|

|

Your donations help keep this valuable resource free and growing. Thank you.

|

401 Block damage/problem? |

Post Reply

|

Page 12> |

| Author | |

6t8amxetc

AMC Addicted

Joined: Mar/11/2008 Location: Washington State Status: Offline Points: 631 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 401 Block damage/problem? Topic: 401 Block damage/problem?Posted: Jul/29/2015 at 10:52pm |

|

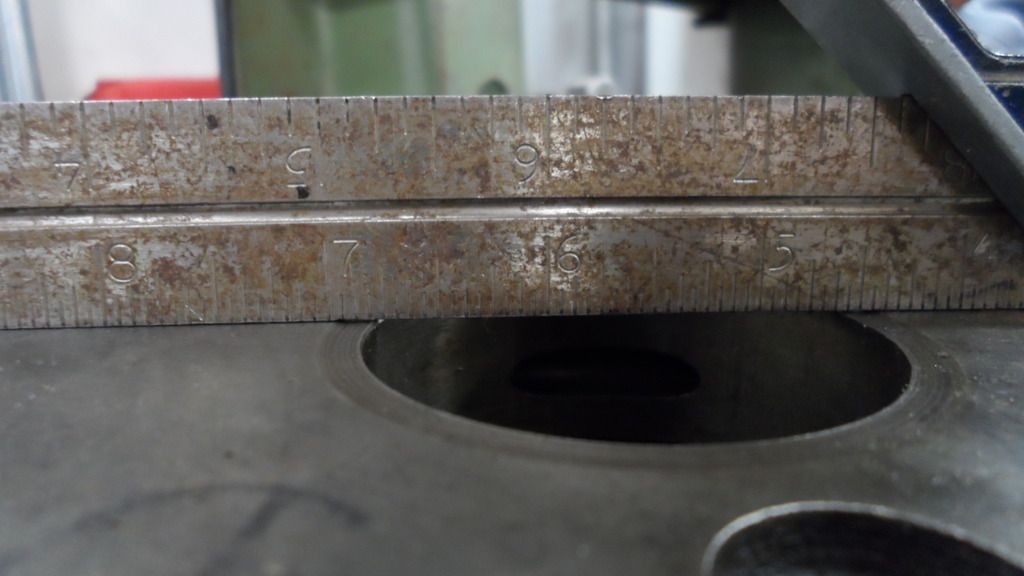

So I have this excellent standard bore 401 block to sell or possibly build. Only problem is the front of the block where the cam gear rides has some wear. Not exactly sure how much of a problem this is? I can't really see what it would affect? Does it need to be repaired somehow? What would it do if run like this? I used the straight edge and could barely get an .009-.010 feeler gauge under it!

Thanks for any input...Ty

|

|

|

|

WARBED

Supporter of TheAMCForum

Joined: Feb/12/2011 Location: Edinburg TX Status: Offline Points: 1683 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 1:29am Posted: Jul/30/2015 at 1:29am |

|

This can be repaired and must be repaired. welding brazing or even a insert would work. EZ fix. Most likely cause would be the wrong cam bolt. (To thick) or someone may have put a washer under the cam bolt. How does the original timing cover look and is the cam stop look ok. Main thing is that you don't want the cam to walk. I think .003 is normal(not sure without checking specs) and .009 on top of that could spell disaster for the distributor gears. (premature wear) On another note, good picture of the oil gallery going to the mains thru the cam journals. now just imagine installing the cam bearings and closing off 30% or more of the flow to the main bearings. This is why I all ways take new cam bearings and champher the outside of the cam bearings to match the flow of the oil passageways. never have had a oil concern since doing this procedure. Also get a 5/16 10 inch long drill bit and clean out all the oil galleries while you have the engine apart. Pay close attention to where the main oil gallery passageways meet the lifter galleries you will get some casting flash from that area. Just don't go to far you can see the drill bit through the open lifter galley. No need for a oil bypass line, it never worked anyways and usually caused other concerns. last note if you don't mind, don't want to be preaching but I've been around AMC engine all of my life, and that includes my terrible two's. When installing the front lifter gallery plugs make sure that they don't block off the oil flow to number 1 cam bearing. If you note from your photos that the oil passageway leading to the number one cam bearing is drilled rate into the threads. I usually clock the plug and then grind that area so there is a smooth transition then I also radius as many of the 45 deg bends that can be accessed in all the oil galleries. time consuming but also piece of mind. Good luck

|

|

|

59 American 2dr S/W. 70 390 AMX. 70 232 javelin. Kelvinator fridge ice cold beer storage.

|

|

|

|

Boris Badanov

AMC Addicted

Joined: Dec/14/2013 Location: NH USA Status: Offline Points: 4209 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 5:11am Posted: Jul/30/2015 at 5:11am |

|

Personally I would just run it.

The cam location along the crank cl is just not that critical. It could be welded or hard chromed then machined, but I do not see a big problem there. |

|

|

Gremlin Dreams

|

|

|

|

401jim

Supporter of TheAMCForum

Joined: Jan/07/2012 Location: Brunswick,Ohio Status: Offline Points: 793 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 6:42am Posted: Jul/30/2015 at 6:42am |

|

Have a steel shim made to compensate for the loss of material. Next it would be a Rollmaster timing chain and gear set. When you see this set you will understand why most of us recommend using it. Good luck with your build......Jim

|

|

|

|

|

|

Rebel Machine

AMC Addicted

Joined: Jul/03/2007 Location: Western Il Status: Offline Points: 5122 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 7:20am Posted: Jul/30/2015 at 7:20am |

|

The Rollmaster timing set has a torrington bearing that might be large enough to make that groove irrelevant. Just be sure to correct the oiling grooves on it.

-Steve- |

|

|

|

WARBED

Supporter of TheAMCForum

Joined: Feb/12/2011 Location: Edinburg TX Status: Offline Points: 1683 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 10:23am Posted: Jul/30/2015 at 10:23am |

|

Hmmm Cam walk has been a concern with AMC engines and other manufacturers. Distributor gears seam to be the first thing to go in most cases. Once the groove or wear mark is remedied and the timing cover is to be installed it would be wise to use a dry gasket on the cover, put some silly putty on the cam bolt, a slight bit of petroleum jelly on the timing cover cam button and torque the cover down. this is to check the end play of the cam. Oh make sure the cam is back as far as possible first and that the rear cam core plug isn't set to far in and pushing on the back of the cam. Personally when rebuilding a AMC V8 engine I machine the cam bolt head so there are no markings and then polish so it is smooth and crowned slightly. Then use a Delron inserts epoxied to the timing cover to limit cam walk. Yes I can be annul but 20 years on my 401 and still running strong. I only had one problem with the engine and that was the cam didn't have a groove cut into the front bearing journal and after years of heavy footed driving it took out the disco gears. ended up machining a groove in the cam and no concerns since.

|

|

|

59 American 2dr S/W. 70 390 AMX. 70 232 javelin. Kelvinator fridge ice cold beer storage.

|

|

|

|

Boris Badanov

AMC Addicted

Joined: Dec/14/2013 Location: NH USA Status: Offline Points: 4209 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 11:12am Posted: Jul/30/2015 at 11:12am |

|

Torrington bearing as in needle face bearing?

Torrington bearing makes all sorts of bearings.... I am not sure I would want a needle bearing running against that surface. IMO the problem is there is no easy inexpensive fix that is better than leaving it alone. Rollmaster sets may be excellent but.... |

|

|

Gremlin Dreams

|

|

|

|

Red Devil

AMC Addicted

Joined: Jul/10/2007 Location: Canada Status: Offline Points: 1743 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 11:32am Posted: Jul/30/2015 at 11:32am |

|

The thrust bearing race sits against the block surface, so the needles don't run on the block.

http://theamcforum.com/forum/uploads/119/AMC-RollMaster-Cam-Sprocket-Backside.jpg Hope this helps,RD. |

|

|

|

6t8amxetc

AMC Addicted

Joined: Mar/11/2008 Location: Washington State Status: Offline Points: 631 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 11:44am Posted: Jul/30/2015 at 11:44am |

|

Lots of good advice and information on this. Thanks guys! Yes, I was wondering about the Rollmaster set. I have these in two of my own engines right now and they are definitely a nice piece. Judging from the pic Red Devil posted it does look like the bearing race would be out far enough to at least mostly clear the damaged portion.

I don't currently have a set I could measure. I will have to try and look up the info somewhere. Also, I don't have the timing cover etc from this block so I can't really check to see if they just used too thick a bolt head or similar? I will most likely end up selling this block but I really don't want to misrepresent anything. Again, thanks for all the suggestions so far...Ty |

|

|

|

WARBED

Supporter of TheAMCForum

Joined: Feb/12/2011 Location: Edinburg TX Status: Offline Points: 1683 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Jul/30/2015 at 12:01pm Posted: Jul/30/2015 at 12:01pm |

|

Oh! In that case the block is toast/unrepairable/How much will you pay me to take it off your hands

. Oh! torrington is a bit overkill but they are encapsulated by a heat treated shell so the bearings would not contact the block surface nor gear, then you'd have to machine the bearing also to compensate. A must for Helical cut gears. If the timing set has a larger footprint then problem solved. . Oh! torrington is a bit overkill but they are encapsulated by a heat treated shell so the bearings would not contact the block surface nor gear, then you'd have to machine the bearing also to compensate. A must for Helical cut gears. If the timing set has a larger footprint then problem solved.Edited by WARBED - Jul/30/2015 at 12:19pm |

|

|

59 American 2dr S/W. 70 390 AMX. 70 232 javelin. Kelvinator fridge ice cold beer storage.

|

|

|

|

Post Reply

|

Page 12> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |