Advice on cam choice - is it too big - AMC 401

Printed From: TheAMCForum.com

Category: The Garage

Forum Name: AMC V8 Engine Repair and Modifications

Forum Description: AMC-made V8 engine mechanical, ignition and fuel from basic repair to high-perf modifications

URL: https://theamcforum.com/forum/forum_posts.asp?TID=103579

Printed Date: Apr/18/2024 at 9:26pm

Software Version: Web Wiz Forums 12.03 - http://www.webwizforums.com

Topic: Advice on cam choice - is it too big - AMC 401

Posted By: Halvard

Subject: Advice on cam choice - is it too big - AMC 401

Date Posted: Jan/13/2020 at 12:58pm

|

Ok, so I am looking for some expert advise outside Comp Cams

sales department, where I was a bit disappointed with the advice I got. I had a friend build me a 401 a few years back. It is a

solid and strong piece, but I think I made a mistake on the only part of the

build where I got to choose between a few options: the cam… I was recommended to

go bigger, but I chickened out and went for the smallest Extreme Energy cam (CL10-214-5)

to make sure I had enough torque to go off-roading. In retrospect, I think I just

should have chosen a cam that idles somewhat OK, and is not too choppy. In case

there are any offroaders in here, the Jeep is well built when it comes to

crawling, and has a crawl ratio of 107. It will go up steep hurdles and

boulders at idle not using any pedals (which is the reason I want to maintain

somewhat of a decent idle). At this point, Comp Cams suggested I should go for

a hydraulic flat tappet Mutha Thumpr, even though I had explained the crawling

part and that I was looking for a roller option… Some details: Jeep CJ 7 with a SM465 manual transmission, axle ratio of

4.11 and running on 35” tires. It weighs in at roughly 3200 lbs. The engine has an

Edelbrock Performer RPM intake, ported Edelbrock Performer heads and a CR of

10.1:1. Roller rockers with ratio 1.6: 1. Dough Thorley headers, Fitech EFI and

running on 98 octane pump gas. It has hydraboost brakes and power steering. Nothing

runs on vacuum. The engine is ridiculous strong from low RPM, and it almost

lifts one wheel of the line. I have had problems with pinging under heavy load at low RPM.

I tried to retard timing, but was not able to get rid of it until I went from

95 to 98 octane fuel. Could this be because of the small cam compared to the

rest of the build? The other reason for changing cam is street racing. The Jeep

is not the perfect candidate for this, but it is great fun smoking street cars

in this thing. Here is where I feel I run out of engine too fast and would like

to extend the RPM range beyond 5500. The SM465 has 4 gears, but 1st

is granny low, so only 2, 3 and 4 is used. The power band I am looking for is kind of dictated by

3rd gear. Keeping second gear to about 6500 RPM makes me shift at 46

mph, entering 3rd at about 2600 RPM. When I reach 6200 RPM in 3rd

I am doing 100 mph, and nobody needs to go faster than that in an old jeep… Highway

cruising is between 2500 and 2700 RPM. So… Here’s my question(s): How much cam is to much cam for my application, in as where is the limit for reasonable idle quality? This is the cam I am looking at: XE291HR-10 http://www.compcams.com/xtreme-energy-236-242-hydraulic-roller-cam-for-amc-290-401. - https://www.compcams.com/xtreme-energy-236-242-hydraulic-roller-cam-for-amc-290-401.html Will it feel strong from 2000 RPM, or will I need to go smaller to get that low end grunt? I have been thinking that as long as I stay within the

Extreme Energy family of cams, the 401 will handle it... 401s likes big cams?

Right? Expert opinions welcome |

Replies:

Posted By: Trader

Date Posted: Jan/13/2020 at 1:24pm

|

I believe your looking at the wrong end of the spectrum. A cam will give you low end torque or high end torque but cannot give you both. Everything is a compromise. If stuck on Comp, have a look at Summit, the 10-201-4 or 10-214-5. Look at the RPM range of both, starting at about 1,200. With either of these you will be well into your RPM (off idle) for torque. The last thing you need on a grunt machine is to be out of your RPM range when you need the torque. My opinion.

|

Posted By: Halvard

Date Posted: Jan/13/2020 at 1:42pm

|

I understand best of both worlds is not possible to achieve. I tried to write the post in a way where I try to explain I would like retain a decent low end and add more up top, which I still think should be possible. Your suggestion is to stick with the cam I already have or go even smaller... |

Posted By: Trader

Date Posted: Jan/13/2020 at 2:01pm

|

Basically yes, unless you want to burn up clutches. Once you get over 1,500 RPM to develop torque on a manual transmission Jeep, you will have to start riding the clutch. If you had an automatic, then you could adjust your converter and cam RPM range more. But at the end of the day, you still cannot have a rock climbing drag truck unless you add many more transmission gears. |

Posted By: mixed up

Date Posted: Jan/13/2020 at 11:13pm

|

my opinion is he muther thumper is a sound good cam what I mean by that is desige to sound good for cruising with no practical use m suggestion is go online look at many cam look at the power range and choose from there look at Howard cam they have some nice specs crane cam summit cam with out looking at the spec you have now I think you would be good with like a 530 lift 280 duration but I found amc engine like a split ratio duration for good power and Its a Manuel you don't have to worry about a lumpy idle ------------- 69 amx 290 auto 65 220 290 4spd 80 ford fairmont |

Posted By: Halvard

Date Posted: Jan/14/2020 at 12:43am

|

Thank you guys, but that was two answers at complete opposite sides of the spectrum. Maybe I didn't make myself clear in my original post: I am looking for opionions on how Comp Cams XE291HR-10 will behave in my engine, with the specs I have listed. For offroad used the Jeep is built and geared in a way that I could crawl it with a Suzuki 4-banger (1st gear @6.55:1, transfer case rebuild to 4:1, axles 4.11:1). I just need it to idle decent... As a street application, it will be off the line in 2nd gear@3.58:1 (pretty normal stuff) and burning clutches has never been an issue. So again, I would be really thankful to get some input on how you other guys think the XE291HR-10 would make my engine behave. Thanks

|

Posted By: PROSTOCKTOM

Date Posted: Jan/14/2020 at 1:48am

|

In my opinion a roller cam by design of the lobes give you a lot more performance over a flat tappet even at the same duration. I read somewhere that a roller cam even though the same duration the roller will act like it has 15 degrees more cam in it than the flat tappet. So 236/242 would be a little more than I would suggest if you want it all. A 230/236 roller would probably do you better. You already have good flowing heads, so you don't need to much cam to make it really work well. That's my 2 cents. For comparison I have a 440 Mopar with a Comp Cams Extreme Energy with 236/242 .585" lift in it and it really doesn't come on hard until 2500 rpms. Tom

------------- Molnar Technologies Full Service Dealer - Crankshafts & Connecting Rods 1969 AMC Rambler Rouge Race Car 1974 AMC Hornet Hatchback, Wally Booth Outlaw Nostalgic Pro Stock Race Car Project |

Posted By: Halvard

Date Posted: Jan/14/2020 at 2:13am

|

Thanks for the input Tom. I agree with what you say, and have also been thinking about flat tappet vs roller (even though the XE flat tappet is very aggresive on the ramps) and 230/236. My problem is that I am starting to know the Extreme Energy range, and I'm a bit afraid to try something else and fail. I have seen a very similar engine to mine run with the Extreme Energy roller 212/218. It is both a torque monster and racier than my engine, but I know it would also happily take more cam. The problem with the Extreme Energy series (3 versions) is the big leap between them. Looks more like two sizes up per step to me... The medium of the three has only 224/230 duration, and this is why I am trying to figure out if I can get away with the largest in the series. ¨ Edit: I have gone a few rounds with myself and found out that I don't need to make power above 6000 RPM. This makes the tourqe curve on the 224/230 very appealling vs the higher RPM on the 236/242. I keep looking at the curves, but can't really understand where/when the benefit of the bigger cam kicks in. https://www.compcams.com/xr276hr - https://www.compcams.com/xr276hr https://www.compcams.com/xr288hr - https://www.compcams.com/xr288hr

|

Posted By: mbwicz

Date Posted: Jan/14/2020 at 5:28am

|

There are several companies that will do custom cams as well, unless you need something quickly or off the shelf. Its an interesting situation that you have. GrayhoundAMX has a cam chart that helps with the dynamic compression ratio, which is important. The existing small cam that you have will likely have very high DCR, which could explain the pinging that you have at low RPM now. You are doing the right thing asking for peoples opinion here. As a side note, I was able to improve the idle on my Pontiac (455, 236/245 HR, aluminum heads) by switching to iridium plugs. Some of the lumpiness with the idle comes from misfires, and the fine-wire plugs eliminated some of them. Just switching plugs I picked up over 300 rpm at idle with no other changes. Just my experience, others may disagree. Have fun! ------------- 1970 AMX, one step forward, one step back. Both steps cost time and money. |

Posted By: Buzzman72

Date Posted: Jan/14/2020 at 5:56am

|

Crane roller cam 869501. Grind # HR-208/3313-2S-12.RPM range 1000-5200. Lift .530, advertised duration 264/272. Should put you right where you want to be. See forum discussions on which hydraulic roller tappets to use. ------------- Buzzman72...void where prohibited, your mileage may vary, objects in mirror may be closer than they appear, and alcohol may intensify any side effects. |

Posted By: Steve_P

Date Posted: Jan/14/2020 at 6:57am

|

The problem with 240*+ duration cams is that 230* duration cams generally make more power up until 5000 RPM. And you are going to be spending a lot more time below 5000 RPM than above it. For me ~230* the limit unless you are building an engine only for track duty. And despite what excel spreadsheets tell you, don't expect miracles with a bigger cam stopping pinging. I've added 30 degrees duration and not seen any real difference in tendency to detonate. With 55 year old combustion chamber design, 9.5:1 is a reasonable limit. |

Posted By: Shawn_Watson

Date Posted: Jan/14/2020 at 4:29pm

|

In my opinion, you're looking for a custom somewhere around 228*/235* at .050 on a 106 LSA. You'll probably break drivetrain parts though :) Edit: Basically no one you talk to will agree but you'll be sold once you try it.

|

Posted By: WesternRed

Date Posted: Jan/14/2020 at 7:42pm

|

The XE276HR-10 looks like it is leaving a fair bit on the table in the lift department as far as hydraulic rollers go. 276/282 adv dur, 224/230 @0.050" dur, 0.513"/0.513" lift It almost looks like it is intended to work within the lift limits of the stock iron heads. For comparison Crane HR 224/239-2S-12 286/294 adv dur, 224/232 @0.050" dur, 0.542"/0.563" lift Will give you a bit more lift but for similar 0.050" duration but does add a bit of total duration as well (maybe not what you want). With ported Edelbrock heads, you should be able to support a fair bit of lift, 0.580" is the stated limit out of the box. I'd be looking to make the most of that lift potential. You can either get someone like Bullet to do a custom grind for you or if you go with the Comp roller, I'd be looking at running 1.7 rocker ratio as well to add a bit more lift. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Halvard

Date Posted: Jan/15/2020 at 12:04am

|

mbwicz: Thank you for your input. I am also hoping Greyhounds_AMX will have the time to give his thoughts on the matter

WesternRed: Do you know where I can find more data on the Crane HR 224/239-S2-12? It looks interesting, but I can't find much data on it. I have little experience on how lift affects the power curve vs duration, but I'll look into it. Rocker arms will most likely stay at 1.6 though. Thanks for the input. |

Posted By: WesternRed

Date Posted: Jan/15/2020 at 1:36am

|

Both Comp and Crane seem to have updated their websites and the new ones are rubbish. The cam is still listed in the Crane catalogue, so that is probably the best place to start. Engine output is largely a function of how much air (and fuel) you can get in. With a normally aspirated engine, that is basically controlled by the cam and head flow, there are of course many other factors involved. With the cam, increasing the cam duration gives the air more time to enter the cylinder, so you can potentially make more power, but it tends to be at higher RPM and you trade off torque lower down in the rev range. More lift also allows you to get more air in provided the rest of the induction system can support the extra flow and you don’t trade off low end torque. Sounds maybe too good to be true, but usually you are also limited by the capability of the valve train as to how fast you can open and close the valves as well as various clearance limitations. The Comp Extreme Energy (XE) series is a good example of this thinking however as I think you have already noted, they are regarded as being harder on the valve train. The big attraction of hydraulic rollers is that they also allow for faster opening and closing of the valves so you can gain horsepower without sacrificing torque. You will hear people talking about area under the curve and this is what they are referring to. In your case I’d be looking at the Comp XE 274 if you want to stick with a hydraulic flat tappet.

------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Halvard

Date Posted: Jan/15/2020 at 1:46am

|

Thanks again WesternRed. The goal is definitely to move over to a roller cam. |

Posted By: PROSTOCKTOM

Date Posted: Jan/15/2020 at 5:26am

|

I would tend to stay on a much smaller side of cam than some your looking at. For comparison my 94 Ford F150 Lighting with a 351 5.8L came factory with a hydraulic roller cam that had 196/208 .413"/442" lift on 114 degrees. It pulled extremely well for an engine that was only rated at 240 HP @ 4200 rpms, 340 lb/ ft torque @ 3200 rpms, and the truck weighed 3886. The point is if you want it really crisp don't over cam it. Could that engine have used more cam? Yes in my opinion it could have used 20 more degrees. So with that said, it would have been 216/ 228. However you have far better flowing cylinder heads, so again there is really no need to get carried away with the cam and you already have the ability to open the valves a lot further with those heads. Something with a 224/ 230 with .575" lift on 112 lobe separation would be a great cam. Odds are you'll need to order a custom grind to get exactly what your after and Bullet Cams has seemed to be the place for the AMC guys to go to in the last several years. Tom ------------- Molnar Technologies Full Service Dealer - Crankshafts & Connecting Rods 1969 AMC Rambler Rouge Race Car 1974 AMC Hornet Hatchback, Wally Booth Outlaw Nostalgic Pro Stock Race Car Project |

Posted By: Halvard

Date Posted: Jan/15/2020 at 6:13am

|

Thanks Tom I am starting to fall in line with the smaller duration and bigger lift. The cam that WesternRed refers to is not too far of what you are talking about, and I think that would be the basis for discussing something custom with Crane or Bullet. Crane HR 224/239-2S-12 286/294 adv dur, 224/232 @0.050" dur, 0.542"/0.563" lift on 112 lobe separation. How would 110 lobe seperation (which I seem to find on most of the cams of this type) change the characterisitics? Anyone have any direct contacts that are good with AMC at either Crane or Bullet? |

Posted By: WesternRed

Date Posted: Jan/15/2020 at 9:13am

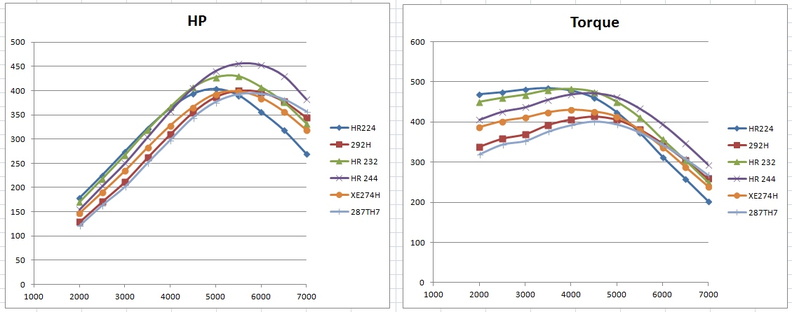

Here is a bit of a simulation of some of the Comp cams using Dyno 2000, from memory, the engine would have been based on my AMC V8, so 375 cubes, 10.5:1 compression, Eddy heads, dual plane intake and small tube headers. For reference, I do run the Crane HR224 in this engine, which is in my Javelin, real world horsepower is probably closer to 350 and peaks around 5200 RPM.

------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: i6cj7

Date Posted: Jan/15/2020 at 10:26pm

|

To the OP, first off, your CJ7 sounds awesome. Mine is VERY similar. And i think maybe some guys here aren't familiar with the Sm465, and how light a CJ7 is.. I have the original 4.2 inline 6 in mine, Sm465, 33" Mtz's and 3.54s in the axles. There is no shortage of torque with the 4.2 and that 6.58 granny first gear. With your 35s and 4.11 gears.. You have PLENTY of gearing.. I was only going to do 3.73s with 35s to keep the revs down on the highway with no overdrive. That 401 probably has two and a half times the torque of this old worn out 258, youd have no problem gettin a cam with some bump to it. 270ish or bigger would be fine. My crawl ratio is 70-1 and in first and low range 2wd, if I stand on the brakes with no gas pedal it won't stall.. The front brakes lock, and the rear tires will keep spinning and dig a hole.

A bigger cam would keep it from pinging, and I'm betting would give you better gas mileage on the highway. Since with 4.11s and 35s you're probably turning what? 3k rpm doing 60 to 65mph? The Sm465's wiiiiiide gear range let's you have crawling ability (which you already know) in first with a choppy cam, and then with the power and torque of the 401.. Yeah you'll be happier with something that let's that beast breathe.

|

Posted By: Halvard

Date Posted: Jan/16/2020 at 12:32am

|

Thank you for the time spent on those graphs WesternRed. The HR224 is definately looking strong, but I wonder if the HR232 is in fact looking even better... It is at least making me think that it is worth making a call to discuss custom grinds, to tweek the cam to fit my application... i6cj7: Good to meet a fellow jeeper on here. Sounds like a solid setup you have there. I hear your points, and I agree with most of them. First of all, I love the SM465 both for the extremely low first gear and the fact that it just feels unbreakable. But it is also the achilles heel as a street application. The few and wide gears makes it hard to downshift in to some appropriate RPM range when you need it. I am also questioning how happy it will be shifting from 2nd to 3rd at 6500 RPM the way it is built (twice as big and heavy as my original T-176). That gear shift would be the only time this engine will rev past 6000 RPM... If I still had the T-176, with a normal 2nd and 3rd gear, the desired RPM range would probably look a bit different. My cruising RPMs in 4th gear (50-70 ish MPH) will range from 2000-2800. I would like the cam to perform well in that area and up to 6000 for some highway shenanigans without having to drop down a gear. In any ways I will reach my pucker factor top speed of 100 MPH at 6000 RPM in 3rd and 4000 RPM in 4th, so no need to shoot for cams with duration moving the curves too far to the right. |

Posted By: WesternRed

Date Posted: Jan/16/2020 at 2:52am

|

The HR232 doesn't appear to give up much on paper, plus you do have a few extra cubes to help things along, so maybe bigger is better in this instance. On the flip side, your heads are ported, so you should be able to do more with less cam. The charts are just something I had laying around from some previous investigation, otherwise it would have been good to plug in a couple of the smaller cams for comparison. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Halvard

Date Posted: Jan/16/2020 at 3:54am

|

Thought I'd show (off) what I'm working with copy+paste links into browser. https://drive.google.com/open?id=11jmCSFtNE85UjaKkyLCHPv_ipf-76Tbh Launch in second and shifting to third. Doing about 60 when passing the camera man https://drive.google.com/open?id=11wNtJrdm6xr1NbxkuqE20DF-A-bjYcQ_ Crawled that hill and those boulders without using any pedals. EFI working great and idle set to 750. |

Posted By: i6cj7

Date Posted: Jan/16/2020 at 10:45am

|

Sounds like you drive like i do.. Maniac.. You need a sequential 6 speed.. Lol, I'd like one too but $20k ain't in the budget right now.

That 2nd to 3rd upshift is a loooong throw in the SM, [and the gear change 3.58 to 1.70] is a big drop as well... Having a broad torque range will help keep the engine in its power band for that shift. I'm not even sure the SM synchros will like shifting at 6500rpm.. Its a truck trans, not a race trans unfortunately. Look into redline synthetic oils for a lighter/slicker gear lube. I've been meaning to change mine. And change it every few years. Mine shifts and goes into gear alot nicer with fresh fluid. As for downshifting, I've started rev matchin, heel/toe downshifting. It's easier on the synchros, and actually goes into gear with less effort. As you're going from 3rd to 2nd especially, clutch in, toes on the brakes, and blip the Throttle with your heel. Man.. That's a beast of a CJ, great video! Where do you live? I'm out in Virginia

|

Posted By: WesternRed

Date Posted: Jan/17/2020 at 1:42am

|

I'm sure somebody on here posted some dyno figures for a roller cam engine around the 224 duration mark, possibly jcisworthy, but I can't find the thread. I see the XE291HR-10 was the cam used in the car craft 440 AMC build, so I gather you have read that article. Would be worth comparing the dyno numbers and build specs for the two. Also thinking that as some point your performer intake might be a limitation at higher RPM and that the airgap might be a better choice. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Trader

Date Posted: Jan/17/2020 at 7:47am

|

Your definitely out for the extreme. Have you thought of adding one of these: http://www.torqstorm.com/kits_single_AMC.html" rel="nofollow - http://www.torqstorm.com/kits_single_AMC.html That or a little nitro's will give you the tire squealing boost at the upper end. I,ve seen a electric clutch/ intake "gate" added to these that's cool. Supercharger is switched on when wanted - otherwise know one knows.

|

Posted By: Halvard

Date Posted: Jan/17/2020 at 2:30pm

|

So I emailed both Crane and Bullet, and Bullet was the first to come back with a cam suggestion. The say: .520/.520 lift 296/301

adv 238/242 @.050 111 C/L + 4 adv Rpm 2000 to 6000 I would have thought more lift, less duration and 112 LSA. Wrote that back to them and waiting on a response. Right now I think the off the shelf cams from Crane are looking

better, even though I don’t understand why they have narrowed the LSA on the

232 cam… Also, my heads are advertised good for .580 lift. Will .584 fit? HR-224/339- 2S-12 .542 .563 286 294 224 232 112 HR-232/352- 2S-10 .563 .584 294 302 232 240 110 WesternRed: I found something about a 208 cam at work, but lost it again. A 343 with lots of torque. Was that the one? i6cj7: Thanks. It is definitely getting there :) I bought my SM from Novak Adapters, and it has been flawless. I have not experienced any of the shifting issues I have read about from the states. Don't see them much over here as we don't get as many full size trucks as you do. I from Norway, so quite a way aways ;) Trader: I have seen that thing. But I am pretty sure I am stretching the limits of u-joints, general drivetrain and what not as it is already... |

Posted By: PROSTOCKTOM

Date Posted: Jan/17/2020 at 4:26pm

|

After looking at Darren's (WesternRed) dyno chart I would have to go with the HR232. If you were only rock crawling I would go with the HR224, but since you want the best of both World's it has to be the HR232. Plus it's a stocked shelf grind and easily available. Buy one and let us know the results. Tom

------------- Molnar Technologies Full Service Dealer - Crankshafts & Connecting Rods 1969 AMC Rambler Rouge Race Car 1974 AMC Hornet Hatchback, Wally Booth Outlaw Nostalgic Pro Stock Race Car Project |

Posted By: Halvard

Date Posted: Jan/17/2020 at 4:30pm

|

How about the lift?

Is it room to pass the advertised limit by .004?

|

Posted By: WesternRed

Date Posted: Jan/17/2020 at 6:03pm

|

I think you will be fine with the lift limit as far as the heads go, but you will need to check piston to valve clearance. That can be one of the reasons LSA is reduced in the bigger cams. Do take on board that the comparison chart I posted is just a simulation, so actual results may vary. Though in hindsight I do wish I had chosen the 232 over the 224. My engine makes peak HP at about 5300 rpm, but in a car application that is heavier than the Jeep, never had an issue down low with 2.87 gears and stock stall other than tearing up the transmission twice. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: WesternRed

Date Posted: Jan/17/2020 at 6:06pm

|

PS: would be good to see the full lift profile of the different cams duration @ 0.050” and total lift really isn’t enough information to make a proper comparison. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Greyhounds_AMX

Date Posted: Jan/22/2020 at 12:28pm

|

Almost everything I've focused on has been hydraulic flat tappet, as those are what most folks use in their builds. Also most folks tend to pick an off the shelf grind, so I've honed in on methods to help us pick something that's going to work well. With your build the Comp XE256H you have is closing the intake too early to allow 93 octane pump gas. The DCR works out to 8.65, and the typical limit for an aluminum head engine should be closer to 8.15. So the pinging seems consistent with what I'd expect with that cam. That's why I made the spreadsheet, to bring that issue to your attention so you wouldn't have picked that cam to start with if you wanted to run on 93 octane. With the Edelbrock aluminum heads and assuming a tight quench clearance there's no reason you shouldn't be able to run 10.1:1 compression. It's at the absolute top end of the typical limit, so you might expect to have to pull out a little timing. As far as a replacement cam that would get you a little more RPM, if you were willing to stick with flat tapped hydraulic cams I'd look at the Lunati VooDoo 10100702. It would shift your DCR down to 8.11, so 93 octane should be workable. And it moves the overlap factor up from the 1.04 of the Comp XE256H up to 1.24, and that increase in overlap will push the working RPM range up just a tad. You will definitely loose a little bottom end to gain that top end. The other advantage of the VooDoo 702 is that it's a 0.904 lifter grind design, and gives about 10% more overall intake flow than the Comp you currently have. That should translate to approximately 10% more power.  But if you want to go with a roller cam I'm not much help at this point in time. ------------- 1968 AMX 390 w/T5 |

Posted By: PROSTOCKTOM

Date Posted: Jan/22/2020 at 5:04pm

Tom ------------- Molnar Technologies Full Service Dealer - Crankshafts & Connecting Rods 1969 AMC Rambler Rouge Race Car 1974 AMC Hornet Hatchback, Wally Booth Outlaw Nostalgic Pro Stock Race Car Project |

Posted By: Heavy 488

Date Posted: Jan/22/2020 at 5:12pm

|

Octane isn't globally the same. I believe Their 98 is still close to our 93. |

Posted By: Trader

Date Posted: Jan/22/2020 at 5:45pm

|

Heavy 488 is correct, Europe uses RON (Research Octane Number) and US uses PON (Pump Octane Number) which is averaged between RON and MON (Motor Octane Number). So 98 there is 93 here EXCEPT if they have added ethanol to boost the octane number. Ethanol above 15% throws a wrench into the whole octane rating system. So regardless of cam chosen, if it pings, move to higher octane or no ethanol. Should add, Mobil/Exxon 93 is 30% ethanol. If your car runs fine with it, then go for it, except it will corrode older carburetors and fuel lines, just be warned! |

Posted By: Sonic Silver

Date Posted: Jan/22/2020 at 7:37pm

http://www.exxon.com/en/ethanol" rel="nofollow - www.exxon.com/en/ethanol |

Posted By: WesternRed

Date Posted: Jan/22/2020 at 9:00pm

|

Not sure about Europe, but in Australia that means that it "may" contain up to 10% ethanol, meaning it may not contain any if they can't get it. We also use the European style RON rating. ------------- I've finally given up drinking for good...........now I only drink for evil. |

Posted By: Heavy 488

Date Posted: Jan/22/2020 at 9:44pm

|

Premium fuel across the US varies by longitude/elevation. I believe the east coast has a 94 octane up to approaching the great lakes where 93 takes over up to the Mississippi River. From there, west goes down to 91. Non alcohol gas has 2 options. 100 octane unleaded race fuel at a few stations, or non alcohol 91 "RV" gas which is a good distance from major metropolitan areas off the interstate. |

Posted By: Sonic Silver

Date Posted: Jan/22/2020 at 9:53pm

|

Posted By: Heavy 488

Date Posted: Jan/22/2020 at 9:59pm

|

Ours is 87,89,93. When I cross the Mississippi headed west, all I've seen is 85,87 and 91

|

Posted By: Trader

Date Posted: Jan/22/2020 at 10:44pm

|

We could go on to a whole other thread that would single out regions of North America were the "same" product is not the "same". There is summer and winter gas in the northern US and Canada. Mobil 94 in Ontario is 30% ethanol, Mobil 91 has 10% - tested, Shell 91 has no ethanol - tested. We digress, everyone will have different fuel depending on sale region and season. I like the VooDoo 702 numbers, but how steep is the lobe slope - i.e. cam wear? Comparing to the Lunati 10100276?

|

Posted By: Halvard

Date Posted: Jan/23/2020 at 12:47am

|

Thank's for the input Greyhounds_AMX. Even if you are talking about flat tappet, there is always something to learn from your posts. As a round of to the octane discussion, there is a difference in octane when it comes to USA vs Europe. In Norway we have 95 and 98 octane. Not everyone is offering 98 anymore and it is a bit more expencive, so it would be beneficial to be able to run on 95. Back to cams: Bullet stands behind their suggested cam after I asked about less duration, more lift and a wider LSA: .520/.520 lift 296/301 adv 238/242 @.050 111 C/L + 4 adv Rpm 2000 to 6000 Bullet: " I kept the LSA to help on torque. The 580 lift would be ok if your turning more than 6500 rpm if even the head will flow that much. The cam will have a good sound to it. " I have still not heard back from Crane. I did'nt even get an auto reply that they received my query, so I guess I have to call them and see if anyone can find the web form I submitted...

|

Posted By: Shawn_Watson

Date Posted: Jan/23/2020 at 9:02am

|

It's a shame that Comp doesn't offer a "Thumpr" hyd/roller in the mid/upper 280s for AMCs. That would be the hot ticket for what you're doing if a custom grind is off the table. Shawn

|

Posted By: Halvard

Date Posted: Jan/24/2020 at 1:03am

| That is probably the complete opposite of what I am looking for and what is discussed in this thread. |

Posted By: Greyhounds_AMX

Date Posted: Jan/24/2020 at 12:47pm

Since he's already running an Extreme cam from Comp with no problems and mentioned he was kind of hooked on them now, I figured the VooDoo would be acceptable to the OP. The VooDoo 702 intake lobe has a slightly less aggressive ramp than the XE256H, while the VooDoo 702 exhaust lobe is slightly more aggressive than the XE256H. The VooDoo 702 is 265/271 @ 0.006, 220/226 @ 0.050, 112 LCA, 0.507/0.527 lift, and ground specifically for 0.904 lifters.

------------- 1968 AMX 390 w/T5 |

Posted By: Halvard

Date Posted: Jan/27/2020 at 1:34am

|

So I got a pretty good reply from Crane on Friday. Really like that they took the time to reply with some reasoning behind the advised cam choice they made. Cam 1 is adviced by Crane, 4 is Bullet and 8 is Comp Cams. The variety is surprising... I am going a bit back and forth, but am now leaning towards the HR224 again. Since they advised even smaller, it feels a bit risky to then go for the 232.

|

Posted By: Brad

Date Posted: Jan/27/2020 at 6:16am

|

I just finished assembly of my 401 last fall. Haven't started it yet but I went with a custom Bullet cam. They were really good to work with, one stop shopping , hyd roller cam, lifters, springs retainers and locks. Hope to get it fired up this spring. My engine is pretty much stock other than the cam. Intake

225 @.050” .330” lobe lift, .528” with 1.6 rocker 278 duration @.006” Exhaust 230 @.050” .335” lobe lift, .536” with 1.6 rocker 285 duration @.006” 113 lobe separation 108 intake centerline |

Posted By: cone

Date Posted: Jan/27/2020 at 6:43am

------------- 1987 J20, 87 Grand Wagoneer,70AMX, |

Posted By: mbwicz

Date Posted: Jan/27/2020 at 8:48am

|

Halvard, I think that the most interesting thing from this chart is that Crane and Bullet both list a RPM range of 2000-6000 for very different cams. Bullet has an additional 12 degrees of intake and 10 degrees of exhaust duration, which would also include a significant increase in overlap. So you are seeing that opinions are like elbows, everyone has a couple. Personally, with 10:1 compression and aluminum heads, I would not go with a smaller cam than what you already have. If your looking for more power at a higher RPM range, you will need to give up a bit of low end power. It is interesting that the gear shift you mention in your first post almost matches the power range of the 232 cam. ------------- 1970 AMX, one step forward, one step back. Both steps cost time and money. |

Posted By: Shawn_Watson

Date Posted: Jan/27/2020 at 9:38am

|

^^^Exactly^^^ And he could call all of them back next week, talk to a different rep and get four completely different opinions. Shawn

|

Posted By: Shawn_Watson

Date Posted: Jan/27/2020 at 10:03am

|

If this were my engine and I was juggling a cam around the trail, some street thrashing and maintaining a decent idle, I'd look for something like 226/232 at .050 on a 110 LSA. I'd try to maximize the lift afforded by the spring pack on the Edelbrock heads by running an asymmetrical ~.365 lobe on the intake. The exhaust isn't nearly as sensitive to lift so I'd look for a more-gentle, symmetrical lobe ~.340 lobe lift. Bullet has lots of lobes to choose from. Look for "CRA" on the intake and "CRS" on the exhaust, if you can find one. http://bulletcams.com/Masters/HRlobes.htm" rel="nofollow - http://bulletcams.com/Masters/HRlobes.htm Shawn

|

Posted By: amcenthusiast

Date Posted: Jan/27/2020 at 10:20am

|

IMO, all the nuances of what cam is irrelevant; ditch the Performer intake. The intake runners are too darn small for any higher performance short rod ratio big bore engine. Sell the Performer to someone with a 304 who does not know how to tune a carburetor: that's what it's made for. ---------------------------------------------------------------------------------------------- But with regard to your sincere question, Dear Sir: Any type of roller lifter cam will cost more than 'newbies' are misled to believe, not knowing the engine needs to be re-engineered for a roller cam system. With only a few rare exceptions, most 'modern' 'flat tappet' lifters actually function like a ball bearing riding on a one sided 'v-groove' track. This type of motion derives from the lifter having an approximate 36" radius 'lifter face' riding upon a cam lobe with carefully ground 'lobe taper' -technically, it's not flat at all: IE: Picture a ball bearing riding in a 'v-groove' track, or 'bearing race'. (Now picture a huge 6 foot diameter ball bearing, but slice a .904" wide section off: that is the face of the lifter.) Now take one side of the 'v-groove' track off. This causes the ball bearing to spin as it moves down the track. There is no 'flat on flat' rubbing motion. The movement ensures 360 degree lubrication of the cylindrical lifter, to prevent 'galling' due to uneven side to side pressure (if the lifter did not rotate) There's also a very subtle nuance of how the rotating lifter 'draws' oil into the contact surfaces between the lobe and the lifter face. Not only does the rotating lifter spread out the wear pattern, the rotation positively brings lubrication along with it, into the contact surfaces. (similar thing happens with a flat rocker tip rubbing on a positive rotating valve stem) Cam lobe taper ensures the correct cam thrust orientation. -All of the lifters are angled in such a way so the cam is thrust gently rearward into the engine block -this is why the AMV8 has no cam thrust plate. (AMV8 is designed with what is called 'cam thrust right' -the name is such by looking at the engine from the US driver side where the cam thrust pushes to the right, into the rear of the block -increasing valve spring rate increases cam thrust and vice-versa -it's all highly engineered; that's what engineers do!) Since AMV8 is not engineered for roller cam system, many revisions need to be made in order to properly adapt the alternative technology. #1) The front of the cam needs a cam thrust plate installed to control 'cam walk' because a roller cam can't have lobes with 'lobe taper' (the roller lifters can't spin in their bores and create proper cam thrust) #2) Heavier roller lifters will need heavier valve springs to prevent 'lifter loft'. Where AMV8 cam bearings are already marginal, I would advise grooving the cam bearing journals in order to facilitate installing cam bearing lube holes in the two o'clock position. -in order to handle the increased load of higher rate 500+ lb springs. (engines that don't feature a .904" diameter lifter are better candidates and the roller lifters will be lighter, nevertheless they'll need revisions as well -to 'do it right') #3) There is another unseen up front cost requiring non rotating valves, because roller tip rockers should be used along with 500 lb+ rate springs, therefore valve stems should not rotate, so they will need to be replaced also (new single groove valves, locks, retainers, springs etc) ($ x 16) #4) Because the heavier roller lifters will require 500+ lb rate springs, the heads will likely need to be machined to match the new higher rate dual spring sizes. #5) Very likely, the current pushrods will need to be replaced for proper length and stiffness ($ x16) Personally, I can't stand one-size-fits-all sloppy-fit spring retainers; I would recommend having the retainers cut on a precision lathe (no three jaw .001" chuck; must be at least a four jaw lathe chuck) so the retainers actually fit the spring diameters -barely snug, both springs, to control valve retainer rotation and prevent excessive rubbing which shortens the life of the dual (or triple spring) set up. (how a coil spring induces valve spring retainer rotation is an interesting study in itself) Knowing this now, that the entire engine needs to rebuilt to make all the critical changes, this prospect of installing roller lifters in any AMV8 becomes quite a bit more difficult and expensive than it is to simply buy roller cam parts out of a catalog. It all needs to work together as a well orchestrated system, definitely not a case of 'slapping in a roller cam' -far from it.

------------- 443 XRV8 Gremlin YouTube video: https://www.youtube.com/watch?reload=9&v=2DmFOKRuzUc XRV8 Race Parts website: http://amcramblermarlin.1colony.com/ |

Posted By: Greyhounds_AMX

Date Posted: Jan/27/2020 at 1:10pm

I've always liked Crane, but they seem to consistently open the exhaust valve very early. Your existing has an EVO of 67, but that Crane HR224 is opening it at 80 degrees. That's a big change on that event. We know that your current cam works pretty well, but to get higher RPM you'll have to open the exhaust a little earlier. But 13 degrees earlier is a bunch. If you take a look at something like the Brian Tooley Racing Stage 2 Truck cam, interestingly it's got an EVO point of 67 degrees. Granted, that's for an LS engine, but it's a truck application where they don't want to loose the low end. He sells lots of roller cams for trucks though, so he's got a good handle on the requirements. Also the HR224 has an overlap factor of 2.04, which is a pretty big jump over the XE256H. I've got a cam just over 2.0 picked for my AMX, with full expectation of losing enough low end to have to make a gear change. Maybe try shooting an email to Brian - he's got tons of knowledge and contacts everywhere. He could certainly spec out a cam for you. I met him back in the 90's when he was still with Holley and moonlighting his head porting business. ------------- 1968 AMX 390 w/T5 |

Posted By: Sonic Silver

Date Posted: Jan/27/2020 at 2:30pm

|

Posted By: Brad

Date Posted: Jan/27/2020 at 2:51pm

No I used off the shelf comp cams pushrods ( custom length) Yes on the cam retainer, I adapted a chevy retainer. ( machined the timing gear and plate to suit and drilled and tapped a couple holes in the block to suit) Bought it at the local chevy dealer. https://paceperformance.com/i-6484488-10088128-gm-roller-camshaft-thrust-plate-retainer-most-1988-1990-small-block-chevy-engines-zzz-zz2-engines.html" rel="nofollow - https://paceperformance.com/i-6484488-10088128-gm-roller-camshaft-thrust-plate-retainer-most-1988-1990-small-block-chevy-engines-zzz-zz2-engines.html

|

Posted By: Heavy 488

Date Posted: Jan/27/2020 at 7:04pm

|

To possibly answer a question a few posts back. My last crane purchase was 2 years back for an LS truck cam and the advertised numbers were @ .004" |

Posted By: Halvard

Date Posted: Feb/11/2020 at 1:38pm

|

Things got a bit delayed, but finally ordered the Crane HR216 today! Hopefully it and springtime will arrive shortly...

Cranes advise matched well with the local machine shop, so went for the small one. |

Posted By: PROSTOCKTOM

Date Posted: Feb/11/2020 at 10:33pm

|

Good Choice Tom ------------- Molnar Technologies Full Service Dealer - Crankshafts & Connecting Rods 1969 AMC Rambler Rouge Race Car 1974 AMC Hornet Hatchback, Wally Booth Outlaw Nostalgic Pro Stock Race Car Project |

Posted By: Greyhounds_AMX

Date Posted: Feb/12/2020 at 8:33pm

|

I like it too - it's very very close to being a roller version of the Voodoo 702. And Crane makes good stuff. ------------- 1968 AMX 390 w/T5 |

Posted By: Jims69

Date Posted: Feb/17/2020 at 7:40pm

| I’m not going recommend any lift or duration but I will say greyhounds AMX finally said what I was gonna say, you need a cam that takes advantage of the .904 lifter diameter. Comp cams are Chevy grinds and although they may run good something that is ground to take advantage of the .904 will run better. I had a Ultradyne custom ground for my 390 which is Bullet cams. That is the way to go. Give up a half hour of your time to be with tech on the phone and have your info in front of you and you will get a good cam recommended to you. |

Posted By: Heavy 488

Date Posted: Feb/17/2020 at 7:48pm

| Comps off the shelf are usually Chevy lobes. They also have a list of .904 specific lobes that you can custom grind from. |

Posted By: Halvard

Date Posted: Apr/13/2020 at 6:16am

|

So things are finally moving along, but we hit a snag halfway into the install. I decided to go for the Chevy anti walk plate solution. Unfortunately I had not done enough research, and it turned out we were a bit hasty when we machined the old sprocket. We just took of what the new plate added, not leaving the center area on the sprocket that would slide into plate. I am now looking at buying the kit from Alfano Performance. Any tips are welocme. Also turns out Crane sold me push rods that are too short, so have to get a new set of those as well. Looking to get some solid Brian Tooley ones. Looking at what appears to be in stock at Summit, hoping I'll get it to Norway before the weekend. Unfortunately not able to post pictures yet. Links below: https://1drv.ms/u/s!Asj2vFAlrDV2rBpHVKjAE4t1fMm4?e=nTghGI https://1drv.ms/u/s!Asj2vFAlrDV2rBmMzggEmgzChbuJ?e=Xh1fg0 https://1drv.ms/u/s!Asj2vFAlrDV2rA9wZLEX-tXLw-dg?e=u40OZK |

Posted By: Halvard

Date Posted: Apr/27/2020 at 7:08am

|

And it is finally done. After the mess with the first try at making my own anti walk setup for the cam, I called Nick Alfano at Alfono Performance. Great guy and excellent service! Talked general AMC stuff for an hour and ordered his anti walk kit, new cam gears and he ordered the correct push rods for me so I could have it all shipped as one package to Norway and save some money. He followed up several times to make sure everything was correct and that I got the parts as fast as possible. Perfect clearences on the parts we installed, and have never seen the distrubutor slip in as easealy as it did this time.   ------------- Halvard Jeep CJ-7 AMC401 SM465 |

Posted By: Halvard

Date Posted: Apr/27/2020 at 7:15am

|

Of course the weather turned after it was finished. Drove the Jeep home Saturday night. 1.5 hours in just above freesing temperatures. That is not enough to get the engine up to a temperature where the EFI self learning kicks in. It feels like it is running a bit rich at the moment, and hopefully that will get tuned in by itself. The cam swap has not been the big change I was hoping for, but hopefully some tuning will get it there. I set the timing to 17 initial. Total is 32. Vacuum on top of that (ported). If I remember correctly I had it on 20 and 35 before the cam change. Does that sound OK for this build?

------------- Halvard Jeep CJ-7 AMC401 SM465 |

Posted By: 71amx

Date Posted: Apr/27/2020 at 7:54am

|

Thanks Halvard. Glad I was able to help and it all worked out for you in time to enjoy it this weekend. I never get info from this forum so I didn't know it was still active. ------------- Alfano Performance 4849-76 st Kenosha, WI. 53142 262-308-1302 71amx@sbcglobal.net |

Posted By: BassBoat

Date Posted: Apr/27/2020 at 10:00am

|

I'm a believer that the more advance the better. In general a bigger cam likes more advance to improve the low end. I would go back to the 20 and 35 if it worked well there before. |

Greyhounds_AMX wrote:

Greyhounds_AMX wrote: