|

|

Your donations help keep this valuable resource free and growing. Thank you.

|

CeC technical information? |

Post Reply

|

Page <1 34567 9> |

| Author | ||

MIPS

AMC Nut

Joined: Mar/11/2019 Location: Kamloops, BC Status: Offline Points: 347 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: Jun/02/2019 at 10:35pm Posted: Jun/02/2019 at 10:35pm |

|

|

I did not actually see the previous mention for the cost of the connector, however now that I know it's....unpleasant. There isn't really much of a work around then except for as you mentioned harvesting existing ones off other CeC's working or not. I think it might just come down to begging the off-roaders to sell their modules if they've removed their system.

My bad if my thought on the fuel tables was wrong. First time really digging into this so I'm trying to still weed out modern car talk from computers and ECU's because MAN every time I expect this to be something complicated it's just something even simpler. Hmm, perhaps there's a way to just initialize the microcontroller with a different idea of what the "ideal" air fuel ratio is? This may require a little bit of experimenting. |

||

|

||

Greyhounds_AMX

AMC Addicted

Joined: Nov/14/2009 Location: Kansas City Status: Offline Points: 1268 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/03/2019 at 6:53am Posted: Jun/03/2019 at 6:53am |

|

|

I'm sorry - I was meaning the cost of a replacement CeC was around $200. I haven't been able to find that connector anywhere.

The only way it could control to a different setpoint target than the 14.7:1 would be if it knew the rate of change of the A/F ratio. But the Lambda sensor doesn't provide that unfortunately, so there's no way to do it. A wideband O2 sensor with electronics package to drive it can be had for about $200 nowadays, which is pretty amazing. But then you'd still need a processor to do the PID loop to drive the carb stepper motor.

|

||

|

1968 AMX 390 w/T5

|

||

|

||

tomj

AMC Addicted

Joined: Jan/27/2010 Location: earth Status: Offline Points: 7544 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/03/2019 at 10:49pm Posted: Jun/03/2019 at 10:49pm |

|

|

A/F ratio isn't measured with a lambda sensor; it's derived, mathematically, from the average over time of lean/rich. that's how GM's TBI does it. with the engine running the system makes a guess (literally a history-based guess) as to what injector PWM value produces correct mix. of course the lambda sensor does produce that; the code does, indirectly. it's easiest to imagine averaging (integrating) the TIME SPENT LEAN vs the TIME SPENT RICH, and if the rtio or those two values is 0.5, then it's stoich. if its richer than that the PWM on time is reduced; if too lean PWM on time is increased. this works because the engine is a big block of metal and moves slowly relative to the sensor and software. the code dances around the slow metal. if you're not a programmer, that's a good intro into how good programmers think up solutions to problems using cheap, crappy sensors. you could "measure" the temperature of a room by turning the wall thermostat back and forth until the furnace went on, then off, etc, frequently. if its always-on the actual temperature is lower than the thermostat, always off, it's hotter. if it switches back and forth it's "close". accuracy is relatively limited, and the derived A/FR lags behind in time aa few hundred milliseconds. certainly "good enough" for the 80's. |

||

|

1960 Rambler Super two-door wagon, OHV auto

1961 Roadster American, 195.6 OHV, T5 http://www.ramblerLore.com |

||

|

||

Greyhounds_AMX

AMC Addicted

Joined: Nov/14/2009 Location: Kansas City Status: Offline Points: 1268 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/04/2019 at 6:57am Posted: Jun/04/2019 at 6:57am |

|

|

In operation, A/F ratio can change almost instantaneously. The time weighting you see used in the control logic is there to add hysteresis around the setpoint so the stepper motor or whatever controls the fuel flow rate doesn't wear out quickly by cycling up and down continuously. Since the Lambda sensor only reports rich or lean and not how rich or how lean, the only way to add hysteresis is based on time.

Engine temperature (or almost any temperature control loop) on the other hand would respond slowly due to the mass of the engine, coolant, etc.

|

||

|

1968 AMX 390 w/T5

|

||

|

||

farna

Supporter of TheAMCForum

Moderator Lost Dealership Project Joined: Jul/08/2007 Location: South Carolina Status: Offline Points: 19676 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/04/2019 at 11:53am Posted: Jun/04/2019 at 11:53am |

|

|

So in reality you guys are on the same page. Yes, A/F mixture can change rapidly, but with a feedback carb (or cheap TBI/EFI) you don't want changes too often or quick due to parts wear and time to function. So "close enough" is the rule... Modern port injection can respond faster, but I bet there's still some lag built into the systems.

|

||

|

Frank Swygert

|

||

|

||

Greyhounds_AMX

AMC Addicted

Joined: Nov/14/2009 Location: Kansas City Status: Offline Points: 1268 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/04/2019 at 12:24pm Posted: Jun/04/2019 at 12:24pm |

|

|

The point to take home is that with a narrowband Lambda sensor like what the Eagle has we're stuck with closed loop operation that's fixed at approximately 14.7:1 A/F ratio.

|

||

|

1968 AMX 390 w/T5

|

||

|

||

tomj

AMC Addicted

Joined: Jan/27/2010 Location: earth Status: Offline Points: 7544 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/04/2019 at 11:12pm Posted: Jun/04/2019 at 11:12pm |

|

|

i wonder what the goals of CEC were. greyhound is correct, the poor stepper would last a month tgrying to update (and would be too slow). maybe altitude and temperature (warmup) compensation? that stuff is slow moving. the carb has the other usual junk doesn't it? accellerator pump and all that? |

||

|

1960 Rambler Super two-door wagon, OHV auto

1961 Roadster American, 195.6 OHV, T5 http://www.ramblerLore.com |

||

|

||

73Gremlin401

Supporter of TheAMCForum

Joined: Mar/02/2013 Location: Stmbt Sprgs CO Status: Offline Points: 946 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/05/2019 at 12:44am Posted: Jun/05/2019 at 12:44am |

|

SFAIK, the stepper-motor doesn't do much other than help to control mixture. the BBD carb itself was augmented differently most every year in response to the prevailing emissions requirements, and the sheer number of BBD variations within a year model was staggering at times. My current driver, a 1980 Concord, has 2 key things hanging off the carb, a throttle 'kicker' that cracks open the throttle at idle when the car is in-gear or with the AC on, and choke is fully off; and a very simple throttle position switch which is looking for an open/closed condition only. I'm guessing that goes to the computer to help it agree with what the 02 sensor is sending it. in 1980 there were still high-altitude/49-state/California carb variations, as well as versions for automatic and manual transmission, as well as several versions exclusively for the Eagles, which were classed differently - so at least 8 versions in that year alone.

|

||

|

73 Gremlin 401/5-spd.

77 Matador Wagon 360/727. 81 Jeep J10 LWB 360/4-spd 83 Concord DL 4-dr 258/auto  |

||

|

||

MIPS

AMC Nut

Joined: Mar/11/2019 Location: Kamloops, BC Status: Offline Points: 347 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/06/2019 at 10:47pm Posted: Jun/06/2019 at 10:47pm |

|

|

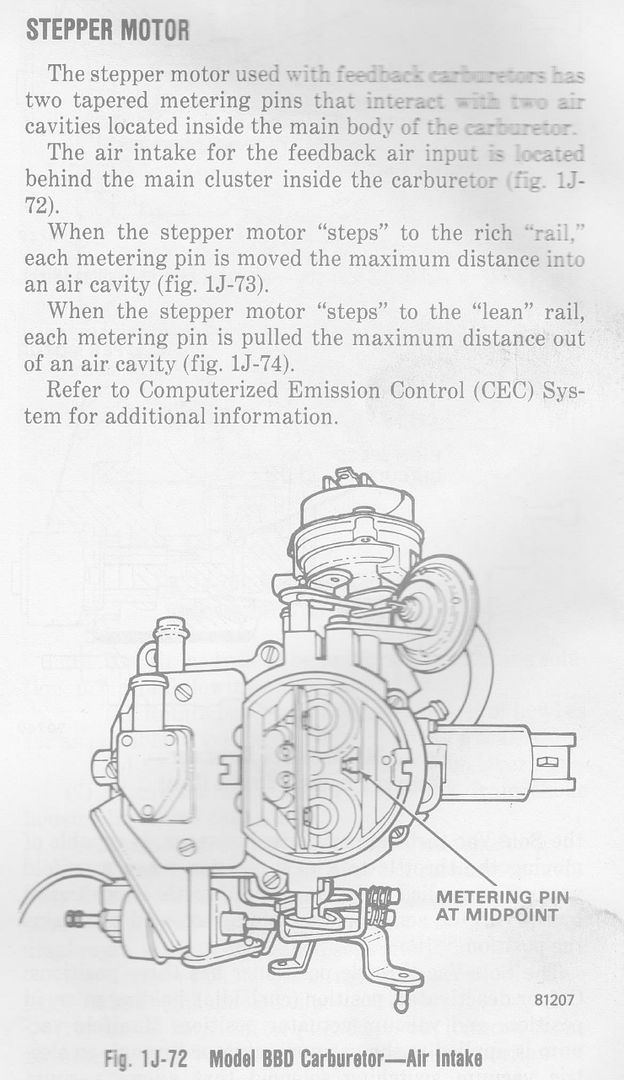

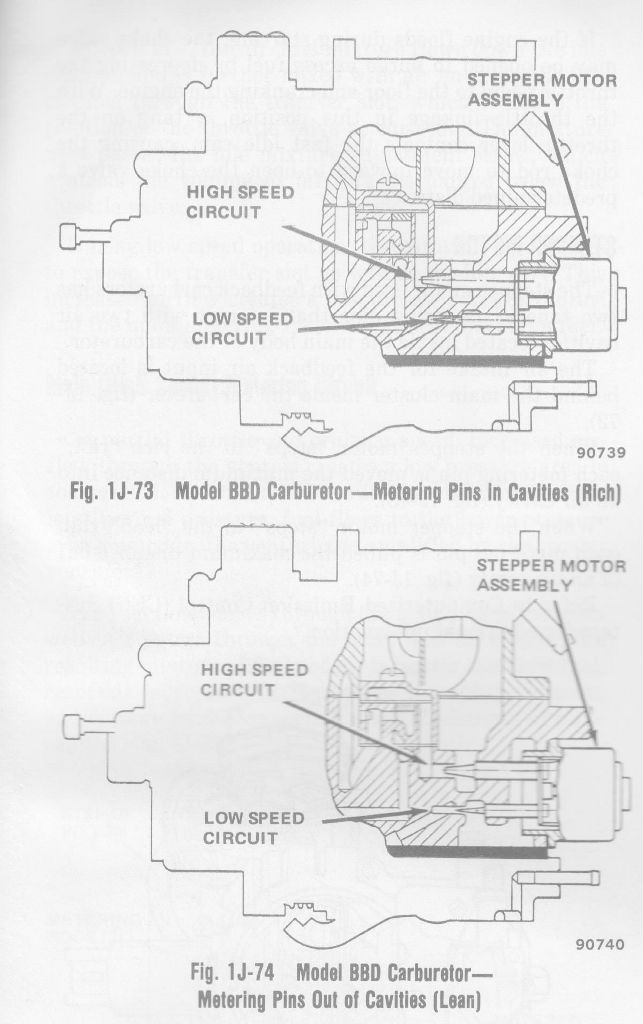

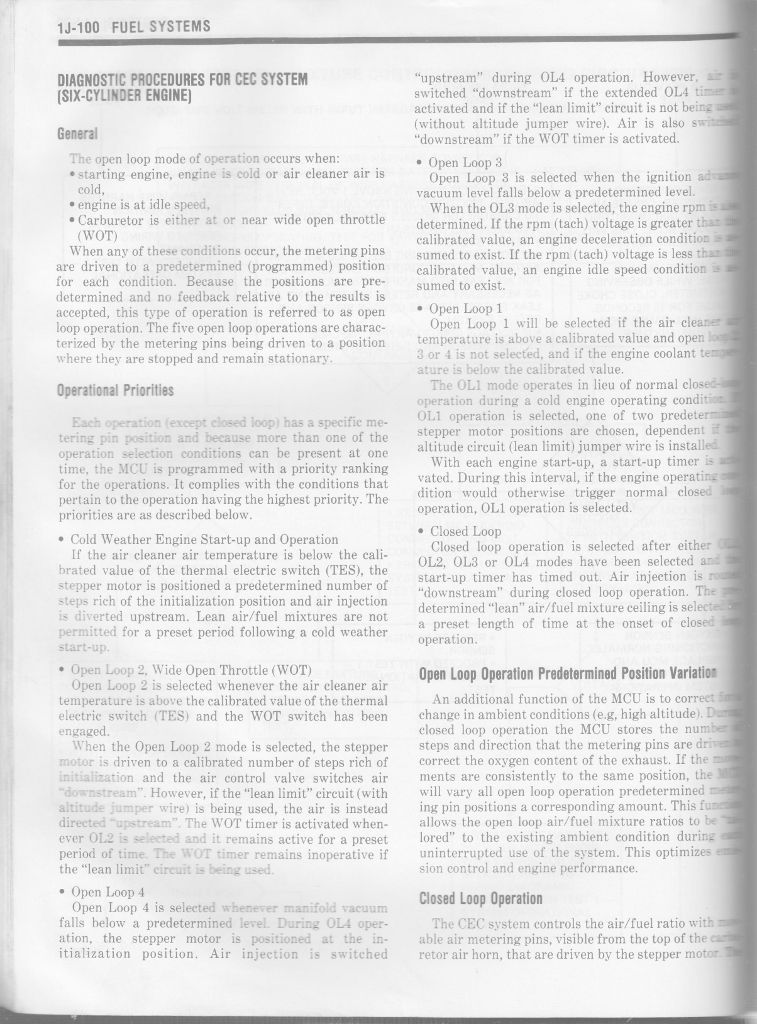

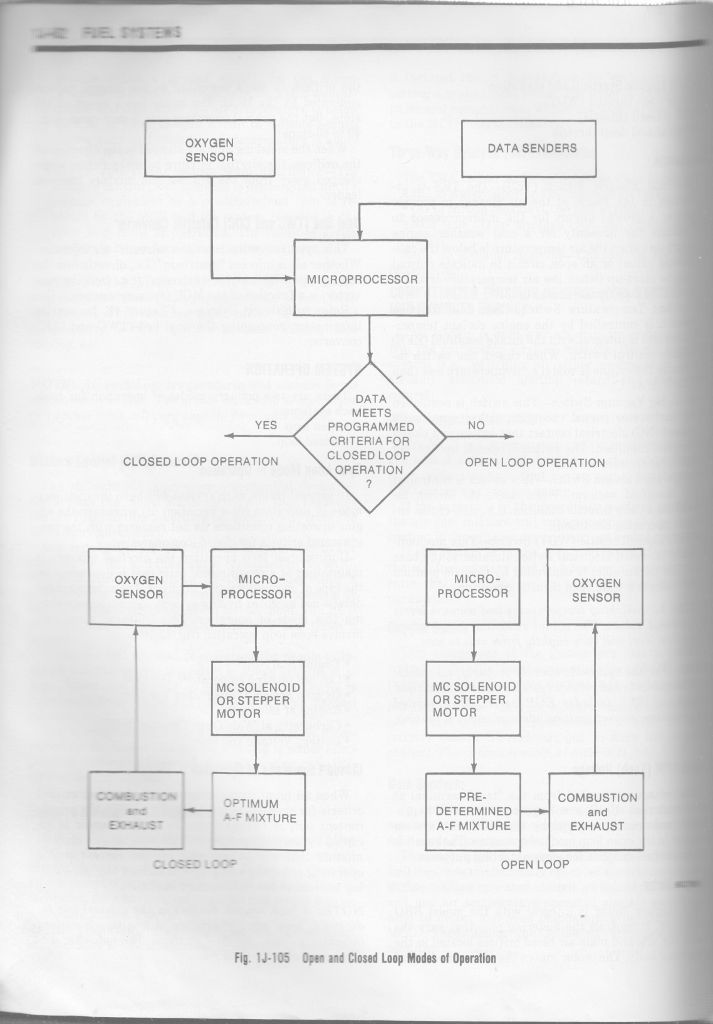

Here's the official stance on how the stepper motor works in the 2BBD. Keep in mind that stepper motors are typically rated for tens of thousands of hours before failure when they are sealed like this. More than likely poor performance of the stepper motor itself can be blamed on lubrication that has gummed up with age as opposed to bearing wear or an open winding.

The first item is the Idle Speed Control Solenoid, or "Sol-Vac". It's a whole circuit that simply bumps the idle up for certain load conditions like you specified, plus can be computer operated when necessary but is not related to O2 sensor operation. The other item is the Wide-Open Throttle switch. Its only purpose is to tell the computer when the throttle plate is within 15 degrees of being completely open. There's more on this below.

Altitide control on the 82 CeC is controlled by a jumper that is either grounded to indicate you are operating above 4000 feet or tied back and not connected to anything, indicating you are working anywhere below 4000 feet. Remember that this is all-digital so the computer can only receive a YES or NO when it is looking at any sensor (excluding the O2 sensor). The computer does not monitor the status of this signal during operation, so it initializes accordingly when it is powered on. Likewise the CeC has multiple open-loop modes it will go into depending on what the sensors are indicating when the computer is powered on. This will also affect where the stepper motor sits and remains while in open-loop.  Once all the sensors satisfy their requirements for closed-loop the computer runs a timer to verify everything remains above spec, then enters closed-loop and from then on it is reliant on the O2 sensor and begins full-time stepper motor operation.  I think I mentioned it before in the thread that a working O2 sensor is ESSENTIAL, otherwise you enter closed-loop and the computer will immediately stick you in a max lean or max rich condition which makes the engine run like crap. A very VERY "you must read this" place to read up on all the related sensors above is http://gleebledorf.com/ It's more oriented for Jeep configurations but Eagle and similar AMC models use otherwise the same components. Edited by MIPS - Jun/06/2019 at 11:37pm |

||

|

||

farna

Supporter of TheAMCForum

Moderator Lost Dealership Project Joined: Jul/08/2007 Location: South Carolina Status: Offline Points: 19676 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jun/07/2019 at 7:35am Posted: Jun/07/2019 at 7:35am |

|

|

"...otherwise you enter closed-loop and the computer will immediately stick

you in a max lean or max rich condition which makes the engine run like

crap." The Nutter Bypass (bypasses the emissions controls) sets the stepper motor in the mid position. Something about when the system is first initialized it starts in the mid position (switch on, engine not running), then adjust rich or lean from there? So you have to have everything connected before removing the CEC system so the carb stays in the mid position. It still won't run as well as a functioning CEC system, but doesn't run like crap because the metering pins are full rich or full lean -- so it runs "better" with the original carb. If you're going to remove the emissions system you need a non-emissions carb, so may as well upgrade to a Weber or Motorcraft 2100. A non-emissions dizzy usually helps as they are curved differently, especially the later models that had some computer timing control .

|

||

|

Frank Swygert

|

||

|

||

Post Reply

|

Page <1 34567 9> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |