|

|

Your donations help keep this valuable resource free and growing. Thank you.

|

73 Javelin brake and suspension project |

Post Reply

|

Page <1 7891011 14> |

| Author | |

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 11:52am Posted: Mar/23/2018 at 11:52am |

|

Why do you like to disagree or argue with everything I'm doing??

Who is working on it, anyway? The lift would be a minor help to me only for under the car - how can it help under the hood? Ya take everything you need down with you and stay until it's done. If it's on a lift you can't even get to the lines on the firewall....... you lean over the fenders for 3/4 of the work. The only advantage is you can stand under the car to do the line from the firewall to the rear axle, then the two on the axle tubes. Or have it half-way up and you can stand next to the wheels and connect the lines to the caliper hoses - but then you have to have it down to run the lines under the hood. The rear are the simple ones and I take everything I need with me - and have no problem laying down for that and getting up one time. The trouble lines are those under the hood against the firewall, down to the combo valve (or pressure differential switch) That is where the up and down, back and forth truly is. If the engine was out - it would be a whole lot easier......... The dual carbs and larger cast valve covers sure don't help on this car - it's tight back there. Luckily the headers aren't in the way. I've probably replumbed either fully or partially over 100 or so......... the hardest part for me is always laying over the fenders and reaching back to the firewall. It's THAT getting up and down that's a pain. I know of a couple of guys who had to quit because of the pressure that over-the-fender work puts on the heart and rib cage. Edited by billd - Mar/23/2018 at 12:02pm |

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 11:59am Posted: Mar/23/2018 at 11:59am |

|

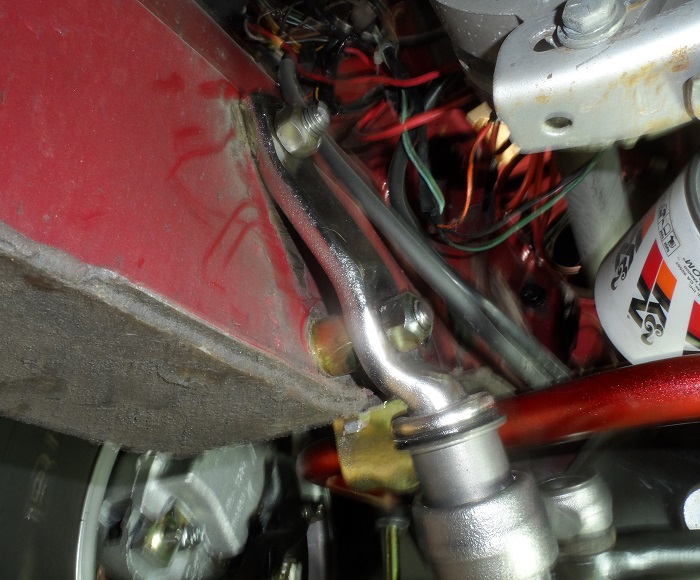

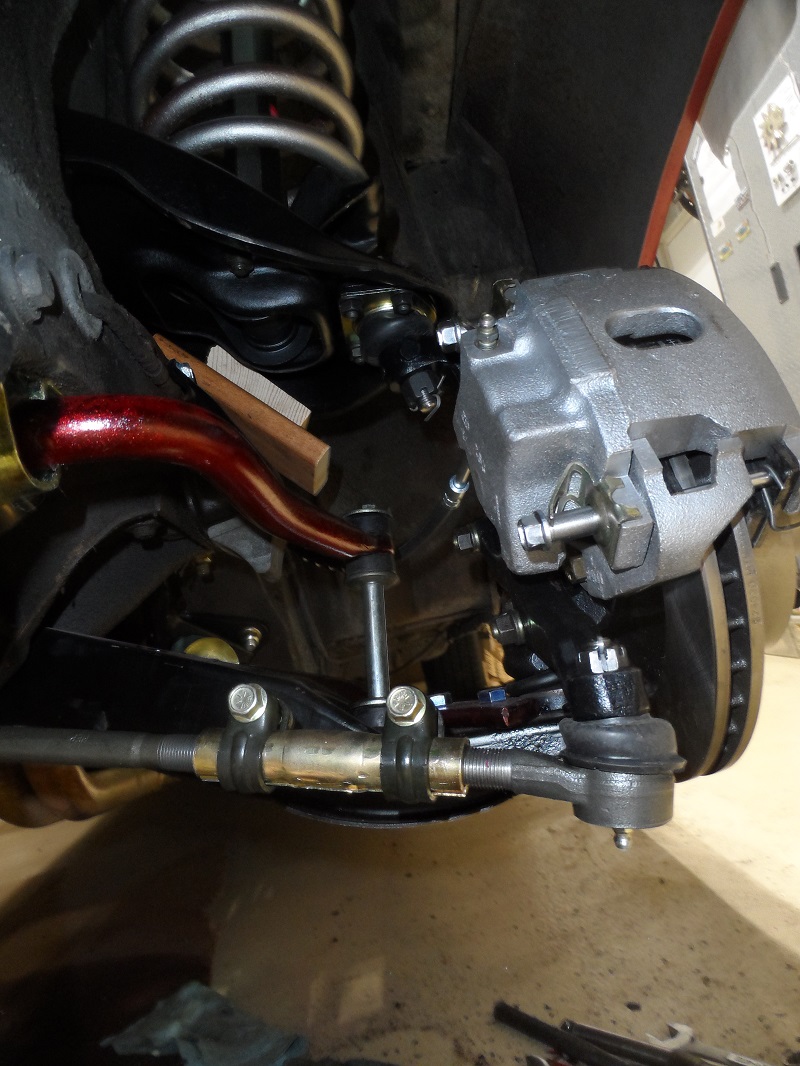

More pics soon - I got the sway bar installed with the new poly bushings. Used standard Moog links at the ends. Drag link is back in and the tie rods installed (by the book - clamps facing up) so the steering is all back together and greased. Ball joints are greased - did that while the load was off both upper and lower and the suspension was hanging. Will tighten control arm bolts when the car is down and springs jounced and settled. Shocks should arrive today. Cleaning up and painting the shock tower tops - the PO cleaned up the tops on the top side and painted them body color when he shot the engine bay but left the bottom sides of them rusty and crusty. Not good at all.

They'll clean up fine, some pitting on the bottom sides but the tops should look fine. So in short, the steering and suspension are nearly done and the brakes will be done as soon as I run the rest of the new lines. Since I'm using line by the roll, I can run one single line firewall coupler to axle tube hose, then one to each rear wheel from the new brass T fitting. Cut, flare, install, all while under the car. Edited by billd - Mar/23/2018 at 12:03pm |

|

|

|

Lyle

AMC Addicted

Joined: Jul/17/2014 Location: None Status: Offline Points: 772 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 12:33pm Posted: Mar/23/2018 at 12:33pm |

|

That copper/nickel line will look good and it's way better to double flare then steel. Looking forward to seeing the pictures.

Have to ask Bill, we were taught to lubricate the back of the flare and the nut threads before assembly. Reason given was to not twist the line when seating it. And to be able to undo easier for the next guy. I have always done this without issue. You have mentioned having many training courses - is this standard practice or just what the instructor of the day thought was best? Other then ensuring you don't contaminate inside the brake system is there any reason not to do this?

|

|

|

|

MD Racer

AMC Apprentice

Joined: Jul/14/2012 Location: Indiana Status: Offline Points: 230 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 2:00pm Posted: Mar/23/2018 at 2:00pm |

|

What did you use to lubricate the threads and flares?

|

|

|

1971 Javelin

1971 Javelin SST 1971 Javelin AMX |

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 2:16pm Posted: Mar/23/2018 at 2:16pm |

|

We never used lube on the flares and threads of the inverted flare nuts - however, I find it an interesting thing to look at. The biggest issue is to avoid contamination and to not make the nuts actually behave differently when you tighten them - in other words, we know what lube does to a standard bolt torque.....

On the other hand, I was ready to use lube on those cursed SS lines I put on my 70 - and then decided "never again stainless". The newer C/N lines are easier to seal, far easier to do a double flare and it's a bit softer so should seal fine - but I did use a touch, and I mean touch, about as much as the oils on our skin, of a brake lube I had around since Hector was a pup (by the way, how old is Hector by now??) Anyway, lube is something I was planning on looking into further. There's no mention of it in any books or materials I have. We did use "Girling grease" on internal parts - the name comes from Girling, the maker of brake and clutch cylinders since the stone age - and the maker of the original clutch cylinders for Eagles. I have wondered if that same stuff may work. I've made two lines so far -been concentrating on the suspension and steering and did those short lines for the right side while things were plating, sitting in the electrolysis buckets or paint was drying, etc. I'm interested in hearing more on the lube apparently a couple of you have used....... Rats, I guess my other books are back up at the house. I found my Bendix guide from 1983 out here and it doesn't give any info at all in that respect. But it shows pretty much all known calipers, pads, and hoses up to 1983, including foreign makes. Pretty cool. I'll look tonight when I get back to the house and see if there's anything anywhere in any of the books or training materials. Lube on the back side of the flare, where the nut contacts the flare, that's an idea I need to look into. |

|

|

|

Lyle

AMC Addicted

Joined: Jul/17/2014 Location: None Status: Offline Points: 772 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 3:12pm Posted: Mar/23/2018 at 3:12pm |

|

We used anti-seize, copper or nickel, didn't matter. Just enough to see that it was there. Told never to use oil as it would possibly run and contaminate the brake fluid. Brake fluid was a definite NO as we were told if it's on your fingers it would get on the paint.

Maybe just a rust belt thing? They sell this though, http://www.jegs.com/i/3M-Products/133/08945/10002/-1 , so somewhere it must be recommended for use?

Edited by Lyle - Mar/23/2018 at 3:36pm |

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 9:14pm Posted: Mar/23/2018 at 9:14pm |

|

I'd not use brake fluid for another reason - its affinity for water, and when left on steel to mix with air and moisture, you get RUST.

Brake fluid, IMO, would promote rust later. Note that any place it seeps onto eventually rusts really bad. We've all seen how boosters look after the master cylinder seeps out the back a bit. Those master cylinders can be evil.  OK, all seriousness aside.......... some pics of the car as it sits tonight. I did refinish the shock tower tops - he had them painted the same as the engine bay - which is the same as the car, etc. AND, I plated the bolts and nuts BRIGHT zinc. those were rusty - one bolt on the left even broke off when I tried to remove it. I got the center punch mark in the center and drilled it one bit size at a time until I hit 1//4" where I could run a tap through and clean it up. Good as new. I did jounce the car around, etc. once back on the floor and tightened up the upper arm bolts - still need to snug up the lower arm bolts but plan on trying to get camber at least close to 0 to start with until I get it aligned. I also show the sway bar - painted, and the brackets zinc plated - man were those rusty and pitted. In some pics you can still see GREASE and oil build-up really bad on certain parts. I NICKEL plated the idler arm bracket, replaced the bushing and painted the idler arm - arm, refinished the nuts, etc.  The drag link cleaned up like new - no rust, no pitting, excellent finish on it. Wish I could have plated it, too - that would have been cool.  Shocks in place.........  I removed the blower so I could get to the brake lines - and remove the old pressure switch, and found the blower motor doesn't turn, by hand it's hard to turn it, and the bottom of the three bolts was broken off - and has been that way for years judging by the rust. But you can tell the PO didn't give a rip because the heater core is bypassed and I am missing a heater valve.   I guess this shows the NOS alternator - one of the pics also shows the NOS regulator I put on a year or so ago.  The nickel plated idler arm bracket - it was dirty and slightly rough so it won't look like show chrome...  Those calipers are close to the wheels - glad there's no weights there, they'd not clear. Oh, and you can see the crud build-up on the frame and parts - I suspect the PS sector leaks, there's several leaks to take care of.   |

|

|

|

purple72Gremlin

AMC Addicted

Charter Member Joined: Jul/01/2007 Location: Illinois Status: Offline Points: 16611 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 9:58pm Posted: Mar/23/2018 at 9:58pm |

|

|

|

|

billd

Moderator Group

Forum Administrator Joined: Jun/27/2007 Location: Iowa Status: Offline Points: 30894 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 10:16pm Posted: Mar/23/2018 at 10:16pm |

|

You'd likely have trouble reaching these brake lines - it's hard to tell from the photos but it's one of those lean way in and reach between engine and firewall with a small ratchet and using a lot of patience, remove the screw and clamp.........

I'm going to try to go back with new lines in the same place. A lift would have been nice when doing the brake fitting - as I was sitting for that. That's where there was up and down - sit and fit stuff, not yet good enough, get back up again. There's a lot of finger prints on the bumper - luckily it's attached well. Ha. Unfortunately, however, no lift will help in the engine compartment fitting the new lines in there. I'm ok laying down under the car - it's when I get up that menieres hits me and I have to get up certain ways. But I can stay under there as long as needed. Standing is what gets to my back. The doc said all those years as a mechanic, then farming - all that lifting and carrying. I used to lift transmissions to the bench, 4 cylinder engines I lifted onto the bench without help, and loading seed, bailing hay and straw - it has taken a toll and now standing is a problem as is sitting unless it's a seat or chair that's just right. My back has waaaay too much curve - instead of the 30 degrees it should have, it's got 60. And that's caused nerve issues and disk issues. (I asked about grease fittings but we don't have that technology yet, I guess) The front wheels are on and the car is on the ground, making it a Bit easier leaning into the engine area........ the big issue is these fenders, like the Eagle fenders, and the other javelins, they DENT easily. The left fender has a spot that's "dented in" and won't stay popped back up like it should. But who knows what the PO did - maybe the metal is thin on the top of that fender. Luckily I have a NOS left. Wish I could find a NOS right fender, too. I have a different limited slip differential to put under the car but want to go through it first and totally renew the brakes on it before putting it under the car so that project will have to wait a bit. This engine breaks the tires loose pretty easily and it often seems as if it's spinning just one so I question the differential that's under it, so got another twin grip to go through and put under it - some day..... For now, all I need to do is finish up the brake lines, get it aligned and it's on the road again - Oh, need to install the new PC front seat stuff but that's a different thread. |

|

|

|

purple72Gremlin

AMC Addicted

Charter Member Joined: Jul/01/2007 Location: Illinois Status: Offline Points: 16611 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Mar/23/2018 at 10:39pm Posted: Mar/23/2018 at 10:39pm |

|

|

|

|

Post Reply

|

Page <1 7891011 14> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |