|

|

Your donations help keep this valuable resource free and growing. Thank you.

|

Headlight relay harness |

Post Reply

|

| Author | |

lover boy

AMC Fan

Joined: Nov/17/2017 Location: Florida Status: Offline Points: 19 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Headlight relay harness Topic: Headlight relay harnessPosted: Nov/18/2017 at 5:55pm |

|

Anybody using relays to take the load off of headlight switches, dimmer switches, A/C switches, firewall bulkhead ?? I can build a custom relay harness to solve these problems. My headlight harness can be mounted under the battery box for a clean look, or anywhere you want to mount it. I'm retired so I don't do this as a business, just a hobby to stay busy. I have been doing mainly Mopar, But AMC is family.

Anyway, I can't post pics till I have 30 posts, so message me if interested. |

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Nov/18/2017 at 7:01pm Posted: Nov/18/2017 at 7:01pm |

|

We have an area for new product intros, etc- LOL - I'd have to look again to see what it's called exactly, sorry.

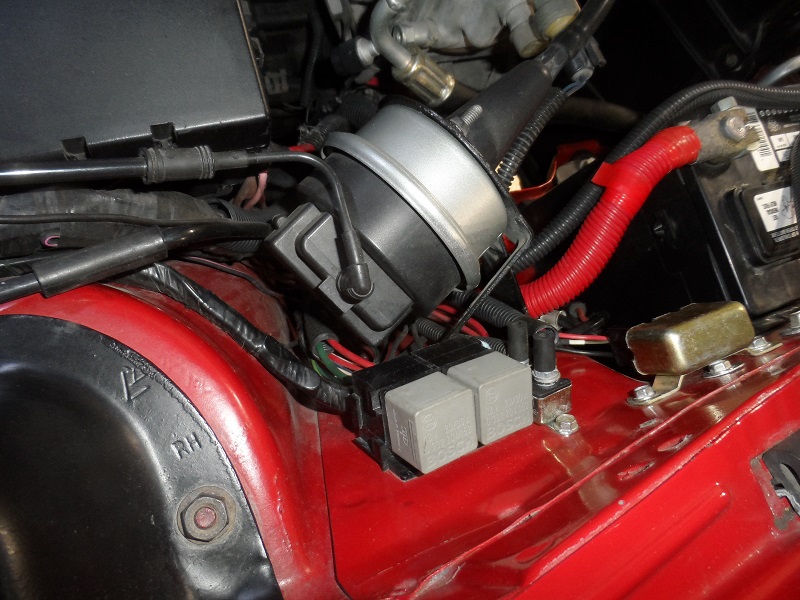

1982 Eagle SX4 - I made a nice harness with new heavy-duty connectors for the headlights and spade connectors to take the relay trigger from the original headlamp connectors. I have the headlight ground behind the horn relay which is just inches from the battery ground to chassis. I left the original wiring in place just in case.......... and used a circuit breaker for the headlight relays.   |

|

|

|

pacerman

Supporter of TheAMCForum

Joined: Jul/03/2007 Location: United States Status: Offline Points: 9057 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Nov/18/2017 at 7:25pm Posted: Nov/18/2017 at 7:25pm |

|

Very nice, Bill. Looks factory. Joe

|

|

|

Happiness is making something out of nothing.

|

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Nov/18/2017 at 8:16pm Posted: Nov/18/2017 at 8:16pm |

|

THANKS, Joe.

My goal with the whole car as far as "non-factory changes" was to make it look like "what if AMC had done this". I've even had AMC people come up and muse "I didn't know AMC did this" or "I didn't know AMC put the 4.0 in Eagles". The headlight relay bit was in answer to a wiring situation with over 180,000 miles and how many years, ten of them sitting in the CA sun. AMC used 18 gauge wire and the wires were old, connections old - you know the drill, obviously! A couple of people have asked me about the black bits sticking up from the breaker - and I suggest "have you ever had a wrench or screwdriver make contact with............"  Call those Bill's safety guards. It's crowded as heck under an Eagle hood with the extra vacuum can, hydraulic clutch bits and so on, but add in the 4.0 with the full Jeep PDC and computer and more and I had to be creative mounting things like the Jeep cruise and the headlight relays - which I wanted close to the battery of course. |

|

|

|

DaemonForce

AMC Addicted

Joined: Jul/05/2012 Location: Olympia, WA Status: Offline Points: 1070 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Nov/19/2017 at 10:33am Posted: Nov/19/2017 at 10:33am |

|

You shouldn't have the full Jeep PDC and ECM in the engine bay in the first place. The Jeep wiring bus is for a Jeep. The Eagle engine bay, especially with all the stock equipment is just way too cluttered to accommodate. I found it much easier to integrate the wiring into the Eagle harness and be done with it while eliminating redundant connections to and from the firewall. The only thing I haven't been able to get around to is setting up a Fr-IGN/SW bus bar to give +12v signal to whatever needs it when the switch is on. So far I think that's only going to be the fan controller, so I'll wire that in at the bulkhead connector.

The old ECM location seems to be the ticket for the new one. I threaded everything for that section and the OBDII diag through that one section of firewall on the passenger side. So now instead of hunting for a mounting location for the bulky computer, I'm using that likely inner fender location near the battery for a Flexalite variable fan controller. Your setup looks great but it's so busy I would never be able to get into anything common. Tuneups are already a nightmare with how tight everything is near the A/C pump but this looks worse. I would put a huge red plastic boot over the hot cable since that's really the only thing worth worrying about at this point. The rest is ace and makes me consider getting my cruise control working again, which I probably wouldn't do with the stock vacuum pig that you seem to be using. Come to think of it I haven't had mine hooked up in ages.  I don't even have a body ground from the main cable. How many body grounds are you using? I count only three on mine: I don't even have a body ground from the main cable. How many body grounds are you using? I count only three on mine:• Combined engine ground @dipstick tube • ECM ground behind wiper fluid bottle • Primary firewall ground from bulkhead connector

There should never be a load signal going through the firewall. I recognize this as a source of voltage drops for headlamps in some vehicles and my Eagle for some reason. I'm in the middle of eliminating this problem the hard way. Also updating all my lamps to LED/HID and the Eagle is the worst sore spot for this. The MPFI swap, manual swap and Jeep PDC minimization has gotten me to truncate that section of the harness to a small bus of mini relays for the IGN/SW, Auto-Shutdown and Starter solenoid commands. The only thing I haven't done is leave provisions for some sort of neutral safety mechanism and I'm starting to think it would have been best to leave it for clutch-out in case of attempted theft or actual safety since I plan on eviscerating my ignition switch for push-button. My only real concern is the proper circuit rating for high powered lights. The LEDs shouldn't consume much but I might be using dedicated inverters and I'm not sure how to go about integrating them. At the moment I'm considering running my foglamp qualifier circuit through the parking lamps instead of low beams in case I swap my foggers for some other lighting equipment and don't want low beams on. Does this make sense? Edited by DaemonForce - Nov/19/2017 at 10:50am |

|

|

1971 Javelin SST

American 304 2v | FMX | AM20-3.31 1983 American Limited Jeep 4(.7)L S-MPFI | 1982 NWC T-5M (4.03/.76) | Dana30IFS/35-2.72 |

|

|

|

Lyle

AMC Addicted

Joined: Jul/17/2014 Location: None Status: Offline Points: 772 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Nov/19/2017 at 12:20pm Posted: Nov/19/2017 at 12:20pm |

|

I use relays also in my 69 Javelin but mounted them beside the fuse panels under the dash. They are now 2 x Bussman fuse blocks, one for battery/ignition and one (through ignition relay) for accessories.

No harness changes except splitting off combined conductors at the harness fuse block end. Plenty of room for gadgets if I so desire later. |

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(2) Thanks(2)

Quote Quote  Reply Reply

Posted: Nov/19/2017 at 2:53pm Posted: Nov/19/2017 at 2:53pm |

|

All these years and all of the hundreds of people who have done conversions as I have and you are the very first to diss and suggest it's improper.

The jeep "wiring bus" is for anything with that engine and other items I chose to run through the pdc and PCM. Since I have done this sort of thing since the early 1970s, since I was an early teen, I found it pretty easy, actually. And since there's really nothing "common" to get into, I didn't sweat much. Oil changes - made sure that stayed easy as far as filter access. I can get it from the top (both hands, actually, if needed) or from the bottom. I can even look over the PDC and SEE the filter pretty easily. Dipstick - check - it sticks right up there but in 30K miles, going about three thousand to five thousand between (synthetic oil) even pulling the dipstick isn't a common thing. Tune-ups? Huh? On a 4.0? Naw, pulled the plugs twice in 7 years, mostly as I was curious. They are still like new. So what is there to access? Nothing. There's only a cap and rotor to the "distributor", and a sensor that rarely ever needs touching - even that's simple to remove, though - and you never have to touch it since timing is controlled via PCM. Drop it in, bolt it down, done. (I have two NOS spares anyway) I had no real problems and people have said it actually looks stock/factory. IMO - it's far far better to use new electrical parts that belong with the engine - and have the computer fully control everything from cruise control to voltage regulation, AC and more. The computer controls my Eagle's AC as well. Can't do that with how you did it so you still have AC control, full clutch power at about 4 or 5 AMPS running into the cabin and through the switch and thermostat. Since I ran mine through the PCM, that means the AC clutch power does NOT go through the firewall into the cabin. The AC switch and thermostat simply sends a signal to the PCM to trigger AC control. That means the stat and switch should last almost forever unless either fails for mechanical reasons. My fog lights run via the PDC relay, the electric JEEP fuel pump is controlled via PDC, starter control, all of it. Even the NSS is hooked up via the PCM. Space was freed up by removing the intake heater relay, fog light relay and starter solenoid/relay. The cruise straddles some of the electrical stuff. My engine compartment is no more crowded than many cars now, and it's far more efficient. I have a proper dash "check engine light" or as Jeep called it, MIL light (I used to call the MIL the mother-in-law light as it nagged in the old days) Heck, I even added power windows - and rewired them through relays to save load on the door wiring and switches, power locks - run via relays, so I can fix up my remote lock system. But to say bluntly "I shouldn't have the full Jeep PDC and Powertrain Control Module (PCM) in place is totally baffling to me. It was EASY. Mounting was EASY - ok, the PCM was a bit tricky to figure how to mount something flat to a non-flat surface, but since the PCM never has to be touched and only needs air circulation to keep it cool, i hid it under the right hood hinge area. I can see placing it behind the right kick panel may be an option but I was concerned about AIR FLOW......... maybe that's not a problem, but didn't want to wire it that way and then find out later after burning up a hundred dollar part. Now I have standard Jeep wiring under the hood for many things and have removed the LOAD going into and out of the cabin area. AC - doesn't run clutch power inside. Headlamps - don't run power through switch inside. Foglights - run via factory switch with one tweak and run via RELAY in the PDC. My alternator is controlled via PCM - and runs through the stock TWO 60 amp fuses in.... yup, the PDC. Troubleshooting is pretty simple as it's still mostly Jeep, it's a marriage of Jeep and AMC with the best of both worlds. I have NO REDUNDANT connections - those were removed from the firewall connector when I redid that, as well. There is only one thing I had to "get around" and that was the fact that the PCM was expecting a couple different signals for the cruise, but I solved that with a couple of diodes and a relay. Now I run the stock AMC cruise switch on the TS stalk to operate the Jeep's cruise embedded into the PCM. It means the PCM also handles the fact that I have cruise on a STICK. Since I wired the Jeep's NSS signal wire to the clutch and used a VSS in the system, like Jeep did, and it has the JEEP BRAKE LIGHT SWITCH mounted in a bracket I rigged under the dash, I can press the clutch slightly and the cruise disengages. Press the brake pedal and the cruise disengages, if the engine revs faster than the VSS indicated the vehicle speed is climbing the PCM will - yup, disengage the cruise. Safe as heck and works GREAT. If I'm on the highway in 4th with cruise engaged and decide to upshift to 5th on a level road - but forget about the cruise, no sweat, the PCM handles it. I had room, made room, moved some stuff, replaced some stuff and since the PCM and PDC control so much of the car now, I basically got rid of enough stuff to allow room for those items. And - it's no problem changing oil and getting to the filter, can see and reach it easily. Spark plugs, simple to check except you don't need to for many thousands of miles it runs so clean and perfectly. I can access almost anything. Tune-ups are RARE with a 4.0 so your comment on getting to common things was confusing - what is there to touch? 30,000 miles on it and never had to touch a thing other than routine oil changes, etc. I guess my experience with cars for over 45 years and specializing in auto-electric for nearly as long made it EASY for me for the most part. I even have a MOPAR air filter rigged like factory. "shouldn't have them in the engine bay in the first place." That's your opinion, not a fact. If that's how you want to do it, fine - but don't say mine makes things too hard to get to...... it really doesn't unless I were to have wiring issues involving the PCM and PDC but I tried to keep those simple as well, cutting out or removing extra wires and with the stock connectors, since I have the Jeep service manual I can go right to the exact pin or socket location for anything in any connector under the hood. If I were to do another one, and I likely will as others have asked me if I'd do such conversions in my shop for others, I'd do it almost exactly the same but would re-route some of the wiring a bit differently than I did to save wire and clean it up just a bit more. Coolant recovery tank -  Air filter and washer tank -  PDC - with two 60 amp fuses (stock Jeep setup) for the charging system and I take power from here for the headlight relay breaker, horn and other stuff that USED TO connect to the starter relay on the fender - oops, you can even SEE the oil filter, dipstick, etc., here -  Formed vacuum lines - hardly any rubber hoses at all, to anything. I used Jeep formed lines and even made my own for most vacuum operated things.  Distributor cap and wires in plain view and simple access with ordinary screwdriver. No need to remove anything to get the cap off or pull any plugs at all. Even the back of the alternator isn't too terrible bad to get to - no worse than any other car...... By the way - stock Jeep (1994) AC compressor and stock AMC Eagle lines and hoses, etc. The AC works fine, all that was changed was the receiver/dryer which you always change anyway when a system is opened up like mine was. Jeep compressor controlled by PCM, ORIGINAL AMC Eagle lines and hoses and condenser and evap.  Any extra wiring here? Nope, all that the Jeep system took over for was removed. All that's here is the wiper wiring, signal from AC switch inside to PCM "give me AC" signal line, fog light switch wires to relay in PDC, just the standard stuff with extra removed.  Throttle and cruise cables can be seen, stock air filter hoses, PCV vent line from crankcase to air intake hose - nothing hard to get to on this side unless I need to change the exhaust head pipe, then I'll be praying a bit.......  NO I won't put a funky red boot on the positive battery cable end. You always have to pry them back to get to the post if you want to hook up something, check something (test voltages or drop at specific points) or connect a battery minder, etc. I've used the car to jump others. With the posts visible, I can more easily tell the condition of things, too.  Easy access to check all fluids or add if needed. Can get to air filter fairly easily, pull the big fat air intake hose and unsnap the lid and lift it up. Coolant tank sits in a holder - remove the cap and hose assy, lift the tank out of the bracket - if you need to for any reason -   Rubber lines replaced with plastic molded lines means no soggy soft lines, cracked lines, etc. - only where there's a very short piece of rubber line for the plastic to connect to the item it serves.....  That coolant tank looks like it was made for my car - I wish I had made note of the car I took it from in case I ever need another! I can't recall what sort of car it came from....... does anyone here recognize it?? Was likely a foreign make as that's where I was in the pick n pull lot..........  |

|

|

|

Lyle

AMC Addicted

Joined: Jul/17/2014 Location: None Status: Offline Points: 772 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Nov/19/2017 at 9:29pm Posted: Nov/19/2017 at 9:29pm |

|

Me, not trying to knock authentic or factory original look as exemplifying by Build, very effective. I just wanted a reliable/understandable electrical system that is not in plain site but easy to get to, understand, and in one location. My intent was to build a reliable street driver I was comfortable to troubleshoot and repair. Neither is "factory" correct and both are better then factory "original". Any way a person decides to go, your car, your decision. You have to know what you did if it is not factory original! Future, if you sell it, past it down, the new owner would really appreciate knowing what you did. Have you ever tried to fix a wiring issue when the person used black wiring for everything? Nightmares, just like this forum changing text size for unknown reasons!!

|

|

|

|

rockAMX

AMC Addicted

Joined: Sep/16/2011 Location: Lethbridge AB Status: Offline Points: 985 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: Nov/19/2017 at 11:18pm Posted: Nov/19/2017 at 11:18pm |

|

Easy to use a headlamp relay. I use the one below on my 68 AMX. Easy to connect.

https://www.ebay.com/itm/12V-35W-H4-9003-Halogen-Lamp-Harness-12V-40A-Relay-1-5m-Copper-Wire-Length-Kit/232505415506?hash=item3622671752:g:ZlkAAOSwgYVZzerr&vxp=mtr |

|

|

DWR

1968 AMX  |

|

|

|

Post Reply

|

|

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |