shared heritage? Surely for a mild performance street/strip engine, mine is closer to 350HP, the M12 or maybe even the M11 should be more than adequate and avoid the additional work and expense of swapping over to one of the other two.

|

Replies:

Posted By: jackdk

Date Posted: Jul/11/2012 at 7:19am

|

I have no problem with my M12. I'm in the 350+ hp range, and it shifts hard. Continental Converters built me a 10" 2500 stall torque converter for it, and she really does the job. Big thing with BW is keeping them cool, so add a trans cooler to it. We also are running synthetic tranny fluid in it. From what I understand, the M11 is pretty weak for any type of higher HP and will not hold up. ------------- 69 BBG AMX #09007 "If it's to loud! Your to old!:" jax-AMXpress@msn.com AMO #1945 |

Posted By: 69amxman

Date Posted: Jul/11/2012 at 1:12pm

| i had a 325 hp in front of a m11 with a 2000 stall and modified valve body , with no problems what so ever , i have since installed a 5 speed only because i like shifting |

Posted By: 0069X

Date Posted: Jul/11/2012 at 3:42pm

|

The AMC mechanic told me the most important thing to do with the B.W. in my (then new) 69 390 AMX (if I was going to take it to the drags) was keep the bands adjusted, and clean fluid in it. So I always did. After 40+years, it still put's the car sideways when it shifts into 2nd. gear.

|

Posted By: WesternRed

Date Posted: Jul/11/2012 at 7:06pm

Would be real interesting to know what the valve body mods are, one of the problems is there is no shift improvement kits available for these things although you can get them for the FMX, but I imagine the valve body is different. I'm led to believe that the FMX clutch disks are the same, seems like you can get better ones for the FMX. |

Posted By: 348AMX

Date Posted: Jul/11/2012 at 7:33pm

| The m12 has more clutch material than the M11, that is another advantage. A big air cooled transmission cooler mounted up front works very well. The engine fan will continually pull air through it I credit this more than anything to my M12 working so well for so long....that and the guy that rebuilt it really knew the old school transmissions well. |

Posted By: WesternRed

Date Posted: Jul/11/2012 at 7:42pm

|

Check 1, add tranny cooler. When you say the M12 has more clutch material, is that more surface area per disk or more disks, I thought they both used the same rebuild kit or are we talking about the bands? |

Posted By: 1970390amx

Date Posted: Jul/12/2012 at 12:58am

Although I cant prove it just yet I believe the m11 and m12 are basically the same trans. A m12 has more clutches than a m11, making it a heavier duty transmission. From going through some parts books I have and comparing part numbers for fmx and m12 transmissions there are clutch parts and bands from various fmx years that interchange with m12 parts. Yes there are some performance clutches and bands avalable for fmx transmissions. As far as valve body mods the first thing I would do is make sure the transmission is running the max line pressure it should have or maybe a little more. From what I can see the converter hub is a weak area also, I have read that a ford hub can be put on the amc converter allowing one to use a fmx pump on a m12. ------------- 1970 390 4speed Bittersweet shadow mask AMX 1970 Amx missing most everything, or in a box |

Posted By: WesternRed

Date Posted: Jul/12/2012 at 1:21am

|

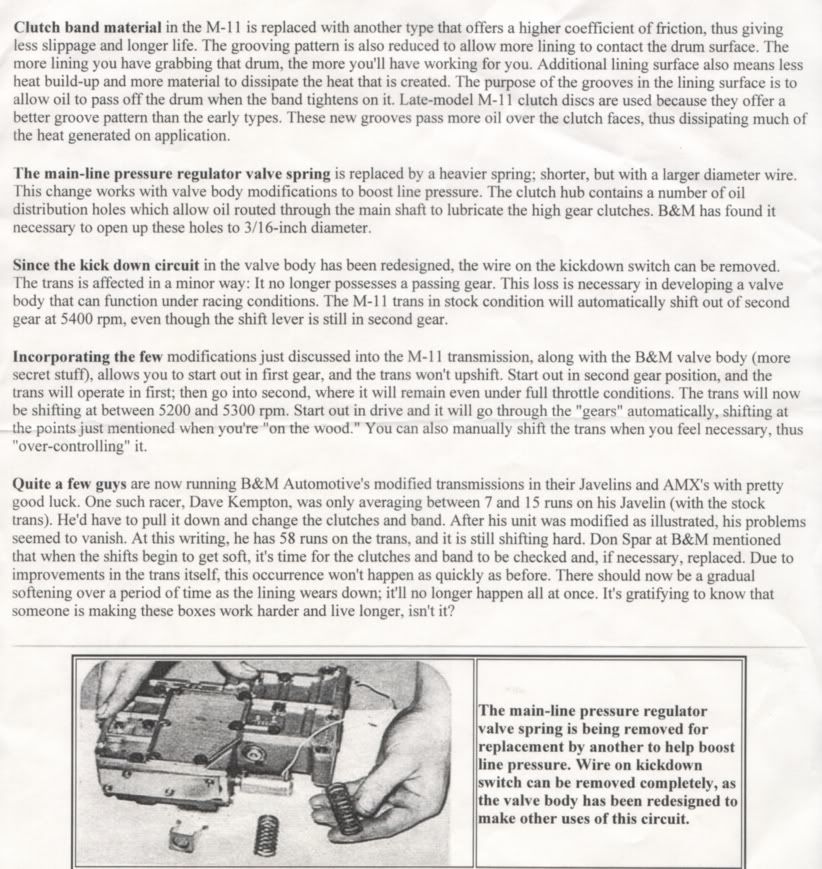

I found an old article from Hot Rod magazine back in 1969 that covers some mods by B&M to the Borg Warner trannies so might as well link it up here: http://www.australianjavelins.com/media/toughening_borg_warner_m11_m12.pdf" rel="nofollow - http://www.australianjavelins.com/media/toughening_borg_warner_m11_m12.pdf This covers the issue with the convertor snout weakness, too much lash, and B&M's solution to fixing it. I'm in the process of pulling the M11 out of my car and will them be able to do some direct comparisons with the M12 I have here that I stripped down the other day.

|

Posted By: WesternRed

Date Posted: Jul/12/2012 at 5:02am

|

Ok have the two trannies apart, the one from the car has 11-1 cast into the top of the case, AS11-16 on the tag and one bolt holting the front band servo so this one should be the M11. The second tranny has 12-1 cast into the top of the case, can't read the tag so don't know what is on it but it has two bolts holding the front band servo so this should be the M12. Both have 28 spline output shaft. Besides the number of bolts holding the front servo I can't really see any other internal difference, same diameter and number of friction and steel clutches in each, same band diameter and width. I'm not sure what to think now.

|

Posted By: WesternRed

Date Posted: Jul/12/2012 at 11:07am

|

On closer inspection the piston in the front band servo of the M12 is much larger in diameter and the servo arm is a little different. Seems like the changes are all about improving the effectiveness of the front band servo. Did a bit of measuring and counting, the clutches are more or less the same as those in the Ford FMX.

|

Posted By: madmax

Date Posted: Jul/12/2012 at 11:59am

|

main difference between 11 and 12 are the band servos. be carefull when buying clutches, there are many different thicknesses of the clutch and steel plates. bw 11/12, fmx, cast iron med case ford are all basically same,they will all fit in the drum but you need to make sure they stack to the correct clearance. also some have cushion steels and some are flat. also not all the gasket sets are the same. make sure you get a bw12 kit. you can use the fmx front band with a different strut kit. not any valve body kits that i know of, i usually set my clutch packs at the bottom side of tolerance and the shift very well. on race ones i change out the cushion steels for flat ones and use appropriate thickness clutches to get the right clearance. if they are still availible they used to sell brass clutches for the med case ford. only use these in the forward drum. i have had a bw 12 in my old street strip amx, ran low 12s and used nitrous a lot in the mid low 11s. drove it all the time for 5 years no problems. hope this helps. if you need help with getting the correct parts shoot me a pm and i will be glad to help. thanx rick ------------- American Heavy Metal restoration parts and mechanical restoration services 70 amx black 1968 kaplan amx ss/racecar 1969 amx racecar 1970 trans am javelin 1969 amx white/platinum 1972 gremlin |

Posted By: WesternRed

Date Posted: Jul/12/2012 at 9:40pm

|

Thanks for the great info Rick. Seems like parts for the FMX are even getting hard to find these days. This is about all I could find in the way of clutch frictions and steel plates.  I haven't seen any rebuild kits specifically listed for the M12, they all have the application as M11/11B/12 so one would hope there are extra bits in there to cover any differences between them. In my case what I have is a M11 that has toasted the front band and scored the drum and a M12 that has been laying around in somebody's paddock for years and has a bit of water damage in a few places. Plan of attack would be to do a rebuild using the case, servos and front drum from the M12 and probably everything else from the M11 if that would work? The M11 is from a console shift car and the M12 has the shift lever pointing down so I'm assuming it's from a column shift car. I believe the valve body from the floor shift car would be the one to use because it allows more manual control of the shifting aka the "Shift Command" feature. I don’t know if there are and differences between the M11 and M12 valve bodies that would work against this? Hopefully when I get the engine and diff sorted I can crack into the 12’s that would be the plan. Going a little bit of the rebuild side of things the only other thing on my mind is if I can use something other than the factory dipstick tube, which is a real pain with headers? Maybe drill the case to take a Lokar setup of some sort? |

Posted By: amcenthusiast

Date Posted: Jul/16/2012 at 3:21pm

|

This is an edited post, because I would seriously like to avoid conflict with Farna, with whom I've been having conflict in this regard for at least twenty years -to defend the history of these American Motors 'Borg Warner' units. So... I came back, and changed my comment to read as following: one easy hop up tip is to adjust the throttle cable or vacuum modulator to raise the mph shift points (the throttle valve inside the valve body has a direct effect upon main line pressure; 'raising the shift point' also raises the MLP) the next easiest hop up tip is to adjust both bands '1/4 turn tight' (I learned this from a 'Trans Go' info pak that came with some parts I bought to rebuild an AMC 904) the way to do this is to simply follow the directions in the AMC TSM or rebuild manual on how to adjust the band (snug up the set screw then back it off to the specs quoted in the book) then turn the set screw 90 degrees tighter from there > what this does is it reduces the time it takes for the band to apply and release during a shift change (reduces 'slip time' on the band) -this'll make the trans shift quality feel more firm... ...and along with the raised main line pressure caused by re-adjusting the throttle valve mechanism (cable or vacuum type) making both these adjustments work together to make the trans have a more firm shift quality/'feel' -performance wise- this reduces the time it takes to make a gear change and it reduces the amount of slip (on the clutches and the bands) for better durability *best thing about it is you don't have to buy anything -just make the adjustments & that 'firms up' the transmission ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: jackdk

Date Posted: Jul/16/2012 at 3:35pm

|

That's some good info AMCFAN! I'll have to keep all this stuff in mind, and the next time at the shop, have them tighten the bans 1/4, and boost the preasure. I like hard shifts! ------------- 69 BBG AMX #09007 "If it's to loud! Your to old!:" jax-AMXpress@msn.com AMO #1945 |

Posted By: farna

Date Posted: Jul/16/2012 at 4:55pm

|

Good, BUT there are some errors. I've got an article about the BW/Ford/Studebaker connections somewhere... dated around 1952. Detroit Gear was either a subsidiary of Borg-Warner or BW bought DG in the early 50s. Not sure on that part, but the DG auto became the BW. Studebaker started having financial problems in the early 50s and Ford joined the fray, probably through connections with BW (they had been buying BW T-85s with ODs, and a few other manual trannys). Don't know what the deal worked out between Ford and BW was, only that they shared some development. Ford has always cast their own main cases and valve bodies, and they don't interchange with BW counterparts, but the main rotating assembly DOES interchange... mostly. Might be some minor differences, such as splines on the output shaft (or even internal splines), but most internal parts will interchange. I was going to mention changing the main regulator spring, but I see that's in the posted article. That's a great PDF file to have on hand! ------------- Frank Swygert |

Posted By: amcenthusiast

Date Posted: Jul/16/2012 at 9:12pm

|

I deleted this comment, to remain polite to Farna. I have no burning desire to embarrass anyone here on AMC Forum. Thank you for your insightful understanding.

------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Jul/17/2012 at 12:13am

|

Perhaps I can contribute to this AMC community by adding another perspective. Studebaker and Jaguar used the Detroit Gear automatic trans for a certain period of time. They look like this: '61 Jaguar DG-250 Tag looks like this: (teal colored tags indicate BW LTD = made in England) Here's a Stude DG 250: Here' the tag (red indicates made in USA... this tag must be faded?): Here's a Jag DG 150 (aircooled): Here's the tag: here's a quick pic of the 'three band' DG-250 internals: for comparison, here's a pic of my '65 AMC Warner Gear 10B:  here's the tag (red indicates made in USA, but I owned one Marlin which had teal tag AM WG 10b saying 'LTD made in England')  MYTH BUSTED, CASE CLOSED. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: WesternRed

Date Posted: Jul/17/2012 at 5:46am

Great info guys. The only thing with the pressure regulator spring is that the old Hotrod article I posted doesn't give any specifics as the idea would have been to buy the B&M bits back in the day:

Would be a bit of trial and error to get something that gives the desired effect I reckon. Those FMX shift improver kits are pretty cheap might just grab one on the off chance that some of the bits work. I did find someone over in Sydney who can re-line the bands for me, so that a little bit closer to home than sending them to the US. They suggested I might want to use Kevlar linings if I am planning a bit of abuse, don't know if there is any downside to this. The guy did say that it was very important to deglaze the drums otherwise the new bands would tend to slip and would not last very long. Amcenthusiast, you might have to work on your links and pictures, try the little tree symbol at the top of the window to insert a picture. Not sure what is going on with the amccf website from Finland, seems you can only link up the main page. |

Posted By: farna

Date Posted: Jul/17/2012 at 6:49am

|

BW was the major developer, I don't know if Ford just fed them money or had an active part in development. As far as patents go yes, BW holds many (if not all) the patents, but I'm sure they used some from the by then expired Hydramatic (first appeared in 1939, preproduction pilots tested 35-36, so patents would have been late 20s/early 30s). As to Ford manufacturing, it would all depend on what kind of agreement they had with BW. It looks to me like they had some sort of license manufacturing deal where Ford made their own cases and valve bodies (at least later made the VBs) but purchased some internal parts from BW. A few of the internal parts of pre FMX Ford models have BW on them, according to some tranny people I've talked to. The FMX was the last BW based trans Ford made and appears to be mostly Ford produced, even though many components still interchange with later BW models.

------------- Frank Swygert |

Posted By: WesternRed

Date Posted: Jul/17/2012 at 8:21am

|

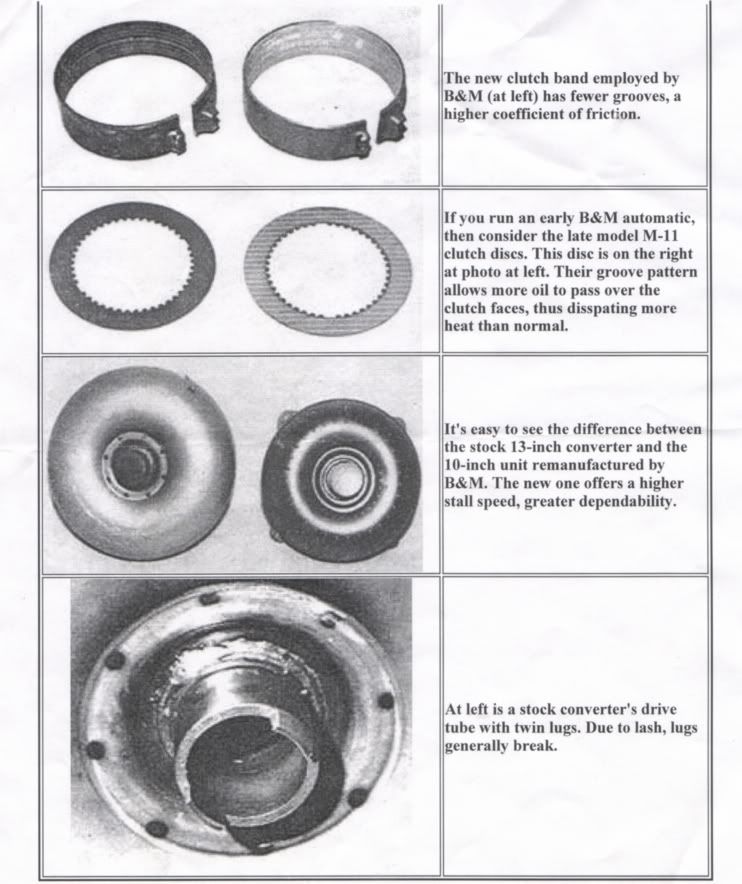

Valve body on the FMX is completely differnet as I think someone already suggested, just for the record: Borg Warner M11  Borg Warner M12 (you can see the extra bolt holding the front band servo)  Ford FMX  |

Posted By: farna

Date Posted: Jul/17/2012 at 9:05am

|

The FMX is more like the older M-8 and M-10. There are still some obvious differences, but the resemblance is obvious. By the time the FMX came out Ford was making their own design transmissions. Makes you wonder why they even continued with the BW design. Maybe their agreement with BW extended out to a certain year/dollar amount/production quantity. Normal in the automotive world -- that's why Chrysler continued selling the Renault Medallion a building the Eagle Premier a couple years after purchasing AMC from Renault.

------------- Frank Swygert |

Posted By: amcenthusiast

Date Posted: Jul/17/2012 at 6:25pm

|

I deleted my excessively long comment to discontinue arguing with Farna. Here is a good link to 'Trans Go' showing a variety of valve bodies that were used in the Ford-O/FMXs http://www.transgo.com/CastIronFordValveBodyID2.pdf" rel="nofollow - http://www.transgo.com/CastIronFordValveBodyID2.pdf Perhaps this will help figuring out how to adapt Ford-O/FMX shift kit parts. An assortment of AMC Warner Gear automatic springs are described more fully in the AMC TSMs. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: WesternRed

Date Posted: Jul/17/2012 at 7:16pm

|

For any other Aussies the place in Sydney that offers the band re-lining service is Transbands/Advanced Friction: www.advancedfriction.com.au They quoted less than $100 to reline both bands in Kevlar, which I thought was pretty reasonable. The front band out of my M11 is down to the metal but the M12 ones actually looks ok but I think I would just prefer to get it redone. Both rear bands are a bit suspect, one has couple of black strips and the other has a little bit of metal showing. Going back to beefing up the main pressure regulator spring there is an old mod for the BW35 series known as the 1 cent shift kit, I believe this probably involves increasing the line pressure by shimming the spring with a 1 cent coin, not sure what the US equivalent would be. Maybe this approach would be safer than trying to guess what other spring might do the job? |

Posted By: 348AMX

Date Posted: Jul/18/2012 at 10:51am

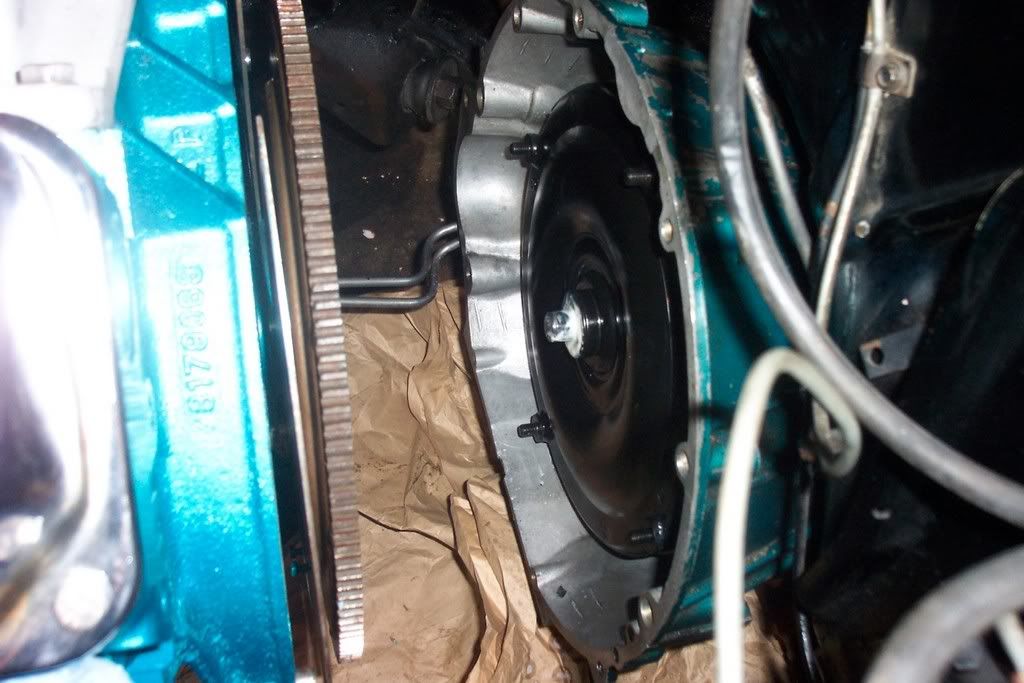

Here is a good article about building the M11/M12 for performance use. It gives a lot of good info on the weak points and how to address those weak points and make the transmissions more durable and harder shifting. VERY straight forward and no voodoo involved just basic old school modifications proven to work well that any good trans mechanic can do.   Here is my modified dipstick/pan to clear any headers I might want to use, gives lots of clearance for my full length hooker supercomps.  My continental 11" 2500 stall BW12/11 hi po converter installed on my 343  and gettting bolted in after install on the ouptut shaft of the M12. It was a perfect fit.  |

Posted By: jackdk

Date Posted: Jul/18/2012 at 12:27pm

|

Great articale 348AMX. Thanks for posting, and Contental also put a 2500 stall, 10" converter together for me. Only problem is, I still drive through the cruise night parking lot with my foot on the brake to keep from running over people. I thought the higher stall would stop that, and it would almost be like slipping the clutch with a 4spd car.

Tell me more about the tranny pan/dipstick mod. What did you do? We cut a piece out of the elbow to tighten the angle. It helped, but is still right against the collector of my Super Comps for about 4". Now my tube is beginning to seep where we made the weld on the tube. Theres got to be a better way.

Thanks,

Jack ------------- 69 BBG AMX #09007 "If it's to loud! Your to old!:" jax-AMXpress@msn.com AMO #1945 |

Posted By: 348AMX

Date Posted: Jul/18/2012 at 3:47pm

The dipstick tube is a problem with headers. Hooker used to have install instructions with their headers to do exactly as you did; cut a 1" or so section out of the tube to reduce the curve length of that bend where it comes out of the pan. The problem with that is the dipstick ends up further down into the pan and it will read high. The transmission builder that worked on my M12 for my AMX simply welded up the hole for the original dipstick bung and moved it over towards the front of the pan and away from the header collector flange, and welded it back on. This keeps the dipstick tube the same length and did not affect transmission fluid level readings. The bend in the tube is about 1" away from the header collector, but I wrapped the collectors in header wrap to eliminate the heat from the header collectors from transfering to the pan and boiling the fluid...and that worked great. One thing that is very important with the dipstick tube is to have the bracket that secures it to the head at the exaust bolt or the valve cover bolt. I made my own bracket and secured the tube to a valve cover bolt. If you dont secure the tube the nut at the pan on the end of the tube will eventually vibrate loose and drip transmission fuid......ask me how I know! I had removed the bracket to install factory valve cover painted AMC blue, but I left my bracket off, I wasnt driving the car but after a few times backing the car in and out of the garage into the driveway and running it, the nut loosened and while it sits in the garage transmission fluid pools all over the floor under the car from that fitting. Bracket will be going on before I start driving the car regularly again next year with a fluid change and new pan gasket....and a big clean up of the garage floor under the car....looks like its bleeding to death LOL! As for your idle, have you set up your intial and total timming curve?? Less intial and a slow curve will force a higher idle to prevent stalling. |

Posted By: jackdk

Date Posted: Jul/18/2012 at 5:16pm

Thanks for the info. I am far enough ahead of the collector flange, (about 2"), the tube is closer than I like along side the collector pipe, (about 1/2"). If I move the bong forward, then the tube will run into the wider part of the collector pipe where the 4 exhaust tubes come in, as its doing now for about an inch. This is where its tight against the exhaust. When we tightened the curve on the elbow, we still had the correct horizontal position, and measurement on the dipstick. As all we did is alter the elbow, and not the position of the tube itself.

I DO need to find a bracket, as I don't have any on there at the moment. Maybe that's why I had a few drops on the floor when I got home from the cruise the other night. Nice thing about an epoxy floor! It just wiped up with a rag. Maybe I'll run a "wanted add" for extra dipstick tube and bracket...

Thanks again... ------------- 69 BBG AMX #09007 "If it's to loud! Your to old!:" jax-AMXpress@msn.com AMO #1945 |

Posted By: WesternRed

Date Posted: Jul/18/2012 at 8:15pm

|

348AMX, thats a great article, same one I linked on the first page. Covers the torque convertor, improved friction materials and increasing the line pressure but there is mention of other valve body mods that they have chosen to keep secret, after all B&M wanted you to buy their products. Any idea on the price of a convertor from Continental? I can get my factory one "improved" locally but it seems a smaller one might be a better option. This is what I did with my dipstick tube:  But in the end it still wound up hard against the collector so it would be nice to find a better solution. I did add a bit of insulating sleeve to try to minimise heat transfer:  |

Posted By: jackdk

Date Posted: Jul/18/2012 at 9:16pm

_________________________________________________________________________

I got mine from Contenental about a month or two back WesternRed. It was built special for me with the built 390, 3.54 gears, and 26-1/2" tall tires. It was $717.00 shipped to the house. Nice people to work with. I talked to Peter. Great, helpful guy... ------------- 69 BBG AMX #09007 "If it's to loud! Your to old!:" jax-AMXpress@msn.com AMO #1945 |

Posted By: 348AMX

Date Posted: Jul/18/2012 at 11:02pm

| IIRC mine was 650 but that was 4 years ago. |

Posted By: WesternRed

Date Posted: Jul/18/2012 at 11:19pm

| Thanks guys, I dare say delivery to aussie will add quite a bit to the price. |

Posted By: amcenthusiast

Date Posted: Jul/21/2012 at 3:48pm

|

I deleted my long comment here to save space on AMC Forum ...to be 'nice'. I must have said something about 'bronze frictions' since they are alluded to in the next comment. As I understand it now, based upon many years of study, since I first began rebuilding these units back in the mid-nineties, the bronze frictions are basically become a 'thing of the past' because... 1) EPA rules and regulations have 'put the squeeze on' many metal manufacturing businesses for the amount of 'run off' toxic waste in our public water systems. 2) Copper is directed by the artful use of law, into the production of 'high tech electronic appliances'. (where 'law' is essentially the same as 'EPA rules and regulations' ...which are enforced, as if, they are 'real' laws!) (but the are not: they are 'rules and regulations' made by employees, not actually by our elected officials who hold office and have the authority to pass bills and make real laws!) Wherefore, copper is become higher in status due to the government action to increase the 'high tech industry'. (for more products to sell, to more people, to collect more taxes, to become more wealthy, to rule the world etc etc!) The government is in the business of 'economic stimulation'. They are doing their best to do a similar thing with every other commodity, like 'plastics' (petro-chemical industry; major source for plastic is natural gas) In so many words, this is the reason we see bronze lined friction plates fade into oblivion. -The whole world needs copper wiring to cover the earth with electrical products instead. ---------------------------------------------------------------------------------------------- Anyway, back at the ranch... Why do I say 'bronze frictions are good'? (I've studied this topic for at least twenty years) 1) Bronze lined clutch friction plates offer the best heat transfer; plate to plate, within the clutch drum assembly. -Where any other type of material works more as an insulator instead/works against heat transfer, not transferring heat out of the friction plate nearly as well. -where excessive heat is the enemy of any automatic transmission. 2) Information broadcast from the makers of bronze bushings clearly insist that bronze-to-steel is among the very best, most durable combination to resist wear -having a very low 'coefficent of drag' when bronze is used for bearing surface on steel. Hence, a bronze friction plate will last longer than most any other material -where the plates 'rub' on steel drive plates inside the clutch assembly. Note: Friction plates, inside the automatic transmission, can be conceptualized in analogy to them being like 'brake shoes' = they are like the 'disk brakes' on your car; they 'grab and release' by hydraulic action very similar to 'disc brake pads' -Note: High performance disc brake shoes are called 'semi-metallic' = flakes of metal are added to the friction lining on the brake pads to improve the heat transfer, in order to reduce 'brake fade'. -Hence, the analogy is altogether insightful: bronze frictions (are the obvious superior choice to) reduce 'brake fade' inside the clutch assembly, by offering superior heat transfer capacity. -they'll last longer, and the transmission will run cooler. The argument against running bronze frictions: When they wear, they shed micro metallic particles into the ATF & those tiny particles can interfere with the smooth operation of the unit's precision made hydraulic valve mechnaisms (in the 'valve body') -but 'paper' frictions don't... ...however, the particles of 'paper' must go somewhere: they don't just vaporize; they go into the ATF also, adding a trace amount of insulative/non-heat transfer properites into the oil mixture... The same concepts apply to (pun intended) any other type of brake shoe material: where does the 'off-scouring' go? It's absorbed into the ATF, in an auto trans-brake application. Note: The same can be said for the 'bands': they are just like 'band brakes' on a go-cart (they are 'band brakes' in reality, inside the transmission though) -The 'ATF' is basically hydraulic fluid dyed red for automotive application (highly complex chemistry of modern auto trans fluid additives and composition is another technical discussion) Side note; GM's Hydromatic first used 'whale oil' for it's hydraulic fluid ...and whale oil, was used for 'lamp oil' and this is why the GM Hydromatic factory fire was so horrific; whale oil is very flammable -why it was used for lamp oil. In fact, around mid-fifties, 'Type A' was basically whale oil dyed red, while the petro-chemical industry learned to make the same type of fluid from 'crude oil' by refining processes. (I think I said that right/close enough I guess) SO that's basically 'it' in a nutshell: Think of the clutch frictions and steels as if they are disc brakes, but in a fluid bath of ATF. Where car makers make millions of cars, instead of millions of transmissions using bronze frictions, that same amount of copper content has gone into the 'high tech industry' instead. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: WesternRed

Date Posted: Jul/22/2012 at 11:35pm

|

The only questions I have is where to get the bronze plated frictions? Any downside with running them? Are the clutches really the issue? Going by my experience with only one M11, so in no way conclusive, it was the front band that burnt out and this appears to be the main area of improvement in the M12. |

Posted By: farna

Date Posted: Jul/23/2012 at 5:50am

|

Well, it's easy enough to get the front band relined with better material. I'd think the main cause of burning the front band would be adjustment though. Depends on how fast it burned, and how many miles were on it when it did. Too loose or too tight -- either will make short work of a band.

------------- Frank Swygert |

Posted By: WesternRed

Date Posted: Jul/23/2012 at 6:28am

|

Well, i would say unknown history, lack of adjustment and probably low oil were probably contributing factors plus a few trips down the strip with the bigger, better engine. Hopefully the re-lining is under control, just need to sort out the rest of the rebuild to improve it's chances of survival in the future. The aussie distirbutor for Alto has both the fixed and mobile phones disconnected so that is not a good sign.

|

Posted By: WesternRed

Date Posted: Jul/26/2012 at 4:26am

|

Still looking for a source for some performance type clutches for this thing if anybody has any ideas? As far as the brass ones go the only brass lined clutches I can find are for Borg Warner Velvet Drive marine transmissions.

|

Posted By: farna

Date Posted: Jul/26/2012 at 1:38pm

|

The clutches should interchange with Ford FMX, if that helps any. I did say "should". I've been told that they do, haven't tried it.

------------- Frank Swygert |

Posted By: WesternRed

Date Posted: Jul/26/2012 at 2:25pm

|

Unfortunately that doesn't really help because I haven't been able to find anything for the FMX either. Despite Alto apparently listing clutches for the FMX in their catologue, nobody seems to sell them. The Ford guys all seem to go for either the C4 or C6 rather than the FMX, probably because performance upgrades for these boxes are readily available. Anyway got my bands back yesterday so things are starting to move:  |

Posted By: Lucas660

Date Posted: Jul/26/2012 at 6:13pm

|

Try Alto direct, they should be able to steer you in the right direction.

16 Haven Place George Jacklyn |

Posted By: toolmanxiii

Date Posted: Jul/26/2012 at 7:11pm

|

"BW was the major developer, I don't know if Ford just fed them money or had an active part in development."

Look up Carroll Shelby and Ford . And from what I have read Borg Warner Did All their own research with the help of may racing teams over many years http://en.wikipedia.org/wiki/BorgWarner" rel="nofollow - http://en.wikipedia.org/wiki/BorgWarner ------------- 71 360 Hornet sst 83 2wd 360/727 Eagle wagon (crashed) |

Posted By: toolmanxiii

Date Posted: Jul/26/2012 at 7:13pm

|

Sorry I like to know as much as I can about any part of an AMC . ------------- 71 360 Hornet sst 83 2wd 360/727 Eagle wagon (crashed) |

Posted By: WesternRed

Date Posted: Jul/27/2012 at 10:55am

|

Lucas660, those numbers were a great help, direct link straight to the source, just had to wait until the middle of the night to call them. Anyway, according to the very helpful girl in the tech department the clutches and steels for the M12 and FMX are the same part numbers. So just for the record the following parts are apparently readily available: P# 49740 - Red Eagle Friction 0.061" P# 49742 - Red Eagle Friction 0.080" P# 49700 - Bronze Friction 0.061" (this is the only thickness available in bronze) P# 23701 - STD Steel Plates 0.068" (flat plates for front clutch pack) P# 23703 - STD Steel Plates 0.065" (dished plates for rear clutch pack) P# 23701K - Kolene Steel Plates 0.068" (flat only) So hopefully that covers it. |

Posted By: 348AMX

Date Posted: Jul/27/2012 at 2:23pm

| ^^^awesome research there! Now are those considered high performance or just stock replacements? |

Posted By: WesternRed

Date Posted: Jul/27/2012 at 3:48pm

|

The Alto Red Eagle clutches and Kolene (hardened) steel plates would are probably the most well known brands in the performance transmission world and a few people on here have also suggested using the bronze clutches. Alto also makes the regular steel plates and various other OEM replacement type clutches. I did enquire with one of the other online vendors and their rebuild kits used Borg Warner clutches, which they said were good quality and would stand up to performance use. I reckon the run of the mill friction materials would have probably improved substantially in both performance and durability in the last 40 odd years. |

Posted By: bvpotash1

Date Posted: Jul/27/2012 at 6:08pm

|

Just my 2 cents about bronze clutches. Many years ago I rebuilt the tranny out of a late 50’s Lincoln. It was an early FMX with bronze clutches that were original. I rebuilt it with modern friction clutches. The owner told me he had never felt the transmission shift until I rebuilt it. The original unit was not burned up but had a cracked case that I replaced. That tells me that the bronze clutches don’t engage as hard or as soon as the modern friction linings do. I don’t think that bronze is the way to go for performance applications. Like I said, just my 2 cents. |

Posted By: amcenthusiast

Date Posted: Mar/14/2016 at 1:42am

|

what affects shift firmness is line pressure if you can't 'feel it', the line pressure is low (yes; that's true what the other man said about the 'cupped steels' in the 1-2 clutch- they made that clutch grab softer and they can be replaced with 'flat steels' (used in the other clutch, in OEM applications) & then the clutch pack needs to be re-sorted for the correct clearance as prescribed by the overhaul manuals...) AMC TSM shows how the throttle cable or vacuum modulator adjustment affects main line pressure. ------------------------------------------------------------------------------------------------------------------------------ Edit here for any other casual reader of this thread: The old article showing the B&M modifications says the AMC two prong type torque converter engagement is prone to breakage. (due to slack in the engagement or whatever) This is NOT true. (BALONEY!) The reason why is this: all that engagement does is drive the oil pump. There can be no back and forth 'slack' in the engagement because the engine only turns one direction! Hence, the transmission's oil pump is only driven in one direction!* When we downshift the transmission, that does not place force on the oil pump drive; that transfers force through the input shaft into the torque converter (NOT the oil pump drive mechanism) Hey! If your engine is turning the wrong direction... you've got more than transmission trouble! The two prongs only need to withstand the amount of power it takes to drive the oil pump, which is a small amount ...like about 4 to 10 hp, estimating 1 hp per every 10 psi -similar to what it takes to drive the oil pump in the engine (typically driven by the distributor drive gear through a shaft to the oil pump) Moreover, the B&M 'AMC Borg Warner hop up' article shows the FMX torque converter hub and says its stronger... Rather it's the opposite: the two machined flat surfaces that are intended to engage and drive the transmission's oil pump ring gear will tend to 'wedge' the oil pump ring apart instead (assuming there is a 'heavily loaded' condition, which there is not) So, even though the FMXs' torque converter engagement design is actually weaker, still, there is not enough strain there to worry about = it's basically a 'non-issue' ...whatever... *There are a few internal component parts that spin in the opposite direction, when the unit is downshifted, to give engine braking (for resistance against engine rotation) The transmission's oil pump however, is not one of them. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: farna

Date Posted: Mar/15/2016 at 7:43am

|

Detroit Gear (a division of BW) originally made the auto in cooperation with Studebaker in the late 40s/early 50s. As Stude got into financial trouble it had to back out, and Ford stepped in (around 53). The deal between Ford and BW was that Ford got production rights, and would buy 50% of their auto trannys from BW for a number of years (though the mid 60s... 10 years IIRC) in exchange for those rights. The Ford trannys were made slightly different form the ones BW supplied others, but just the valve body and the main case. All the machined rotating parts were shared. That's why the rebuild kits apply to Ford and other BW trannys, and have different pan and VB gaskets. I researched this for a magazine article some years ago. Part of it used to be on the BW site under history, but that has long since disappeared. ------------- Frank Swygert |

Posted By: farna

Date Posted: Mar/16/2016 at 6:19am

|

Oops! Someone made (and apparently deleted) a post stating the Ford-O-Matic appeared in 1950, not 1953 as I posted. I checked -- correct!! Actually 1951 model cars, but would have been made in late 1950... I think the article I have from one of the "science" mags on the BW/Stude/Ford trannys (it's titled "The New Automatics" or something similar) of the 50s is a 52 or 53 issue... may be 51. Haven't looked at it in a while! http://en.wikipedia.org/wiki/Cruise-O-Matic" rel="nofollow - https://en.wikipedia.org/wiki/Cruise-O-Matic This article states that Ford was to buy 50% of their trannys for five years, not ten. Not verified, could be either, but I'm going strictly from memory and may be wrong. Not sure when it started either, but shouldn't have been into the 60s... even 10 years would have ended in 60 or 61 since production started in 50/51. ------------- Frank Swygert |

Posted By: rsrguy3

Date Posted: Feb/02/2020 at 11:04am

|

What's the most recent m12 rebuild anyone here has done? Would you have a solid up to date list of currently available parts and suppliers (a-z) friction, steels, gaskets etc. So far I'm lost at sea. Also what difference to wear and drivability do high performance parts make? Steels, bronz that sort of stuff? ------------- javguy |

Posted By: amx007

Date Posted: Feb/03/2020 at 7:59am

|

My friend owns a shop and he’s a gear head he rebuilt mine he crossed over everything he needed to set it up, nice I burn rubber it’s on a 290 in my amx and ill tell you what he set up passIng gear and the lights in shifter it’s done like it should be a competent builder should be able to go through one and bring it back to specs or more my m12 came out of a machine ------------- dream red white and blue 1968 Chicago auto show amx 290 4 speed 1969 driver Amx 290 auto |

Posted By: farna

Date Posted: Feb/04/2020 at 5:50am

|

Performance steels, clutches and bands generally last longer, especially if the trans has been reprogrammed to shift firmer. Auto trannys are programmed from the factory to slip a bit between gear shifts. This makes for a nice smooth and light shift. They will shift a bit harder as you speed up -- the vacuum modulator or TV cable controls internal pressure, so there is more pressure as there is more load placed on the trans. That can be adjusted to firm up the shifts a little, but you can only do so much there. On the BW design you can shim the shift accumulators so that they "hit" the servos and clutches a bit harder. This can be done with washers -- one or two under each accumulator spring. You may have to pull the valve body a couple times before you figure out how much shimming is good for you. Note that performance bands can wear the surface of the drum more since they are a bit more aggressive than stock. Any extra wear should be minimal, but it's there. Same with the clutches, but the steels between the clutches take a lot of the extra wear, so not as noticeable in the clutch packs. Using good trans fluid and keeping it cool minimizes wear. The cooler in the bottom of the radiator isn't enough! Even a small cooler added inline with the built in radiator cooler works wonders! I always run through the radiator cooler then the added cooler, or skip the radiator mounted cooler altogether (with a medium or large external cooler).

------------- Frank Swygert |

Posted By: WesternRed

Date Posted: Feb/04/2020 at 6:10am

I just finished using a kit from here: https://www.transpartsonline.com/TRANS_PARTS_FILE/tpcat.php?TransPartsOnline=BW12&TransPartsType=BW12" rel="nofollow - https://www.transpartsonline.com/TRANS_PARTS_FILE/tpcat.php?TransPartsOnline=BW12&TransPartsType=BW12 Which is Vista Transmission

Parts 2244 S Santa Fe Ave Unit C15 Vista, California 92084 I bought the kit without the steels only to find that mine were burned up in the rear clutch pack when I pulled the transmission down. Sourced new steels from a local supplier in Australia and also had the bands re-lined by another local supplier. The front band is impossible to source as a replacement item, although you might find the rear band as they are the same as some of the Ford ones, mine already had a Ford band in it. I have so far not had to replace any hard parts like bushes and thrust washers. PS: I have given up on performance mods to this transmission as reliable information on what to do just doesn't exist. You might be able to get some performance frictions or even brass ones and that is about it unless you want to waste a lot of time experimenting.

------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: rsrguy3

Date Posted: Feb/05/2020 at 9:44pm

|

Turns out my dad's good friend had a contact, he's been doing this forever (transmissions) even designed and built his own for his own winning top alcohol dragster (uses bw/fmx clutches in it) he even built one of the first, if not the first 2 piece modular torque converter. During our talk he flinched when I mentioned no shift improvement kits were made for the m12.... "yes there are" he said "but they're all up here" as he pointed to his noggin... Go figure. Anyway he quoted me a price for a tc overhaul, pump overhaul, total rebuild with re-lined bands and servos for not much more than parts... I think it's one of those my dad's buddies buddy deals, I wish dad was still around to see this all happen. This is why this is such a cool hobby/ lifestyle, guys like Gary and those of you here on the forum, willing to share. It's a huge deal.. for me any way. I've been away from performance street rods for a long time now, it appears I've forgotten almost everything I'd learned. I just hope you guys from my dad and Gary's generation do the best you can to look after yourselves. I for one don't take your influence and guidance for granted. Thank you guys! ------------- javguy |

Posted By: WesternRed

Date Posted: Feb/06/2020 at 1:00am

This is the issue, nothing is really written down and there are no off the shelf options. As somebody else mentioned it can be as simple as a shim under a spring or a slightly stiffer spring, but it is a trial and error process to get what you want. With the Borg Warner 35, we used to refer to a 2 cent shift kit (in Australia), which consisted of inserting a 2 cent coin under the main pressure relief valve spring to boost line pressure and it also only cost you 2 cents. By contrast, if you have a TF727 or any of the other mainstream transmissions, you can just order a valve body to suit your needs including things like reverse shift pattern and even a transbrake. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 10:43am

|

I'm not trying to embarrass anyone here for conveying a false historical record. Mythomania is compulsive lying, which damages the reputation of our favorite American Motors products. We don't need to make up new lies to cover up the old lies; that is mythomania, which is a mental illness. ------------------------------------------------------------------------------------------------------------- That is correct: I have personally done much research to find an actual AMC specific 'shift kit' for our old AM Warner Gear iron case automatic transmissions. If I could find it, I would post a link on XRV8 Race Parts website. -if only to reduce the 'stigma factor' that says 'no; you can't hop up that transmission'. However, what I have found is a handful of springs, in a kit for Ford Cruise-O-Matic, which looks just like the springs that are used in the AM Warner Gear Flash-O-Matic and Shift Command units. Yes: The main pump spring for all these units appears to be identical, and the kits for Ford units typically include a 'higher performance spring' for the (front) pump. -Presumably to increase pump pressure, to increase line pressure, to increase lubrication circuit pressure and overall flow rate ...presumably for increased cooling by increased fluid flow, which doubles as a carrier of heat to the cooling system. The thing about this is, increasing pump pressure, increases parasitic loss by making the pump work harder. And having a lower parasitic loss rating is one of the better, more desirable features of running a Shift Command unit. (Like FMX, Shift Commands have no rear pump) (the earlier Ford-O-Matic, Cruise-O-Matic and Flash-O-Matic units have a rear pump in order to push start the car! -something that faded away through the evolution of more dependable electrical charging systems/the alternator, replacing the older generator systems) I'm still working on this aspect, but from my perspective, what I would like to learn is how to restrict pressure (or reduce pressure) to the 'reverse circuit' -to prevent a 'reverse clunk' on a higher rpm (hopped up) idle type engine. (my Rambler V8 idles at about 1000 rpm with it's custom made independent runner intake system, and it makes a hard 'clunk' when shifted into reverse: if I adjust my line pressure higher to get firm/hard shifts, then the reverse makes a more severe 'clunk' and vise-versa) ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 12:22pm

|

I have the links to Alto parts, with some of the associated information on my XRV8 Race Parts website. One of the reasons why I keep them posted there, is to keep them 'separated' from the usual bulloney type information: I can control the text on my pages, but I can't control the random sayings other people post on other websites... I'm less interested in disputing myths, than I am interested in simply posting good hop up information. -In order to (hopefully) do my part to repair the damage done to the reputation of our favorite cars. --------------------------------------------------------------------------------------------------------- That said, concerning this discussion named 'Borg Warner M12 for performance' here on AMC Forum: 1) The highest high performance example AMCers have for this unit is '67 Grant Rebel SST Funny Car. -This was a 343 bored and stroked to 430 CID, supercharged, set up to burn alcohol and is said to have made 1000+ HP. -None of the vintage literature contains any statement about transmission failure (!) -IF there ever was a problem with the auto trans, surely the mainstream writers would have jumped on it and smeared the transmission, to blame something... -so typical. But no; did not happen. Some of the vintage literature clearly states that AMC desired Grant Industries to use the original AM Shift Command unit that came with the 343 engine for the racing effort. That means, the unit would have been an AM Warner Gear Model 11B unit. ------------------------------------------------------------------------------- What is the difference between AMWG M11B and AMWG M12? The only two differences I know of are: 1) The M12 uses one more friction plate to make both clutches contain five friction disks. 2) The M12 uses a 'two bolt front servo' to operate the front band vs. all other AM versions using a 'one bolt servo' for the same purpose. (the M11B is a 'four and five' unit, the M10B is a 'four and four' unit and they both have the 'one bolt front servo' -for comparison) (M10B unit was used behind sixties era Rambler 327 V8 aka 'Flash-O-Matic') So... essentially, the M12 is 'the hoss' of all AM Warner Gear iron case automatic transmissions. -It's the 'biggest-baddest' one of them all, made to cope with more torque in a heavier car than any other version (of the same basic unit) ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: Trader

Date Posted: Feb/06/2020 at 12:24pm

|

Many previous posts on this,by george w, "The "Shift kit" part number was 4488283." Lots of info on these previous posts if you search that number. |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 1:52pm

|

OK, good, I'll research that pn# -thank you. --------------------------------------------- As I understand it, I would like to explain a few general concepts that helps me to understand how automatic transmissions work. And, in theory, when we understand the basic operating principals, it takes some of the mystery out, and reduces 'fear of unknown' ...where knowledge of how they operate is considered to be a 'black art' -something 'magical' or 'too risky' for an average person to deal with. With exception of all electronically assisted 'new school' automatic transmissions, an automatic transmission like these (Ford-O-Matic, Cruise-O-Matic, FMX, Flash-O-Matic and Shift Command) is based upon 'hydraulic theory' where the unit is a system of hydraulic circuits. The hydraulic fluid in the circuits is like electricity flowing in an electrical system, where things turn on or off by fluid pressure acting upon springs and valves in the 'valve body' -which is like the switchboard of the unit. (where fluid pressure is like electrical voltage, pushing through the wires etc) Now the clutches and bands inside the automatic transmission are in analogy, similar to the brake system on our cars. -the 'friction plates', acting upon the 'steels' (inside the front and rear clutches) is like 'disc brakes' on a car with 'hydraulic brakes' -the 'bands' are like 'band brakes' on your go-kart when you were a little kid (but actuated with hydraulic fluid lines, not a metal actuation rod) ...so think of the frictions and bands like brake shoes; they have a 'friction lining' like the brake pads or brake shoes on your car. Now drive your car 'dragging the brakes'... someone who does this will wear out their brakes faster. More wear occurs when the brakes shoes are 'dragging' -making partial contact & 'slipping' the brakes instead of actually 'stopping the car'. IF one applies more pressure to the brake pedal, the brakes won't slip but they will 'grab' and stop the car (hopefully!) Same thing inside the transmission: more pressure and the frictions and bands 'grab' better instead of 'slipping' ...and/but when they slip a lot, they'll wear out sooner. ...Again, like the brakes on your car, if we stomp on the brake pedal, applying more pressure, it will make the car 'grab' to a 'harsh' stop. -as opposed to applying gentle foot pressure to bring the car to a 'comfortable' stop. -the gentle pressure though, depending on how 'gentle'... will indeed greatly affect the lifespan of the brake shoes (try not to 'drag the brakes' in your car, or you'll be paying to install new brake shoes sooner than later) Same thing, same analogy: If we apply more fluid pressure inside the auto trans, the frictions and bands will be more inclined to 'grab harshly' instead of a more 'gentle' shift 'feel'. ...Now the OEM designers of these automatic transmissions are always trying to eliminate the feel of 'hard shifts'... -the original goal was to make the car 'feel like it has a one speed transmission' -for that 'jet-thrust feel' -like a 'rocket car' or a 'jet car' (appealing to the higher technologies, for automotive higher tech charisma) So the automatic transmissions on our vintage AMC cars were set up to provide a smooth shifting feel -to imitate 'jet thrust power'... And this was the purpose of trying to use oversize/giant CID engines with two speed automatic transmissions; to create a 'jet like power' driving experience. (just stomp on the gas pedal and it 'takes off' in one seemingly smooth motion -like it has a jet engine in the car) Nowadays, one may be aware they are still trying to do this in those cars with CVT; 'continously variable transmission' -where the car has no shift 'feeling' whatsoever. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 2:28pm

|

So... this is part of the main purpose of installing a 'shift kit': to eliminate slip, which 'improves' the durability and generally makes the transmission feel more firm. But another part of installing 'race shift kit' is to 'raise the shift point' to a higher rpm (when the transmission 'decides' to shift gears automatically) On our vintage AMC Flash-O-Matic and Shift Command units, the max rpm shift point is around 4800 rpm. -It's made that way to work with the powerband of the stock engine(s). (where the stock engines are made to have an approximate 4000 rpm wide usable powerband; from about 800 to 4800 rpm) But when an engine is modified, like 'putting in a cam', many times the cam allows the engine to 'rev higher', but the transmission then, will shift too early. So the shift kit (depending on the kit) is also intended to 're-program' the shift points in order to work in harmony with the re-worked engine. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 3:11pm

|

Judging by my personal two fastest cars I've ever built using this same basic unit (one with M11B, and one with 10B) -you just 'hold it in gear' and the upper rpm shift point is of no consequence, where the engine is able to rev up as high as you want it to -no problem. XRV8 Gremlin (with M10B) is showing 'burnt fluid' though. It has 'paper' frictions. The burnt fluid is from slippage during a gear change. (I should install new fluid)

------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 3:41pm

|

I looked up that "Shift kit part number was 4488283" in the search window both ways and could not find anything. Anyway, just increase the 'line pressure' by adjusting the throttle control cable (M10B) or adjusting the vacuum modulator (M11B or M12) -doing this will decrease slip in the clutches (similar in analogy to applying more pressure to the brake pedal in your car -to force the brakes to 'grab', instead of 'slipping') I think I already said this before, but when one is rebuilding their Flash-O-Matic or Shift Command unit, notice how loose the bands are, when 'going by the book'. Look at 'em! Notice there's 'tons of space' between the bands and the drums they are made to grab onto. Now notice what happens if you 'adjust the bands 1/4 turn tight'... It's almost undetectable... easy to see there is no obvious-great risk to do so... What it does do though, is it reduces the time it takes for the band to grab onto the drum, since the band is 'set' a fraction 'closer' to the drum already. When we reduce the time, it reduces the amount of slippage required by the clutch to make a gear change. -the more time it takes to accomplish a gear change within the unit, the more slip occurs. -More slip = more 'smooth feeling' gear changes -Less slip = more 'firm feeling' gear changes. I always adjust my bands 1/4 turn tight and never see a worn band (I don't know what a worn band looks like ...I can imagine it/but never seen one) So with no shift kit available, that's why I say 'just increase line pressure by adjusting the cable or vaccum modulator & adjust your bands 1/4 turn tight'. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: scott

Date Posted: Feb/06/2020 at 4:01pm

| Thread on the "shift kit": http://theamcforum.com/forum/m12-shift-kit_topic58083.html" rel="nofollow - http://theamcforum.com/forum/m12-shift-kit_topic58083.html |

Posted By: Trader

Date Posted: Feb/06/2020 at 4:04pm

|

Also: http://theamcforum.com/forum/m12-performance_topic71054.html" rel="nofollow - http://theamcforum.com/forum/m12-performance_topic71054.html

|

Posted By: WesternRed

Date Posted: Feb/06/2020 at 4:13pm

Here is worn band for you amcenthusiast: ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Trader

Date Posted: Feb/06/2020 at 4:41pm

|

But Western, there are no heat marks or stress cracking showing. It' just plain worn out. Well done on maintenance and fluid changes!

|

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 5:17pm

|

Ok that's worn out for sure! This is what I'm trying to describe by using the analogy of brakes on the car: If one 'rides the brakes', this wears out the brake shoes. -the band is just like a band brake (it is a band brake) So this picture, as I understand it, tells me that band was slipping (excessive slip) This would happen if the servo was binding, or if the seal in the servo was not sealing properly, then it couldn't apply with enough force for the band to grab (and not slip) Those front servo seals are tricky to install. One needs 'three hands' to do it... Thanks for not cussing me out for posting such long boring essays. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 5:19pm

|

Ok here's a link to Alto's tech page telling about installing Red Eagle frictions in an AOD: https://www.altousa.com/downloads/tech-drawings/03-230-BM302.pdf" rel="nofollow - https://www.altousa.com/downloads/tech-drawings/03-230-BM302.pdf The AOD, re-used some of the 'ancient' original Ford-O-Matic parts sizes in the newer Ford reworked unit. Alto's Catalog pages here: https://www.altousa.com/images/uploads/Alto2011_website.pdf" rel="nofollow - https://www.altousa.com/images/uploads/Alto2011_website.pdf They all use the same size frictions and steels: See page 526 for BW12, see page 524 for Ford-O-Matic, see page 226 for FMX, see page 186 for AOD (page 264 for M35 aluminum case units -they sell Red Eagle frictions for those also, compare M35 to Ford C4...) Note: the AOD has another clutch added on to the design; this is a different sized clutch pack for the OD. Note: the earlier AODs came with cast iron clutch drums, the later units came with stamped steel clutch drums ~slightly different, as explained on the Alto tech page. Around '72, the FMX units began to come with 1/2 as many 'teeth' inside the clutch drums. This way, Ford workers would only have to do half the work to make the same part = machine half as many teeth = double production speed and make twice as many. (GM clutches were already done this way since the new for '65 TH400 -made with half as many 'teeth' in the clutch drums -obviously easier to make when one understands the manufacturing aspect) So all the post '72 FMX clutch drums will look different from the earlier '67-'71 clutch drums, because they cut half as many teeth inside the drum. Those affect the 'steels', how they interface with the clutch drum... but the later type steels will still fit into an earlier drum. The inside teeth, on the friction discs, did not change -the teeth that interface with the 'cog' which connects to the splines on the 'intermediate shaft'. -So basically all the frictions and steels should interchange, but only the FMX and AOD steels made with half the teeth can fit into those later units. (hope I said that right) I plan to try this idea when I'm able. On the same tech page, Alto lists their 'select fit' clutch snap rings. They state to set up the clutch drums with .030" clearance/space. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 5:30pm

|

The FMX Red Eagle frictions and Kolene steels are on page 226 of Alto catalog. These should swap into BW12, BW11B & BW10B. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/06/2020 at 6:08pm

|

Ok thanks for posting the links for me to read what's been said about 'shift kit for M12'. Funny thing is, the quoted information says 'the valve body provides increased pressure'... (not word for word) However, it can't. Only the pump can do that -just a minor technical issue... I've done enough research to know for sure that by adjusting the throttle control cable on 10B, or vacuum modulator on 11B or 12, this does have a direct effect on line pressure to all circuits. In other words -the adjustment raises or lowers the pressure from the pump to all circuits in the valve body. (this is somewhat stated in the quote but not exactly clear) When the pump is making more pressure than needed, it has a dump valve that dumps excess pressure back into the pan (like if one were to shim the pump pressure spring with a penny etc) -This way, when the pump is making more pressure by means of the engine spinning faster, the pressure is regulated by the dump valve anyway so the valves, springs and plungers in the valve body still work the way they're supposed to regardless of what rpm the engine is turning. (this was one of the minor changes Ford made to FMX; they changed the orientation of the dump valve slightly, on the pump) Where 'plumbing' is an analogy for 'electricity', the dump valve is like the 'cut out switch' on an old school voltage regulator. Sure, it's tricky to 'say it right' what-does-what. In analogy, the throttle or modulator valve is like 'an adjustable doorway' from the pump, to the valvebody. (within the designed range of pressures; it only does so much) Where plumbing is an analogy for electricity, the modulator valve is like the voltage regulator on the back of the instrument cluster. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: rsrguy3

Date Posted: Feb/06/2020 at 6:09pm

|

This is the guy that will be building the m12, I have high hopes for a durable mildly upgraded trans. We'll see fingers crossed.

Gary is in the far lane. https://youtu.be/r2wtBPYs3eE" rel="nofollow - https://youtu.be/r2wtBPYs3eE

------------- javguy |

Posted By: WesternRed

Date Posted: Feb/07/2020 at 12:01am

|

Amcenthusiast, I can see where you are coming from with your last post but from my interpretation of how it works. The dump valve you refer to is the main or line pressure regulator on the valve body, so that limits the maximum pressure to say 300 psi. The vacuum modulator to my understanding reduces the pressure to the servo pistons and/or clutch packs when changing gears to make the shifts smoother. One of the problems I see with the BW transmissions is that there is not enough information in the TSM to properly diagnose and adjust things. You should be able to measure the oil pressures at different parts of the transmission and under different conditions, there are even ports to do this, but the TSM doesn't provide any specifications other than pressures for adjusting the vacuum modulator. This is where information on possible performance upgrades is also lacking. We need something that says to shim the main pressure relief valve to increase line pressure from say 300 to 350 psi. Like anything, I assume there will be negative consequences if you go too far. As for the drum and band picture I posted, the transmission had done no more than 5,000 miles, probably a lot less, since the previous rebuild. The band was actually distorted, so there was excessive heat there and the oil was black as the proverbial ace of spades. The transmission did work fine up until the band wore out, as always, I knew it was on the way out, but didn't get around to doing something about it soon enough and did more damage than necessary. Bands were adjusted and fluid changed within that time, but again probably too late and the damage was already done. I don't want to mention type-f fluid, because that is another whole can of worms. The rear drum frictions and steels were also burnt up. If you read that old magazine article about the B & M upgrades, they mentioned that they could only get a handful of passes out of the standard transmission before it needed to be serviced, I probably got about 75 out of mine. I have rebuilt it again now and do not plan on racing it this time around, most likely will last a little longer. I have a 727 in another car to do the racing with now and can have things like a full manual reverse pattern valve body, bolt in sprag, billet servo pistons, off the shelf high stall converter and lots of other goodies when I need them. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: farna

Date Posted: Feb/07/2020 at 6:59am

|

Better clutches/bands and reprogramming by shimming the accumulators (and main pressure if you want) is how the AW4 is beefed up also. It's pretty much a modern version of the M-12... as is the BW65 used in many European cars. ------------- Frank Swygert |

Posted By: amx007

Date Posted: Feb/07/2020 at 8:27am

|

Great info a book in writing this is so cool a gear head trans guy should know this hope to see a small book out there nice job my guy in stone Pk is a great builder Gary ------------- dream red white and blue 1968 Chicago auto show amx 290 4 speed 1969 driver Amx 290 auto |

Posted By: amcenthusiast

Date Posted: Feb/07/2020 at 8:33am

|

Frank, I believe you are a good natured, kind hearted man. In this thread we're trying to get away from the myths and get down to brass tacks on hopping up this trans that came in our favorite cars.The BW65 unit uses some BW35 internal parts, indicating it's evolutionary trace. This transmission offers no potential performance improvement for our vintage American Motors cars. It's more like a Ford C4, having it's band servos integral to the case (where one might say it looks like 'BW copied Ford a little bit') This transmission by the way, tends to de-elevate 'the Jaguar mystique' because IMO it is not robust or technologically superior in any way: it's just another light duty two band non-overdrive three speed automatic -without a cast iron case. Perhaps slightly more robust than Ford C4, I would rank this unit alongside early seventies GM TH250. It's all metric, like some versions of BW35. The late-eighties Asin-Warner aka 'AW4' is a totally different all metric design. It's not an obvious evolution of the M8-12 series either. It is a 'thoroughly modern' electrically assisted unit that has no bands -all bands are replaced with large diameter disc type friction clutches instead, contrasted by ancient 1949 DG-200/250 design which is a three band two clutch unit. A discussion of these units does serve the purpose of comparison, to help place the AM iron case units higher upon the scale of torque handling capacity; none of those units has the glorious heritage of having been used in a class winning supercharged alcohol Funny Car drag race category, where all those late-sixties AMC cars have 1000+ hp Grant Rebel SST for their super-hero role model. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/07/2020 at 9:01am

|

Back to the original question where Red asks: "Ok, i know everyone is going to say just upgrade to the torqueflyte or turbo 400, but what really is wrong with the M12 as a mild/moderate performance trans? I know parts for it are hard to come by, particularly any sort of performance upgrades but if you can get the Ford FMX to handle 500+ HP why can't the M12 do the same given their shared heritage? Surely for a mild performance street/strip engine, mine is closer to 350HP, the M12 or maybe even the M11 should be more than adequate and avoid the additional work and expense of swapping over to one of the other two." ----------------------------------------------------------------------------------------- 'Drop in' higher performance parts for our American Motors iron case automatics*: Alto Red Eagle Frictions pn# 049740 or 049740UP5 (unit pack, 5 discs) front clutch, .060" thickness Alto Red Eagle Frictions pn# 049742 or 049742UP5 (unit pack, 5 discs) rear clutch, .080" thickness Alto Kolene Steels pn# 023701K or 023701KUP4 (unit pack, 4 plates) both clutches, .068" thickness *should be 'drop in', but I have not done this myself. These are listed in Alto's online catalog, for Ford FMX on p.267 (current, as we speak) Notice in the catalog, the specifications are identical for BW8-12 frictions and steels listed on p. 526 (where the FMX traces it's evolution to BW8-12) ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/07/2020 at 9:11am

|

One of the reasons not to avoid using the Shift Command units is that they feature a low parasitic loss number, same as FMX. Where the more popular choices such as 727 or TH400 chop about 10 hp off power going to rear axle. The difference is, as I see it, related to the diameter of the internal rotating parts, where the 727 and TH400 have larger diameter clutch drums and planetary units, the drain slightly more energy from the engine to make them spin. In other words, the AM iron case units offer lower parasitic drag, for a performance benefit/increased power to the rear axle. ------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: amcenthusiast

Date Posted: Feb/07/2020 at 9:38am

|

Yes, I had to research the assertion that 'adjusting the modulator' or 'adjusting the throttle control cable' does indeed adjust total line pressure to the valve body -so I'm not a liar. It does; the vacuum modulator is simply a different actuation mechanism than the throttle cable on some earlier models (like '65 M10B) Both do the same thing; they both manipulate a particular valve which is like 'a door' leading to all the other valves in the valve body, to raise or lower all pressure from the pump which is delivered to the valve body as a unit. By adjusting the setting higher, it's like pressing on the brake pedal harder to make the brakes grab more firmly. By adjusting the setting lower, it's like pressing on the brakes 'lighter' to make a 'gentle' stop, slipping the brakes instead (the more slip, the more 'smooth' the transmission 'feels') Same thing with the brakes on a car: If the person tends to 'ride the brakes' (slipping the brakes while coasting etc) the brakes can overheat and the shoes will wear out much faster. So when we see worn friction linings on the bands and friction discs inside the transmission, this tells us there was excessive slip happening in the unit. Sometimes excessive slip can happen when a sealing ring, or an o-ring is somewhat defective, to allow a fluid leak in that particular hydraulic circuit. Typical, when we see something like the fried band in Red's unit, this means basically all the 'soft parts' in the unit are damaged by excessive heat and should be replaced -all O-rings and shaft seals are most likely become 'hard' from overheating. Don't let 'em run low on fluid. Don't overfill; this causes fluid aeration (not good for cooling or lubrication)

------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: WesternRed

Date Posted: Feb/07/2020 at 5:18pm

|

Maybe we need to look at the Jaguar TSM for these transmissions for some more ideas, one of the problems with the AMC TSM is that the BW11-12 has 4 ports on the rear of the transmission for different oil circuits, but the TSM only references one as per the earlier transmissions. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: WesternRed

Date Posted: Feb/07/2020 at 6:32pm

|